Heat supply wear-resistant ball valve

A wear-resistant, ball valve technology, used in lift valves, valve details, valve devices, etc., can solve problems such as poor accuracy, aggravated rubber sealing ring wear, valve seat sealing ring damage, etc., to reduce wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

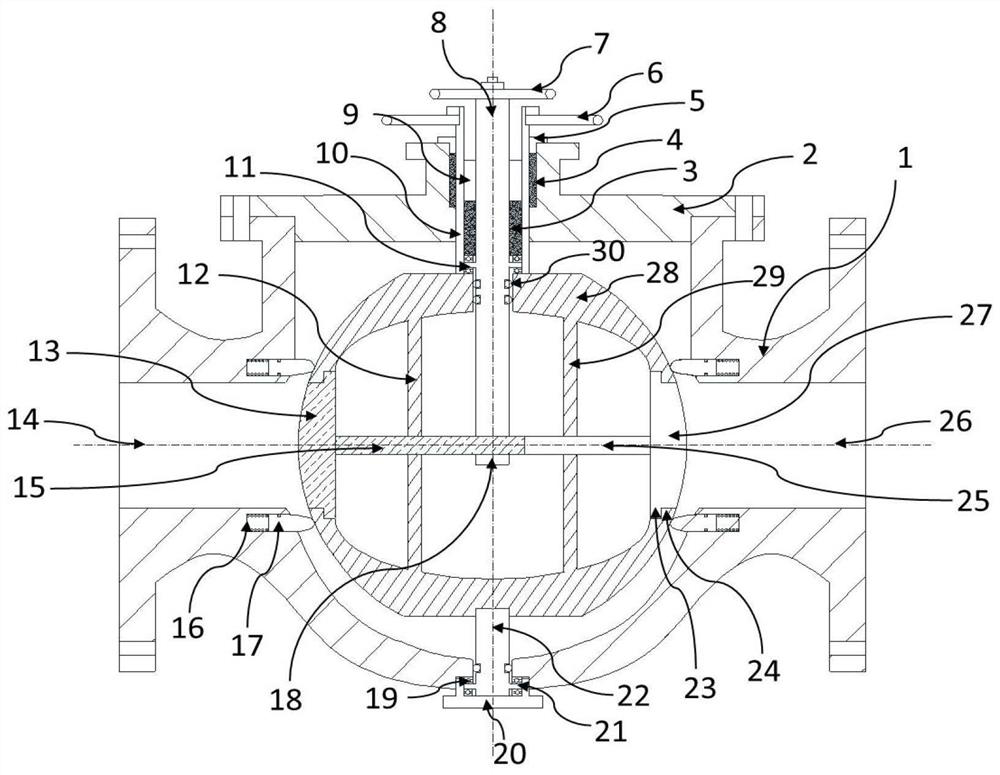

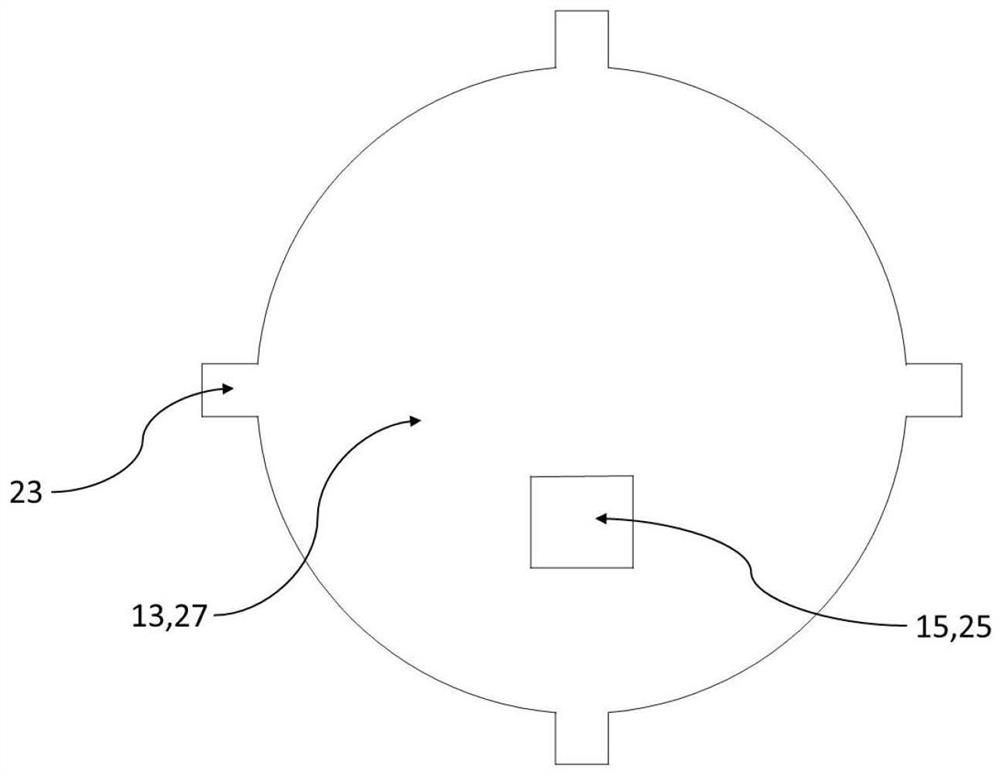

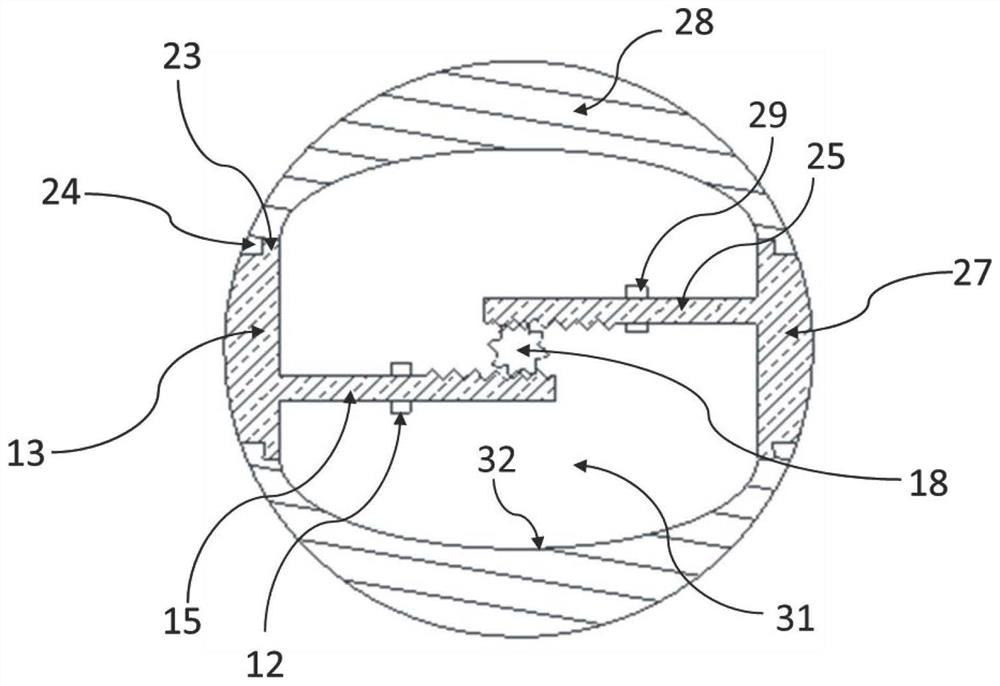

[0022] Such as figure 1 In the shown heat-supply wear-resistant ball valve, the valve body 1 has an inlet passage 14, an outlet passage 26, an upper opening, and a cavity between the inlet passage 14 and the outlet passage 26, and internal components such as a ball 28 and a valve seat can be Put into the middle chamber of the valve body 1 through the upper opening; the valve cover 2 is fixedly arranged on the top of the valve body 1 for closing the upper opening; the ball 28 is arranged in the middle chamber, and the inside of the ball 28 is provided with a ball inner chamber 31, and the ball 28 has The first through hole that communicates with the inlet channel 14 and the inner cavity of the ball 31 and the second through hole that communicates with the outlet channel 26 and the inner cavity 31 of the ball; the outer valve stem 10 is a hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com