Vacuum oil injection structure of large oil-immersed transformer and oil conservator and working method of vacuum oil injection structure

An oil-immersed transformer and oil-filling structure technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of high partial discharge of the transformer, inability to fill part of the oil conservator with vacuum oil, insufficient degassing of the transformer oil, etc., so as to prevent the suction of the vacuum pump. , to ensure the effect of work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

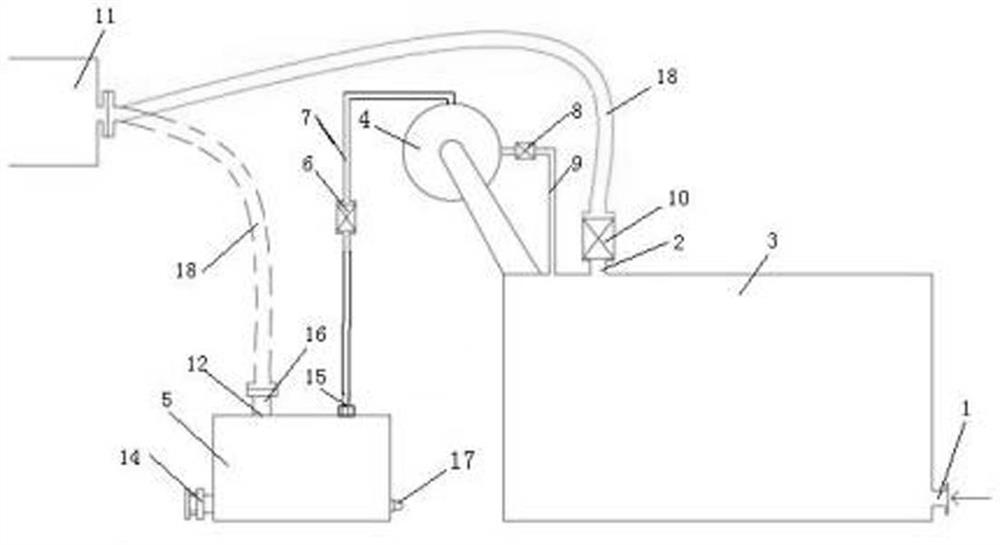

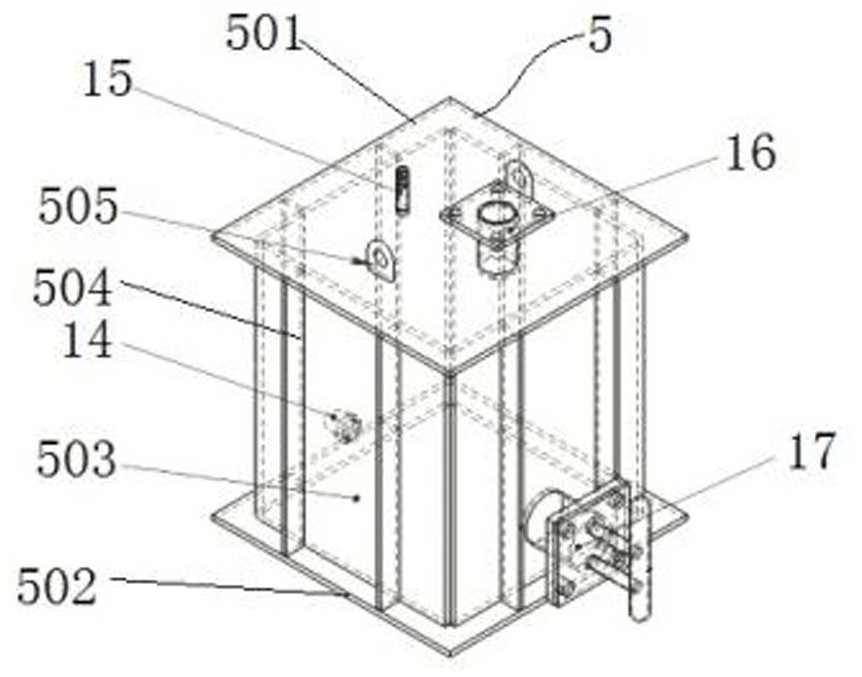

[0016] The vacuum oil filling structure of the large oil-immersed transformer and oil conservator of the present invention comprises a large oil-immersed transformer 3 having an oil inlet 1 and a first negative pressure port 2, and an oil conservator is arranged above the large oil-immersed transformer 3 4. The large oil-immersed transformer 3 is provided with a transitional oil tank 5 for vacuum oil filling, and a third communicating pipeline 7 with a third butterfly valve 6 is connected between the transitional oil tank 5 for vacuum oil filling and the oil conservator 4. The oil conservator 4 The second communication pipeline 9 with the second disc valve 8 is connected with the large oil-immersed transformer 3, the first negative pressure port 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com