Integrated lower bottom plate of anti-extrusion battery lower box body, and preparation method thereof

A technology of anti-extrusion and bottom plate, which is applied in the direction of secondary batteries, electrochemical generators, battery pack components, etc., can solve the problems of low space utilization, unintegrated battery box and water cooling structure, and heavy battery system weight and other issues, to achieve excellent structural strength and rigidity, to meet the effect of light weight and lower requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with solid and embodiment the present invention will be further described.

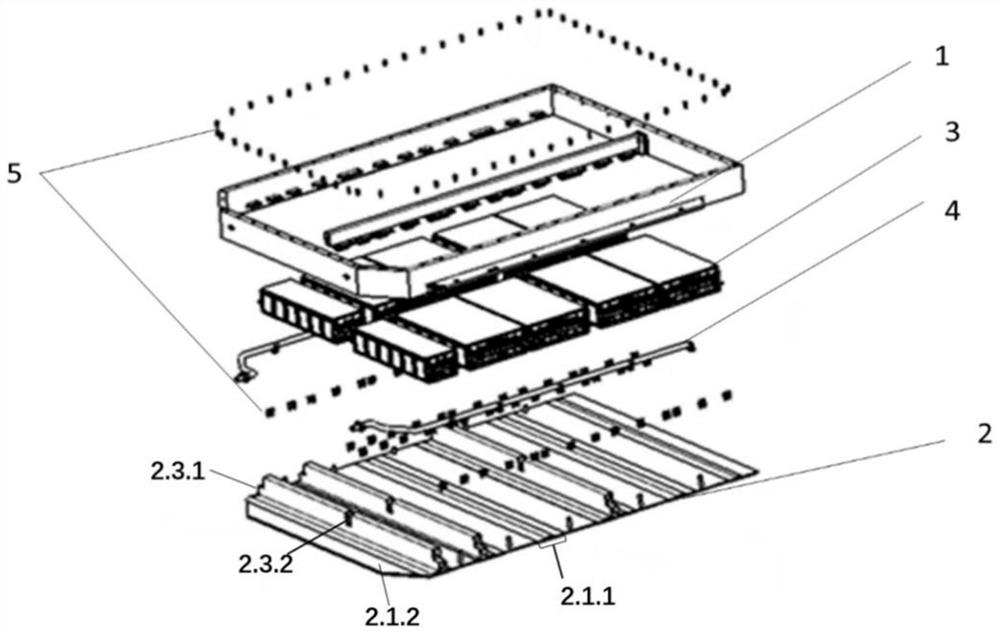

[0032] Such as figure 1 As shown, an anti-extrusion battery lower box includes a frame beam assembly 1, a lower bottom plate 2, a 590 large module 3 with a lug end plate, a pipeline 4 composed of a tee / hose / pipe joint and riveted Standard parts 5.

