Battery cell end face forming device

A molding device and molding tooling technology are applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, etc. to avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above and other objects, features and advantages of the present invention more apparent, the following specifically cites the embodiments of the present invention, together with the accompanying drawings, for a detailed description as follows.

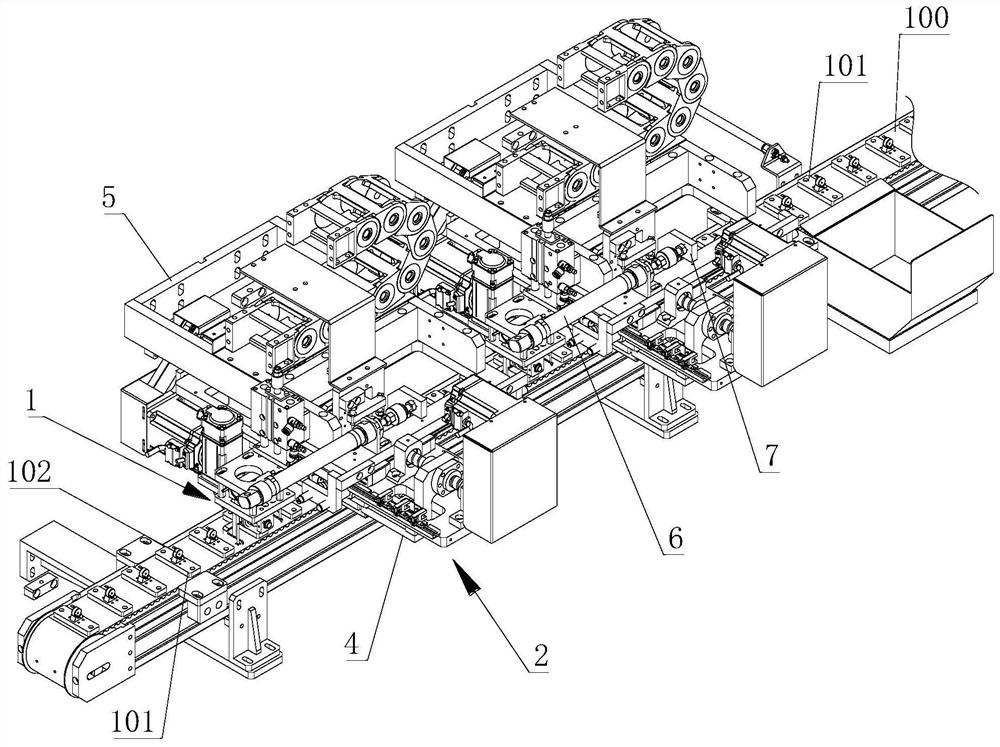

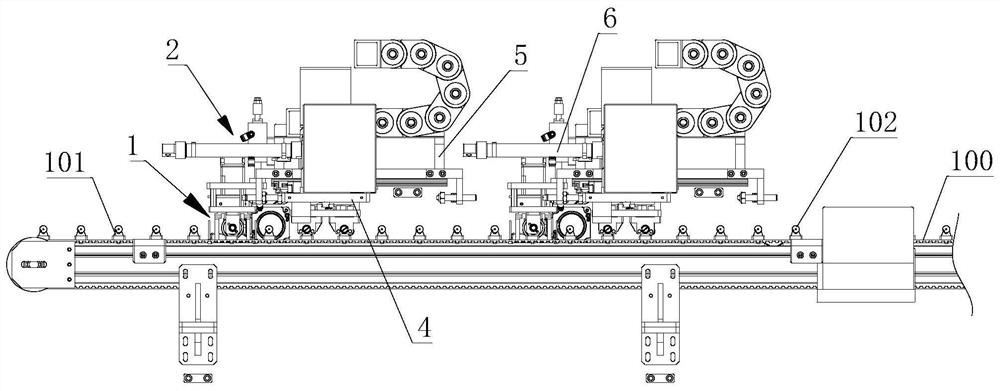

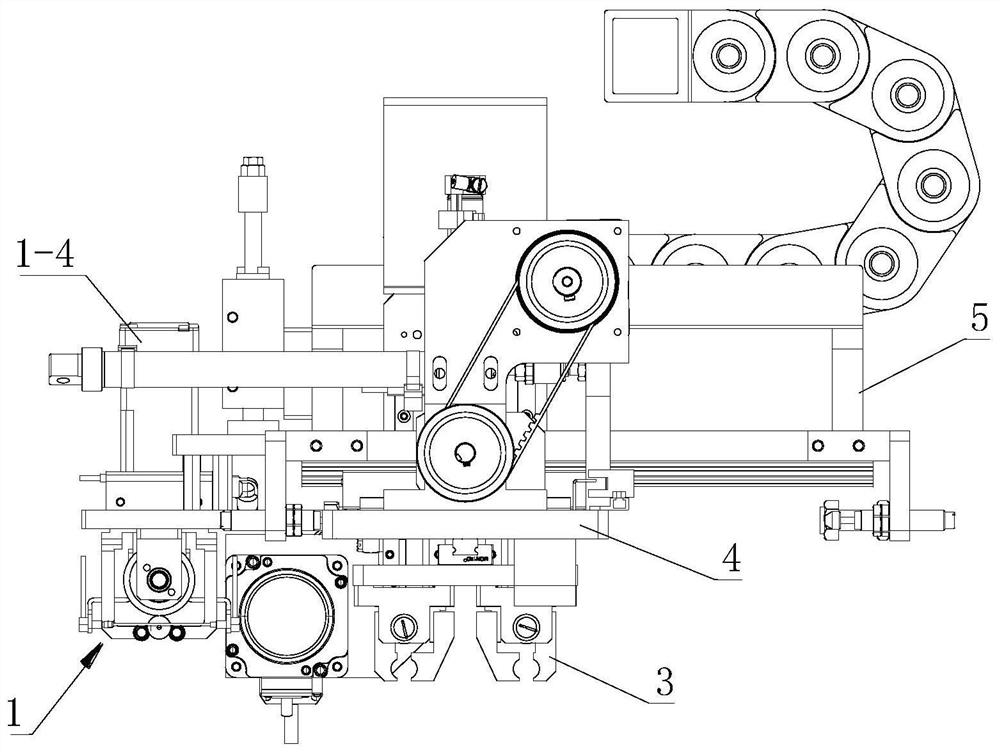

[0035] Such as figure 1 and figure 2 As shown, the battery end face forming device of this embodiment is arranged after the battery winding and blanking station, and the wound battery is transported by the battery conveyor belt 100 (cutting) after completing the previous process (center ironing hole). Conveyor line) is transported backward, and the battery cell 102 is placed on the battery cell carrier 101 of the battery cell conveyor belt 100, and moves through the battery cell end face forming device as the battery cell conveyor belt 100 moves. One or more electric core end face forming devices can be provided to improve the efficiency of electric core end face forming.

[0036] combine Figure 1 to Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com