Aluminum oxide and preparation method and application thereof

A technology of alumina and aluminum alkoxide, which is applied in the fields of alumina/hydroxide preparation, chemical instruments and methods, and inorganic chemistry, and can solve problems such as low crystallinity and purity of alumina, inability to realize continuous production, and complicated preparation process , to achieve the effect of low production cost, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

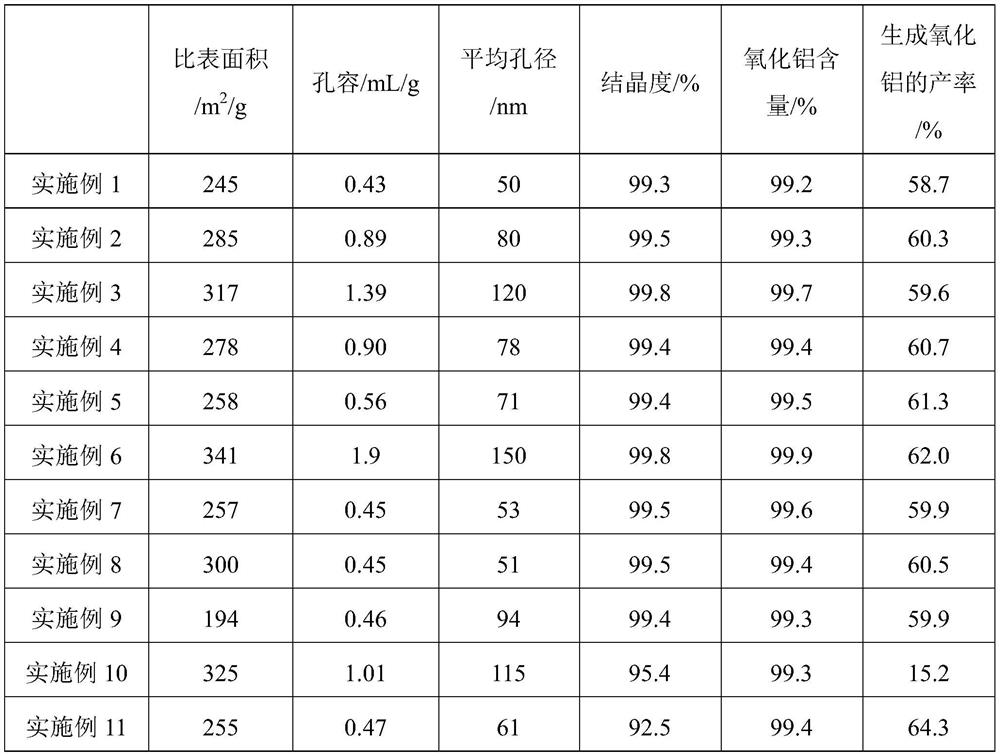

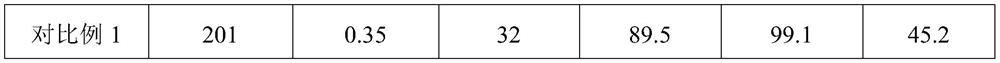

Examples

Embodiment 1

[0079] Add 100g of isopropanol, 10g of aluminum powder with a purity of 99.9% and 0.1g of aluminum chloride into the reactor, raise the reaction temperature to 95°C, and continue the reaction for 8 hours to obtain the required isopropanol and isopropanol by vacuum distillation aluminum.

[0080]Add 100g of pure water to a 15L reactor with stirring, start stirring and control the stirring rate to 100rad / min, then add the aluminum isopropoxide dropwise at a rate of 10g / min, raise the hydrolysis temperature to 80°C, and continue hydrolysis Reaction 5min; After the completion of the reaction, control the rate of addition of aluminum isopropoxide to 10g / min, and control the rate of addition of isopropanol-water mixed solution to 151g / min. In this isopropanol-water mixed solution, Virahol and water The mass ratio is 1:9, and the concentration of pseudo-boehmite in the control reactor is 0.14g / ml; the overflow port of the reactor is opened, and it is controlled to flow into the 10L a...

Embodiment 2

[0083] Add 500g of isopropanol, 100g of aluminum powder with a purity of 99.9% and 0.5g of aluminum chloride into the reactor, raise the reaction temperature to 95°C, and continue the reaction for 8 hours to obtain the required isopropanol and isopropanol by vacuum distillation aluminum.

[0084] Add 50g of pure water to a 10L reactor with stirring, start stirring and control the stirring rate to 300rad / min, then add the aluminum isopropoxide dropwise at a rate of 5g / min, increase the hydrolysis temperature to 100°C, and continue hydrolysis Reaction 10min; After the completion of the reaction, control the rate of addition of aluminum isopropoxide to 5g / min, control the rate of addition of isopropanol aqueous solution to 86g / min, and the mass ratio of isopropanol and water in this isopropanol aqueous solution is 1:1, control the concentration of pseudo-boehmite in the reactor to 0.23g / ml; open the overflow port of the reactor, and control it to flow into the 10L aging kettle at...

Embodiment 3

[0087] Add 200g of isopropanol, 40g of aluminum powder with a purity of 99.9% and 0.5g of aluminum chloride into the reactor, raise the reaction temperature to 95°C, and continue the reaction for 8 hours to obtain the required isopropanol and isopropanol by vacuum distillation aluminum.

[0088] Add 200g of pure water to a 20L reactor with stirring, start stirring and control the stirring rate to 300rad / min, then add the aluminum isopropoxide dropwise at a rate of 20g / min, raise the hydrolysis temperature to 85°C, and continue hydrolysis Reaction 15min; After the completion of the reaction, control the rate of addition of aluminum isopropoxide to 20g / min, control the rate of addition of isopropanol aqueous solution to 400g / min, and the mass ratio of isopropanol and water in this isopropanol aqueous solution is 9:1, control the concentration of pseudo-boehmite in the reactor to be 0.29g / ml; open the overflow of the reactor, and control it to flow into the 10L aging kettle at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com