Automobile part spot-welding robot with welding head convenient to replace

A technology for auto parts and robots, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing the processing quality of parts, affecting the normal processing of parts, and collision damage of spot-welded parts. Ensure normal use, ensure processing efficiency, and ensure the effect of spot welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

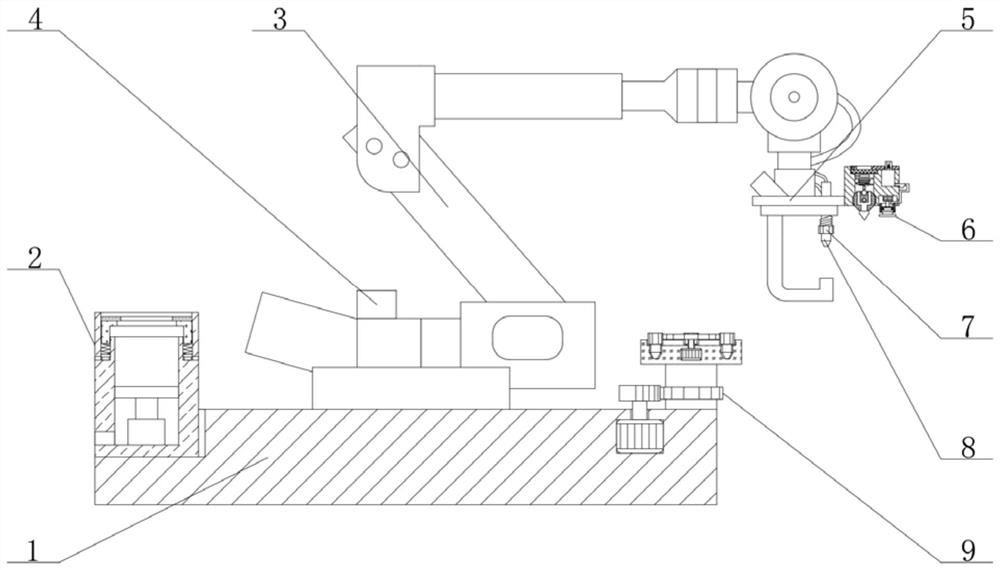

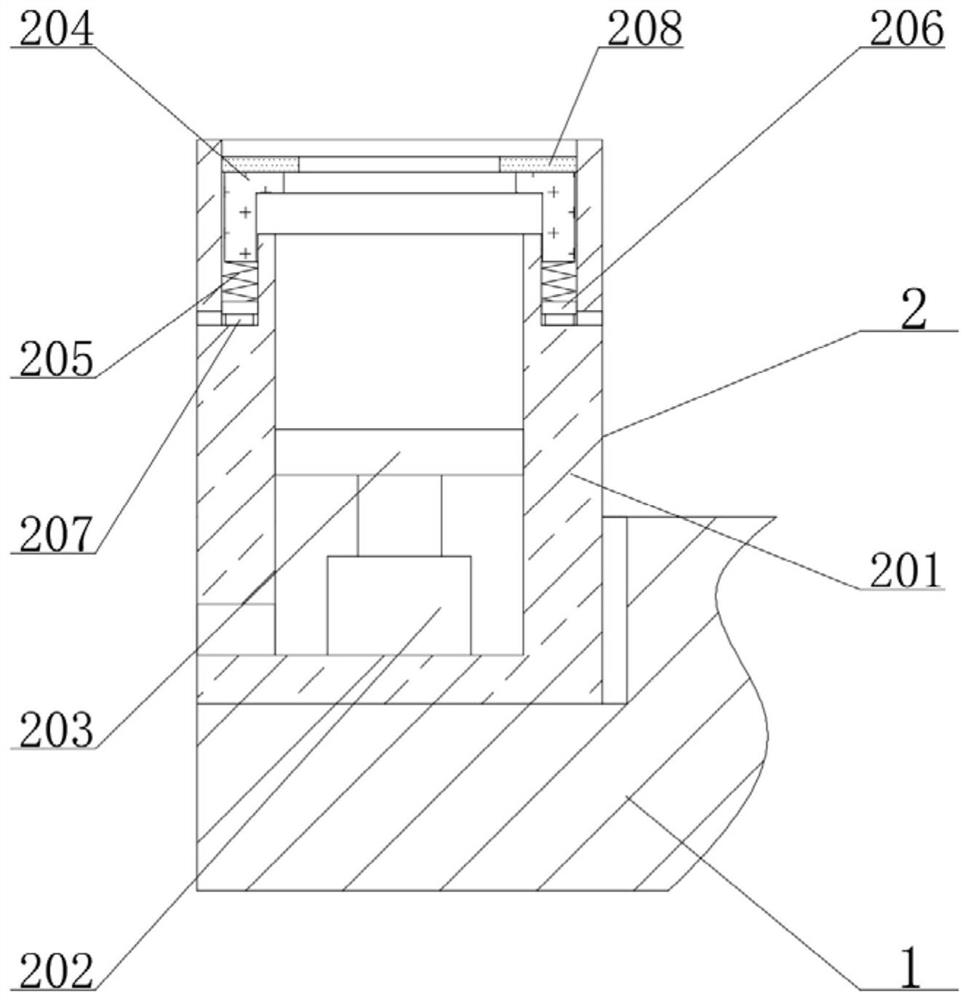

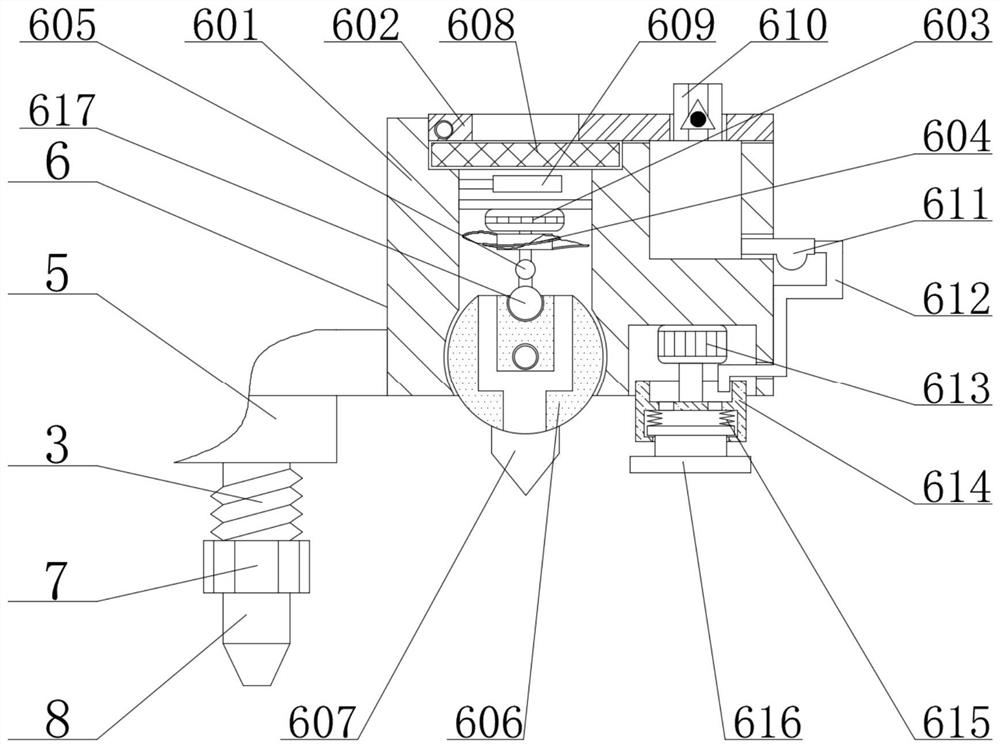

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , the present invention provides a technical solution:

[0031]A spot welding robot for auto parts that facilitates the replacement of welding heads, including a base 1, a protective device 2, a cleaning device 6 and a replacement device 9, a protective device 2 is provided on the left side of the top of the base 1, and the protective device 2 includes a protective box 201, an electric Telescopic rod 202, piston plate 203, sliding frame 204, first spring 205, extrusion ring 206, pressure sensor 207 and washer 208, base 1 top left side is fixedly connected with protective case 201, and protective case 201 bottom end surface inner side is fixedly connected with The electric telescopic rod 202, the top surface of the electric telescopic rod 202 is fixedly connected with the piston plate 203, and the piston plate 203 is slidably connected with the protective...

Embodiment 2

[0034] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , the present invention provides a technical solution:

[0035]A spot welding robot for auto parts that facilitates the replacement of welding heads, including a base 1, a protective device 2, a cleaning device 6 and a replacement device 9, a protective device 2 is provided on the left side of the top of the base 1, and the protective device 2 includes a protective box 201, an electric Telescopic rod 202, piston plate 203, sliding frame 204, first spring 205, extrusion ring 206, pressure sensor 207 and washer 208, base 1 top left side is fixedly connected with protective case 201, and protective case 201 bottom end surface inner side is fixedly connected with The electric telescopic rod 202, the top surface of the electric telescopic rod 202 is fixedly connected with the piston plate 203, and the piston plate 203 is slidably connected with the protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com