Quantitative feed packaging equipment for pig feed production

A technology for pig feed and feed, which is applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of large sanitation and cleaning workload, large packaging and measurement errors of finished products, and many leakage of materials on the ground, so as to reduce the workload of sanitation and cleaning, accurately and accurately. And the effect of fast packing and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

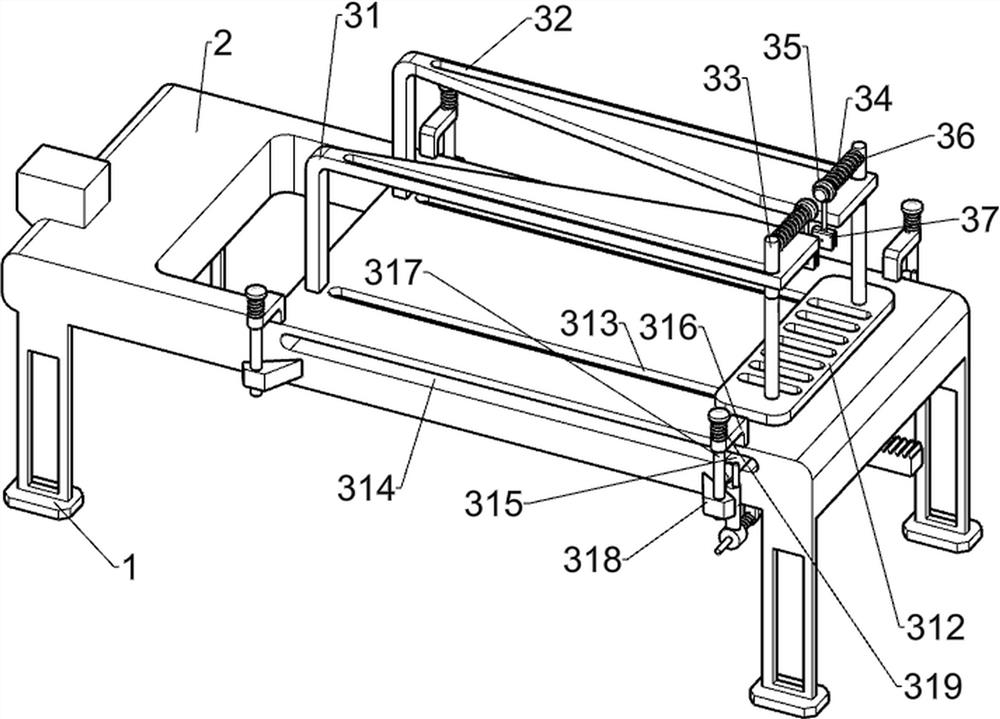

[0025] A feed quantitative packaging equipment for pig feed production, such as Figure 1-Figure 5 As shown, it includes support column 1, workbench 2, packing mechanism 3 and unloading mechanism 4, workbench 2 is arranged between the top of support column 1, the number of support column 1 is 4, and the top of workbench 2 is provided with packing Mechanism 3, a blanking mechanism 4 is provided on the left side of the top of the workbench 2.

[0026] When people need to use this equipment, first people pour quantitative pig feed into the feeding mechanism 4, then fix the bag of feed on the packing mechanism 3, then people can push the packing mechanism 3 to move to the left, wait When the packing mechanism 3 drives the bag to move to the bottom of the feeding mechanism 4, the feeding mechanism 4 discharges the material, and then the feed in the feeding mechanism 4 falls into the bag, and all the feed in the feeding mechanism 4 falls into the bag, and people just Packing mechan...

