Intelligent operation and maintenance system for platform door

An operation and maintenance system and platform door technology, applied in the field of platform doors, can solve the problems of transmission and transmission jams, insufficient processing capacity, and maintenance of large-scale manpower equipment, and achieve the effect of avoiding data transmission interruption and ensuring authenticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

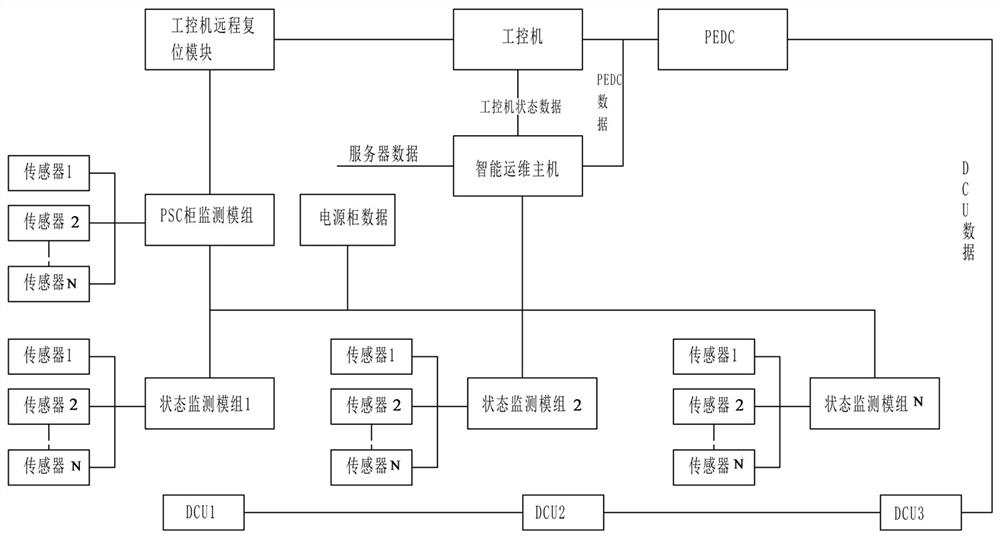

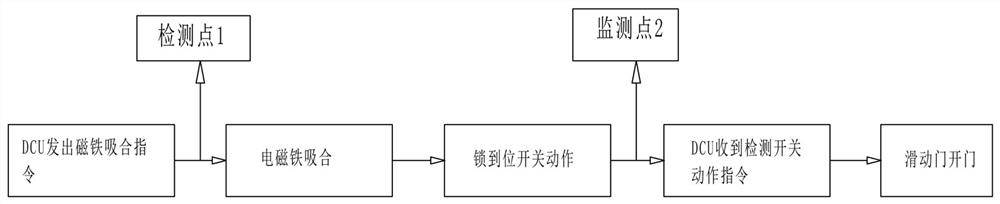

[0030] This embodiment provides an intelligent operation and maintenance system for platform doors, such as figure 1 and figure 2 As shown, it includes a main control cabinet PSC, a door control unit DCU, a logic control unit PEDC, an industrial computer, an integrated monitoring system, and a power supply cabinet; the door control unit DCU and the main control cabinet PSC are equipped with a state monitoring module ; The logic control unit PEDC, the door control unit DCU, the main control cabinet PSC, and the power supply cabinet are also connected to the server through an intelligent operation and maintenance host.

[0031] The intelligent operation and maintenance host directly communicates with the logic control unit PEDC through the first data communication interface, and reads the platform door system operation data output by the logic control unit PEDC; the intelligent operation and maintenance host communicates with the industrial computer through the second data comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com