Weeding machine with troubleshooting device

A weeding machine and a technology for installing shells, which are applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of affecting the performance and service life of the equipment, time-consuming and labor-intensive cleaning, and low practicability, so as to ensure the service life. The effect of high efficiency and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

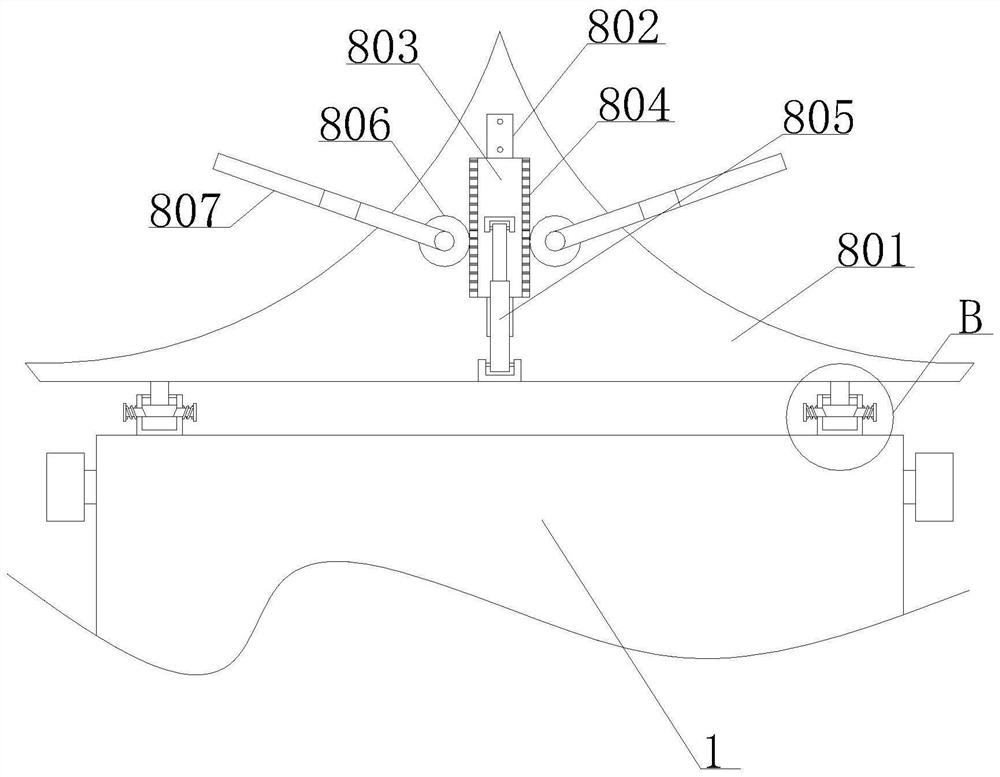

[0038] Embodiment 1, the tail end of the block 801 is fixedly installed with a fixed rod 808, the left end of the vehicle body frame 1 is fixedly installed with a limit block 809, the inside of the limit block 809 is movably connected with a block 810, and the surface of the block 810 is sleeved There is a clamping spring 811. When the stopper 801 is subjected to an impact force, the fixed rod 808 squeezes the clamping block 810 to move to both sides. During the movement of the clamping block 810, the impact force is absorbed by the clamping spring 811 and converted into a clamping spring 811 mechanical energy, so that the equipment body has better self-protection ability.

Embodiment 2

[0039] In Embodiment 2, the cover plate 1003 is fixedly installed on the surface of the installation shell 1002, which can effectively prevent the interference of external factors during operation, thereby ensuring that the cut grass can be smoothly transported to the inside of the collection box 901.

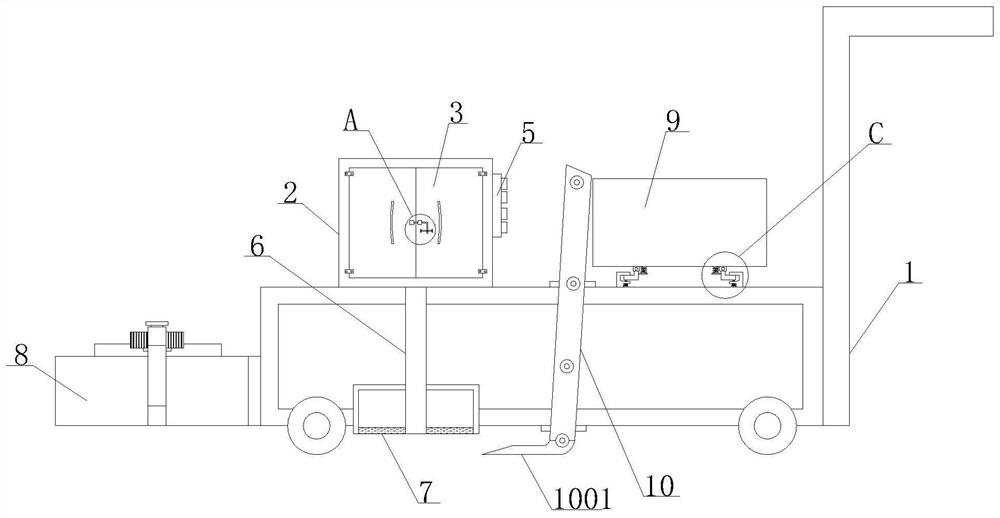

[0040] Working principle: Push the car body frame 1, open the blade 7 through the control button 5 to carry out weeding operations, because the collection head 1001 is close to the ground, the cut grass can be collected, and then transported to the collection by the conveyor belt 1005 and the vertical plate 1006 Inside of the box 901, when the collection box 901 is full, pull the push rod 906, then turn the clamp arm 902 to make it break away from the inside of the fixed block 905, then the collection box 901 can be taken out, and the grass in the inside can be poured out, and then Pull the ejector rod 906 again and then snap the clamp arm 902 into the inside of the fixed block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com