Ceramic dielectric waveguide filter with transmission zero point

A waveguide filter and transmission zero-point technology, applied in the field of filters, can solve the problems of difficult metallization, difficult to realize, and difficult to process the transmission zero-point structure, so as to achieve the effect of simple processing and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

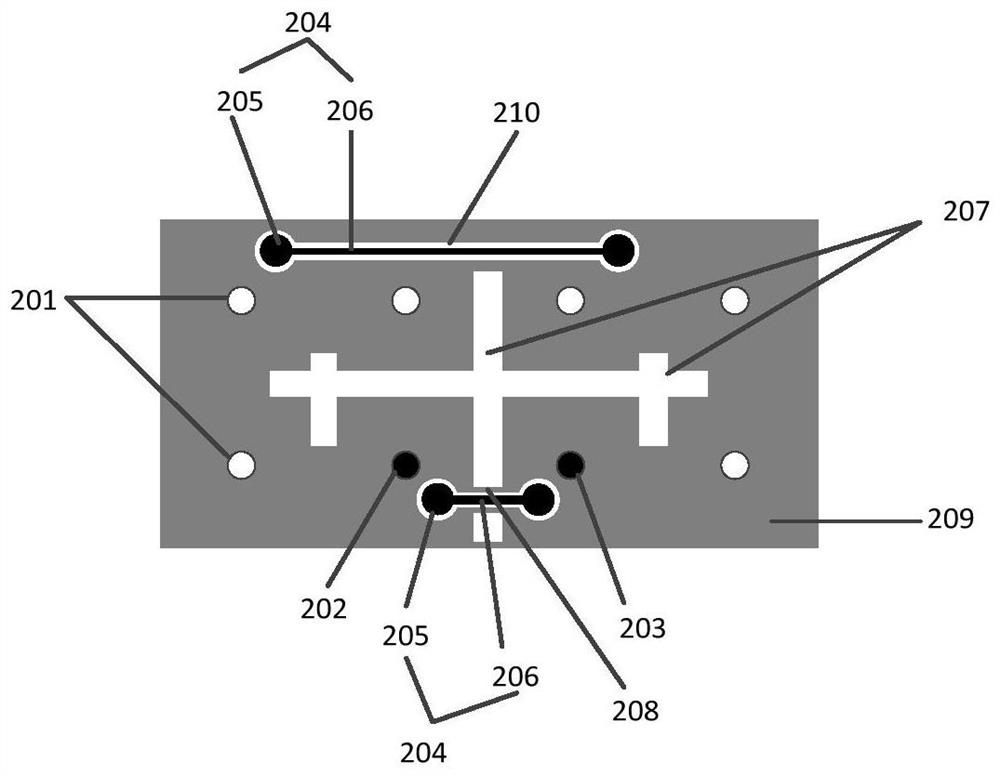

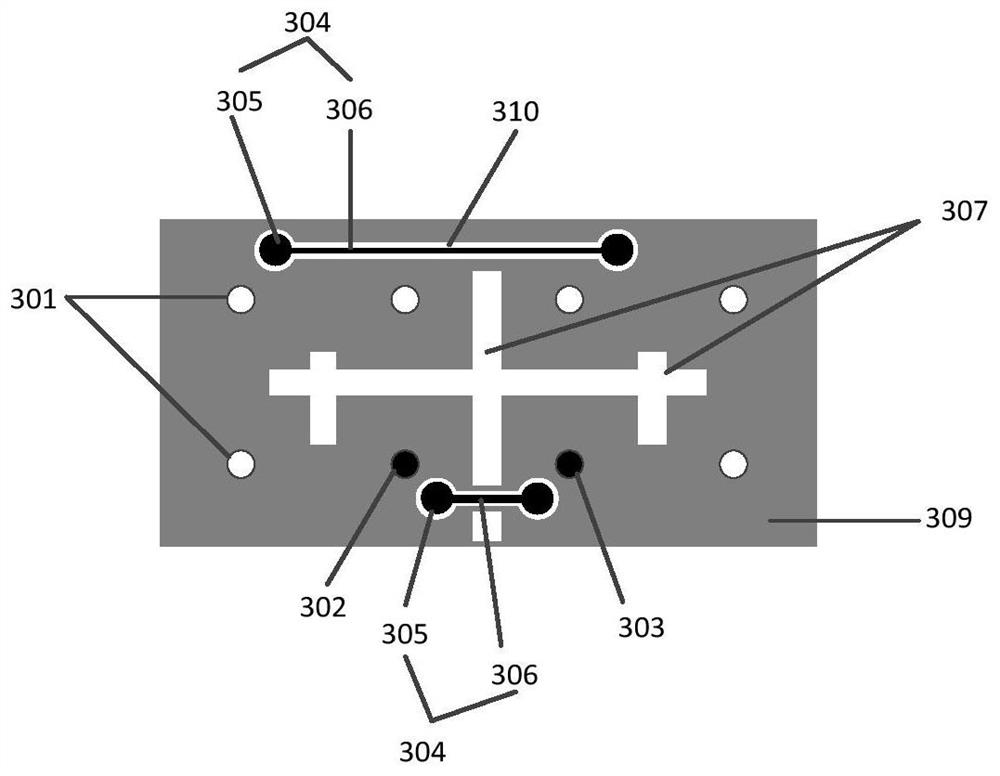

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

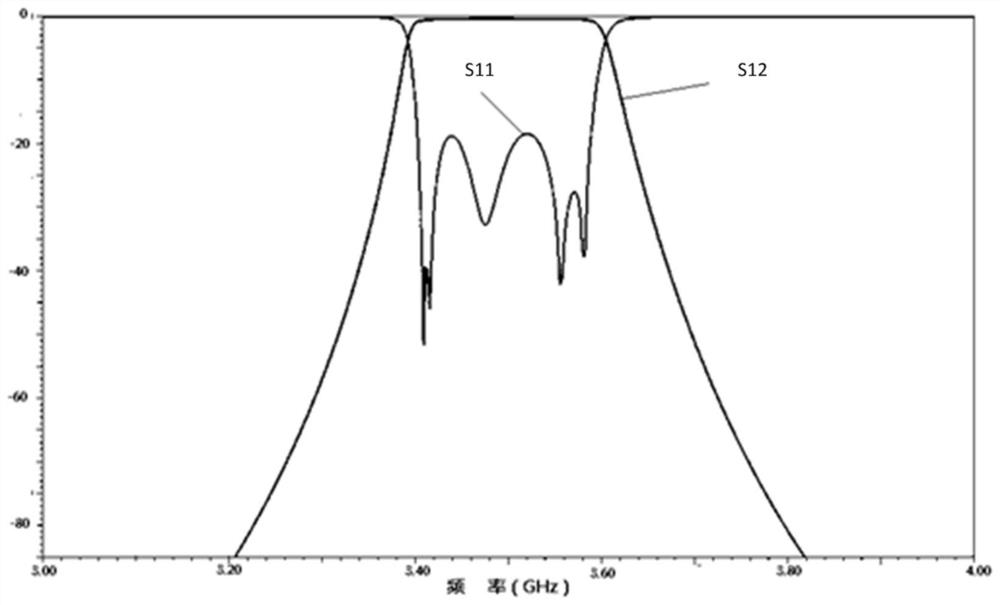

[0033] Ceramic dielectric waveguide filter is a filter designed and manufactured by utilizing the characteristics of low loss, high dielectric constant, frequency temperature coefficient and thermal expansion coefficient of dielectric ceramic materials, and can withstand high power. The ceramic dielectric waveguide filter is composed of several elongated resonators vertically multi-level series or parallel trapezoidal lines, and each resonator can also be called a resonant cavity. The ceramic dielectric waveguide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com