Embodiment 2

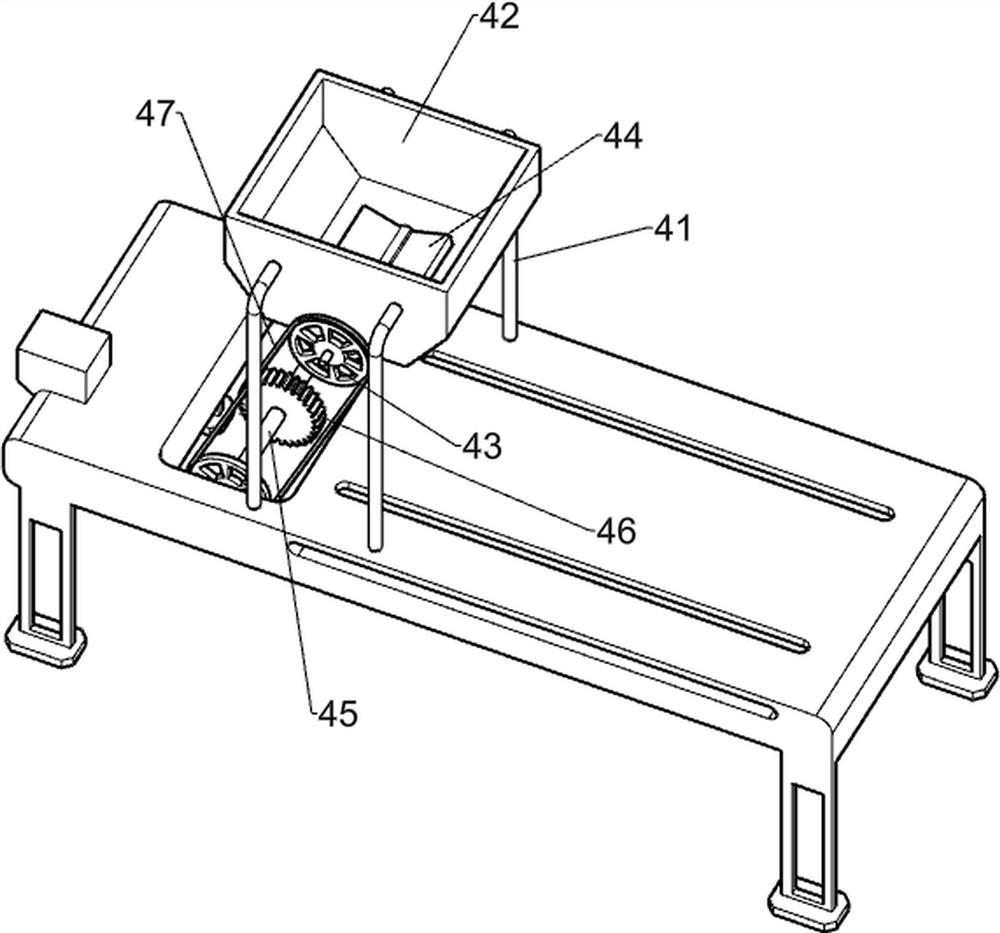

[0032] On the basis of Example 1, such as Figure 6-Figure 8 Shown, also include the second fixed block 5, the 3rd rotating rod 6, projection 7 and flat belt 8, the left side of lower hopper 42 is provided with the second fixed block 5 symmetrically front and back, between the second fixed block 5 with rotating Mode is provided with the 3rd rotating rod 6, and the 3rd rotating rod 6 is provided with a plurality of lugs 7 at even intervals, and flat belt 8 is all wound around by belt pulley between the front and back ends of rotating shaft 43 and the two ends of the 3rd rotating rod 6.

[0033] When the rotating shaft 43 rotated, the rotating shaft 43 drove the third rotating rod 6 to rotate through the flat belt 8, and the third rotating rod 6 drove the bump 7 to rotate. 42 is knocked, thereby the feed in the lower hopper 42 is better leaked out.

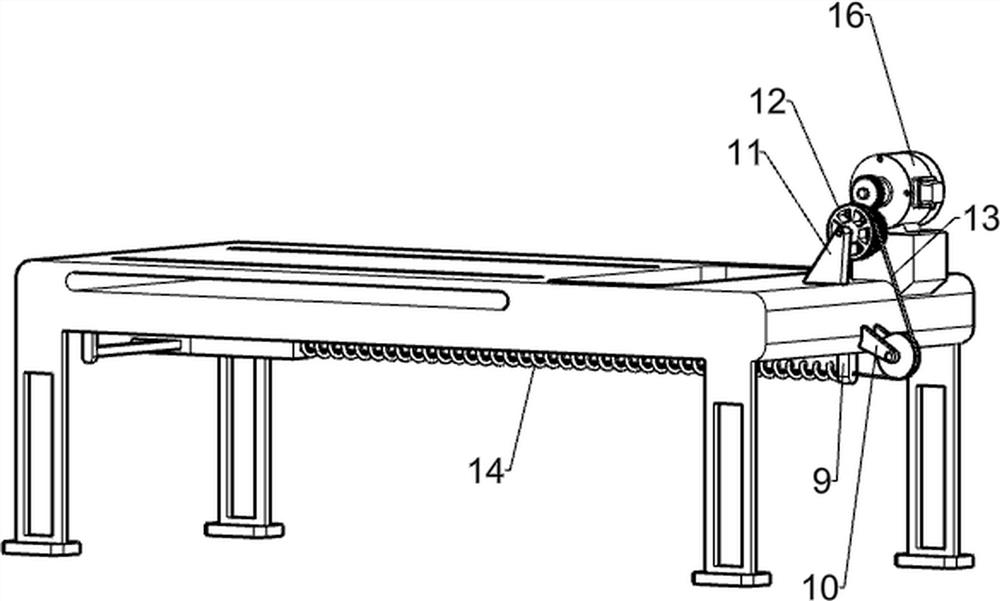

[0034] It also includes connecting block 9, inclined block 10, triangular block 11, reel 12, rope 13, fifth elastic member 14, mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com