Sticky microstructure AGM (Absorbed Glass Mat) clapboard

A microstructure and partition technology, applied in structural parts, electrical components, circuits, etc., can solve the problems of polymer colloids such as water resistance, poor acid resistance, and unstable partition structure, so as to improve oxygen recombination efficiency and chemical stability , Good assembly pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

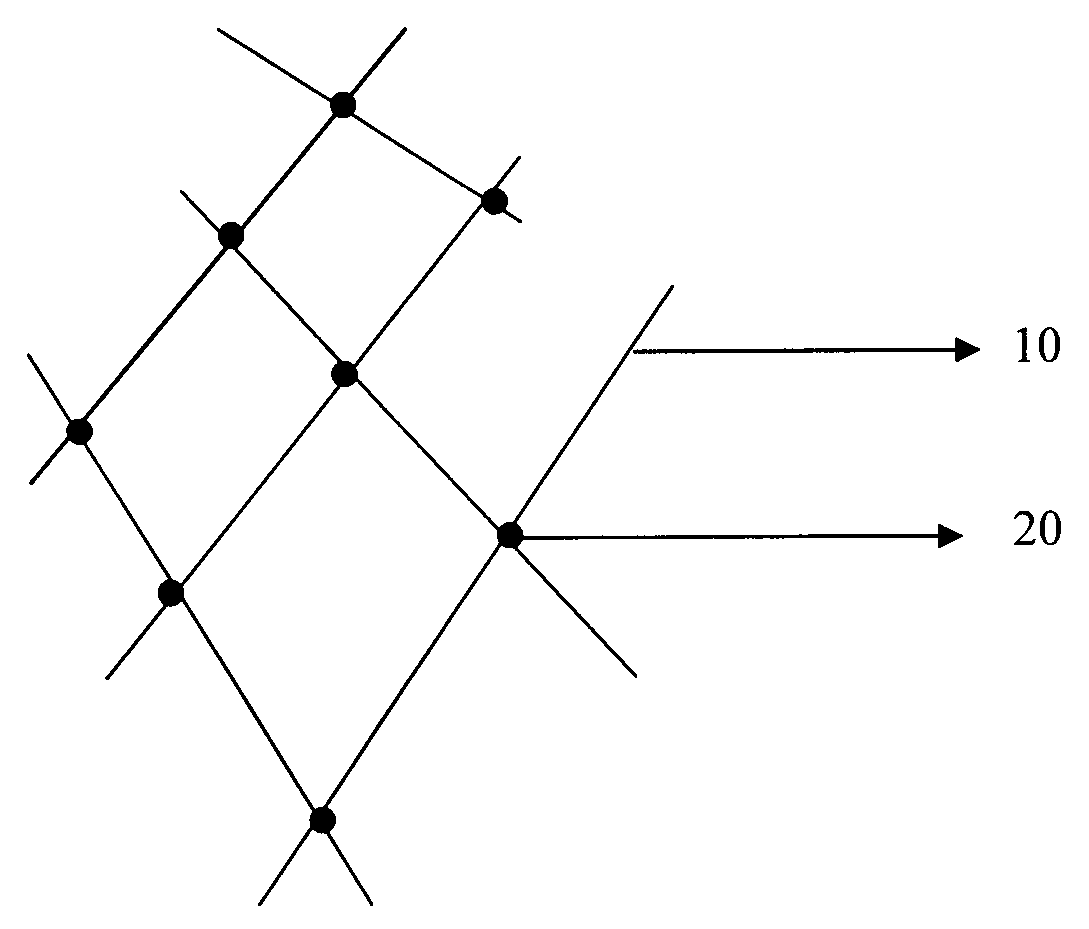

[0025] refer to figure 1 , an AGM separator with a cohesive microstructure, characterized in that there are binder particles at the overlap between glass fibers and glass fibers in the AGM separator. The weight percentage of the glass fiber is 90%, and the weight percentage of the fine-diameter glass fiber with an average diameter of 0.6 μm is 100%. The binder particles are polyester viscose with a weight percentage of 10% and an average particle size of 14 μm. The breaking strength of the two fibers bonded by the binder particles is 4500 MPa.

Embodiment 2

[0027] refer to figure 1 , an AGM separator with a cohesive microstructure, characterized in that there are binder particles at the overlap between glass fibers and glass fibers in the AGM separator. The weight percentage of the glass fiber is 95%, wherein the weight percentage of the thin glass fiber with an average diameter of 0.9 μm is 80%, and the weight percentage of the medium and large diameter glass fiber with an average diameter of 5 μm is 20%. The binder particles are polypropylene viscose with a weight percentage of 5% and an average particle size of 9 μm. The breaking strength of the two fibers bonded by the binder particles is 3500 MPa.

Embodiment 3

[0029] refer to figure 1 , an AGM separator with a cohesive microstructure, characterized in that there are binder particles at the overlap between glass fibers and glass fibers in the AGM separator. The weight percentage of the glass fibers is 99%, wherein the weight percentage of the thin glass fibers with an average diameter of 1.1 μm is 65%, and the weight percentage of the medium and large diameter glass fibers with an average diameter of 8 μm is 35%. The binder particles are polyethylene viscose with a weight percentage of 1% and an average particle size of 4 μm. The breaking strength of the two fibers bonded by the binder particles is 2500MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com