Lower tool with friction reduction device

A tool and friction coefficient technology, applied in the field of lower tools, can solve problems such as heavy technical work and increased production costs, and achieve the effects of improving safety, long use intervals, and avoiding jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] First of all, it should be noted that in the different embodiments described, the same parts have the same reference numerals and / or the same component names, wherein the disclosure contained in the entire specification can be similarly interchanged to have the same components. on the same parts with the same reference numerals and / or the same component names. Furthermore, selected position descriptions in the description (eg at top, at bottom, on the side) refer to the directly described and depicted view, and in the event of a change of position these position descriptions should be similarly replaced by the new position.

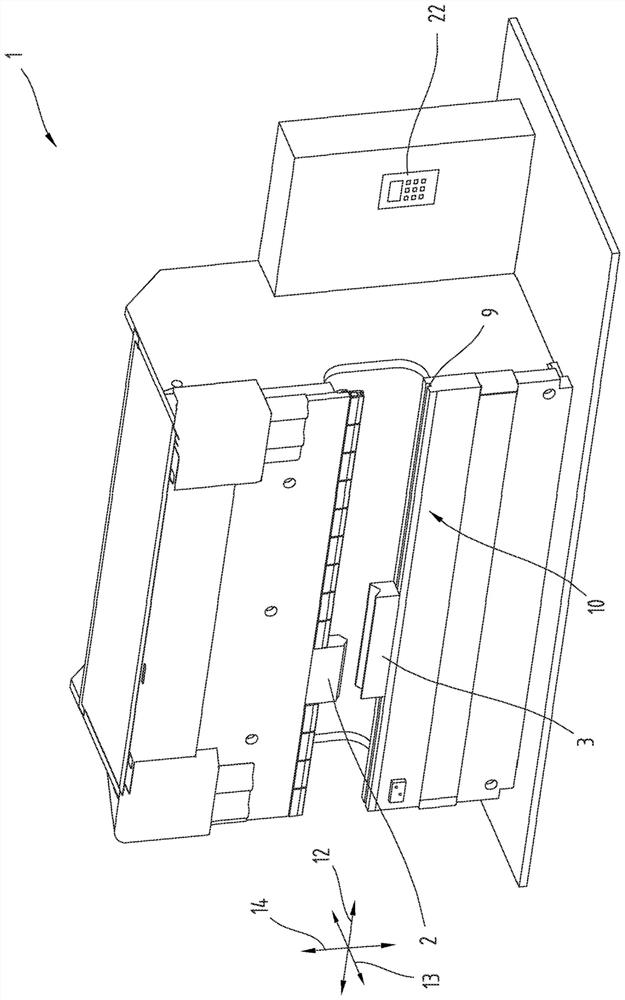

[0046] exist figure 1 , a schematic representation of a bending machine 1 with a system controller 22 , an upper tool 2 and a lower tool 3 arranged on a tool holder 10 is shown. The schematic illustration also shows a substantially vertical load direction 14 and a longitudinal direction 12 along which the lower tool 3 is displaceable in the guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com