Punching mechanism for automobile reinforcement plate processing

A reinforcing plate and punching technology, applied in metal processing equipment, manufacturing tools, mechanical equipment, etc., can solve the problems of uneven surface of the reinforcing plate, increasing the processing cost of the reinforcing plate, reducing the processing efficiency of the reinforcing plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

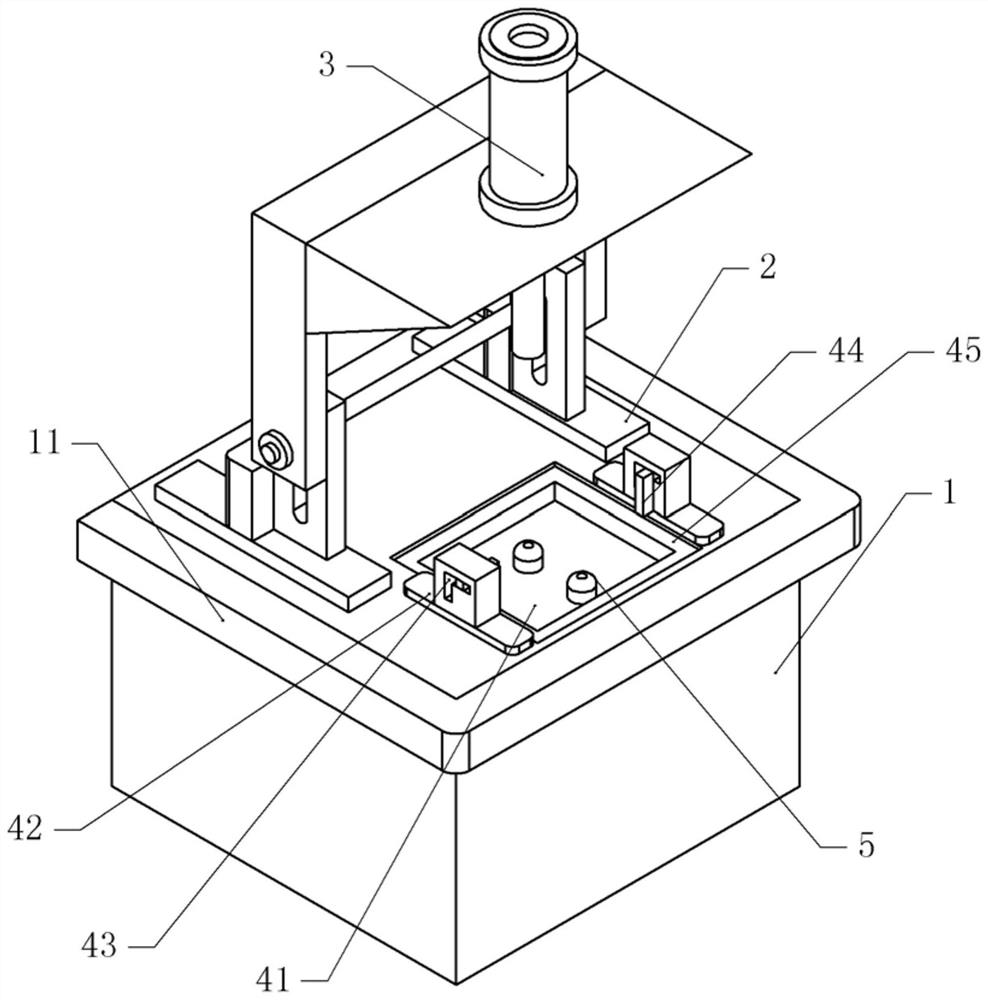

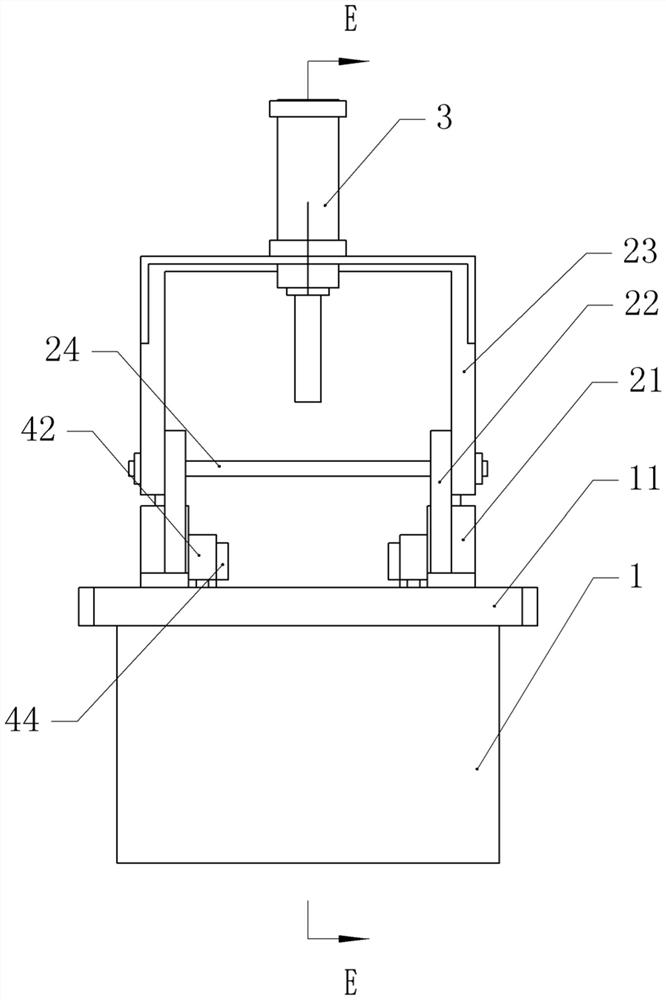

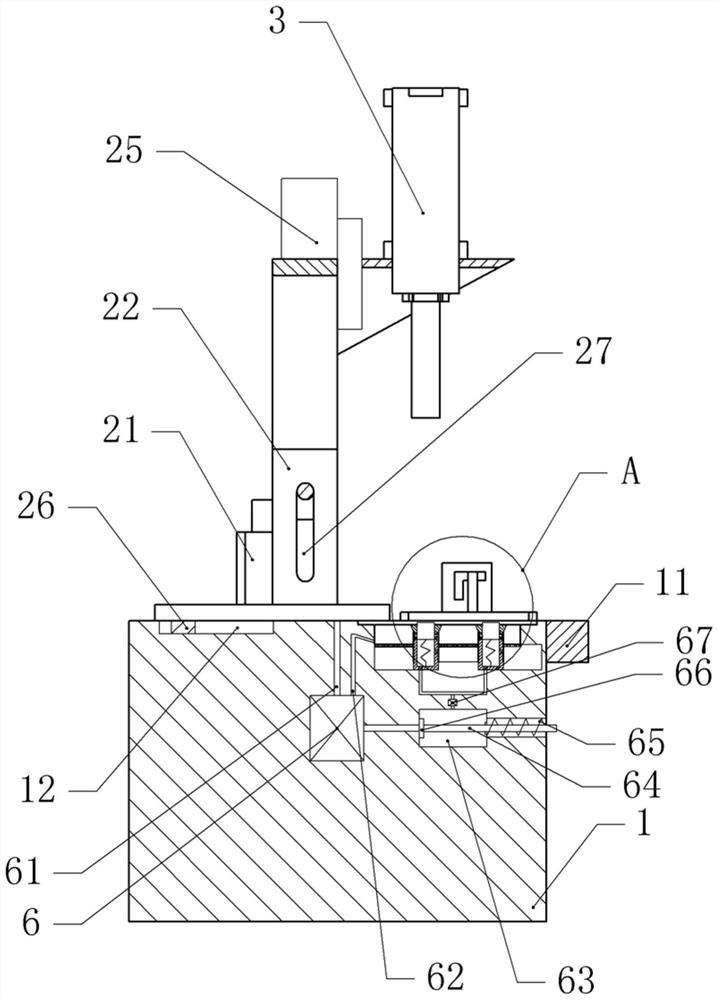

[0034] Basic as attached figure 1 , attached figure 2 And attached image 3 As shown, a punching mechanism for processing automobile reinforcement plates includes a punching table 1 and a bracket 2 installed on the punching table 1 . The punching table 1 is welded with a boss 11, and the boss 11 stretches out from the punching table 1, and the boss 11 prevents the operator from getting too close to the punching table 1.

[0035] The support 2 includes a fixed frame 23 and movable seats 22 positioned at both sides of the fixed frame 23. The bolts on the fixed frame 23 are fixed with the stamping head 3, the bolts on the fixed frame 23 are fixed with the connecting shaft 24, and the movable seats 22 are provided with guide grooves 27. , the connecting shaft 24 is vertically slidably connected with the guide groove 27 . Both sides of the fixed frame 23 are provided with a cylinder 21 bolted to the movable seat 22 , and the output shaft of the cylinder 21 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com