Chassis supporting structure of hoisting machinery and crane

A technology for hoisting machinery and supporting structures, applied to cranes, mechanical equipment, springs/shock absorbers, etc., can solve problems such as cranes not working, booms in danger, inconvenient parts replacement, etc., to avoid tilting, Effect of reducing vibration and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

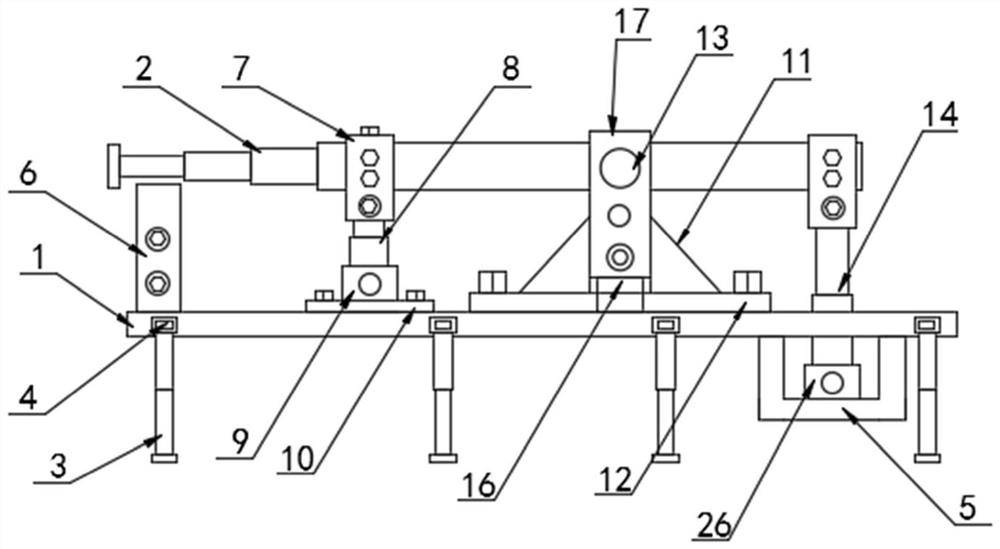

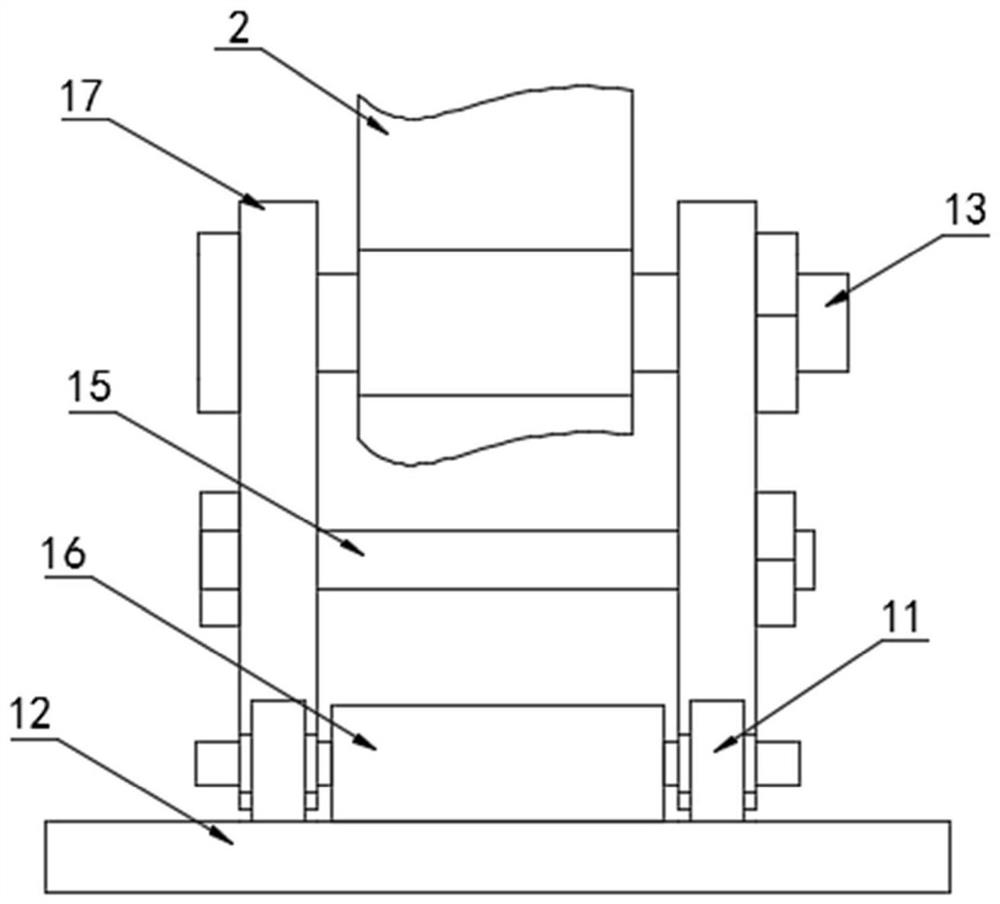

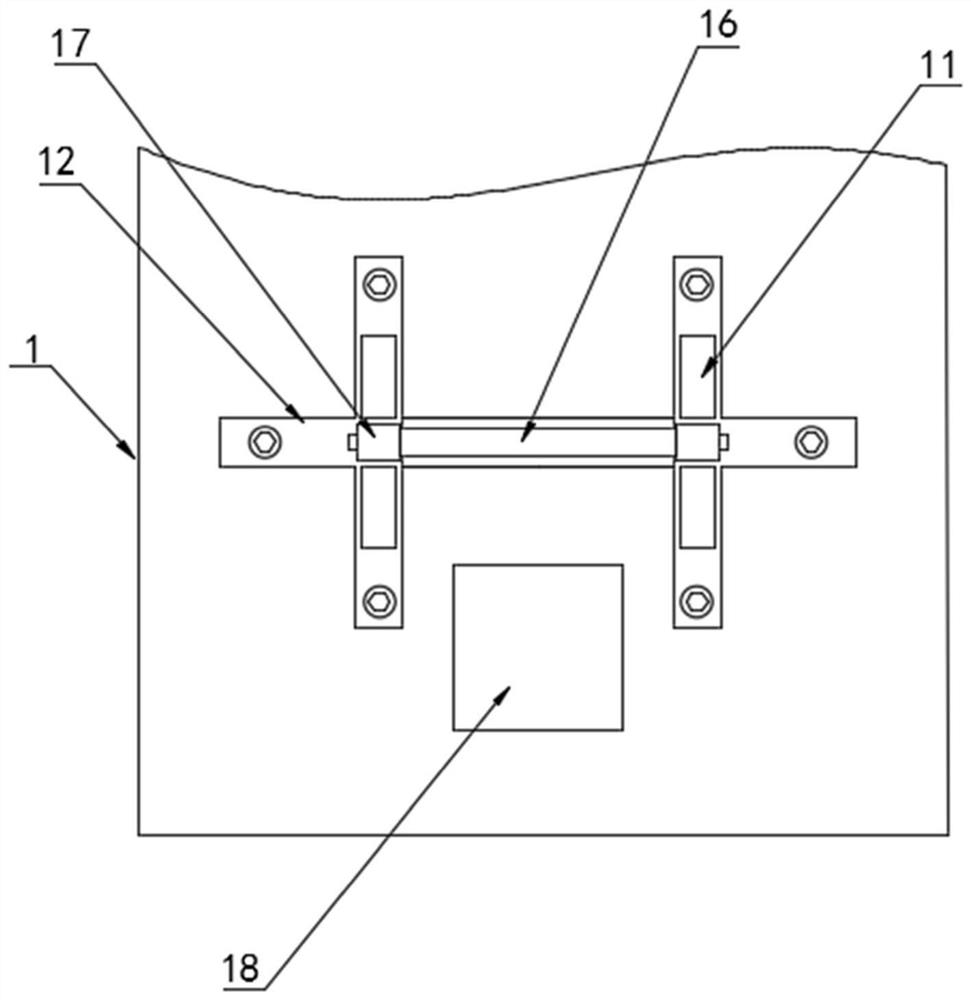

[0027] Refer to the attached Figure 1-5 In this embodiment, a chassis supporting structure of a hoisting machine and a crane include a chassis 1 and a boom 2, and first hydraulic rods 4 are fixedly installed at both ends of the chassis 1, and the bottom of one end of the first hydraulic rod 4 is fixed The second hydraulic rod 3 is installed, and the top of the left end of the chassis 1 is fixedly installed with a landing support 6, and one end of the landing support 6 is provided with a chute 23, and the landing support 6 is slidably connected to the landing support plate 21, and the landing support A buffer spring 22 is fixedly installed at the bottom of the plate 21, the bottom of the buffer spring 22 is fixedly installed on the top of the landing support seat 6, the top of the chassis 1 is fixedly connected to the support plate 10 by bolts, and the top of the support plate 10 is fixedly connected to the support seat One 9, the support seat one 9 is movably connected to the...

Embodiment 2

[0034] Refer to the attached Figure 6 , the difference from Embodiment 1 is that: the top of the landing support 6 is provided with a placement groove 25, and a buffer block 24 is arranged in the placement groove 25, and the buffer block 24 is made of fluorine rubber;

[0035] The specific implementation scenarios are:

[0036] Compared with Embodiment 1, when using the present invention, the extension of the first hydraulic rod 4 drives the second hydraulic rod 3 to expand outward, and the second hydraulic rod 3 is extended to touch the ground, so as to increase the contact point between the chassis 1 and the ground The formed area enhances the stability of the chassis 1. When the object needs to be hoisted, the first lifting hydraulic rod 8 is extended, and the left end arm sleeve 7 is pushed up, so that the left end of the boom 2 is raised, and the second lifting hydraulic pressure The rod 14 shrinks and pulls the right end arm cover 7 downward, and the right end arm cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com