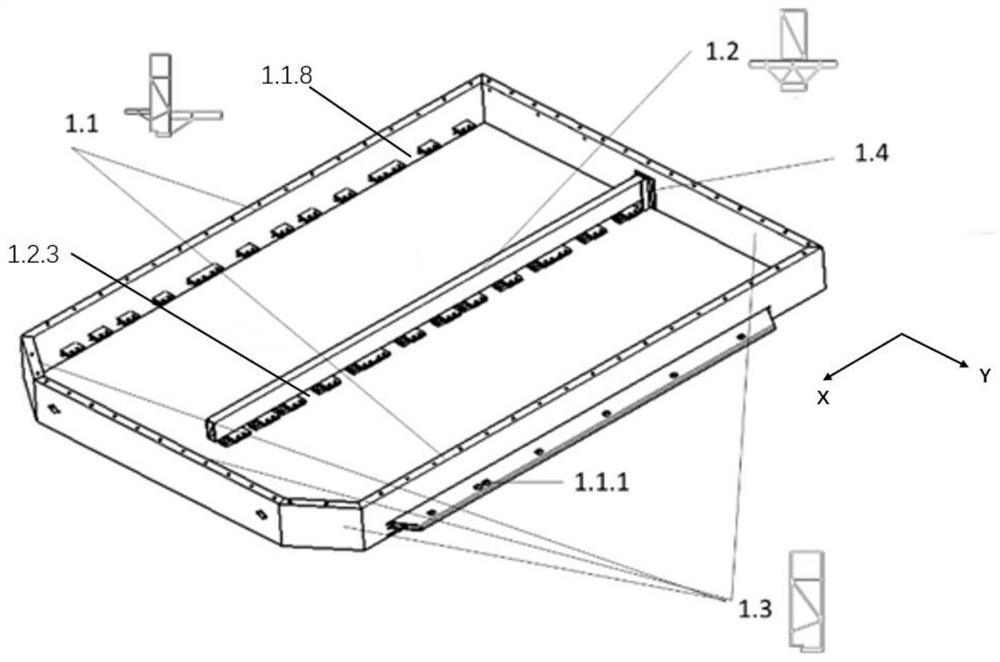

[0033] Such as figure 1 and figure 2 As shown, the frame beam assembly 1 includes left and right load-bearing side beams 1.1, front and rear side beams and corner side beams 1.3, and a load-bearing middle beam 1.2. The left and right load-bearing side beams 1.1, the front and rear side beams and the bottom of the corner side beams 1.3 are all provided with approximately square grooves, and the two ends of the floor beam 2.3 are provided with bosses 2.3.1 overlapping with the approximately square grooves; The U-shaped opening 2.3.2 overlapping with the load-bearing center beam 1.2.

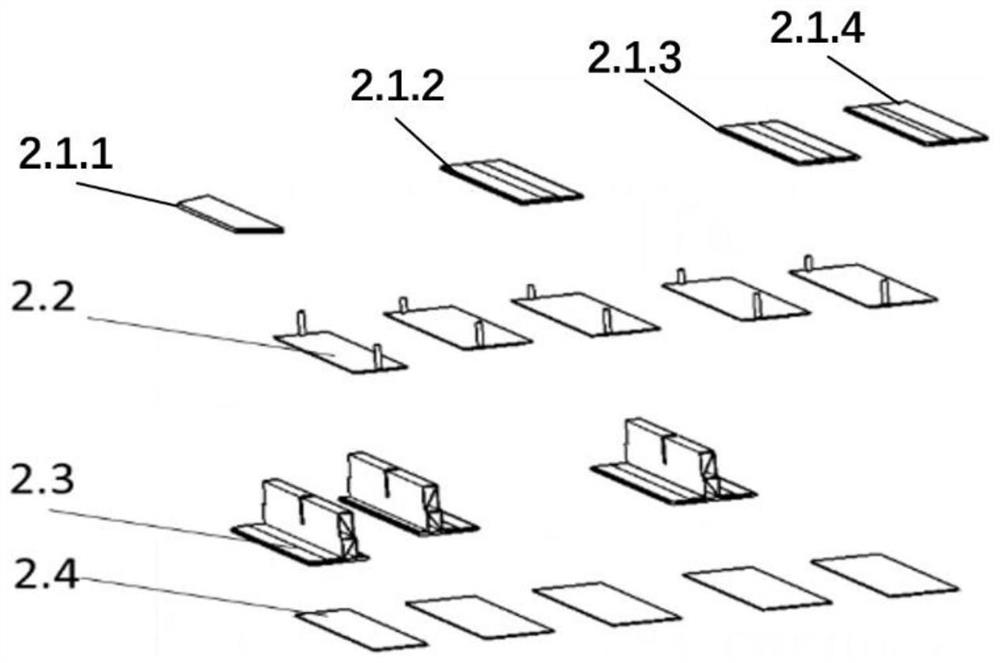

[0034] image 3 As shown, the lower bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com