Automatic silicon carbide micro-powder separating and grinding device

A silicon carbide micropowder and grinding device technology, applied in grain processing and other directions, can solve the problems of wasting time and working pressure, and achieve the effects of easy use, high work efficiency, rapid grinding and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

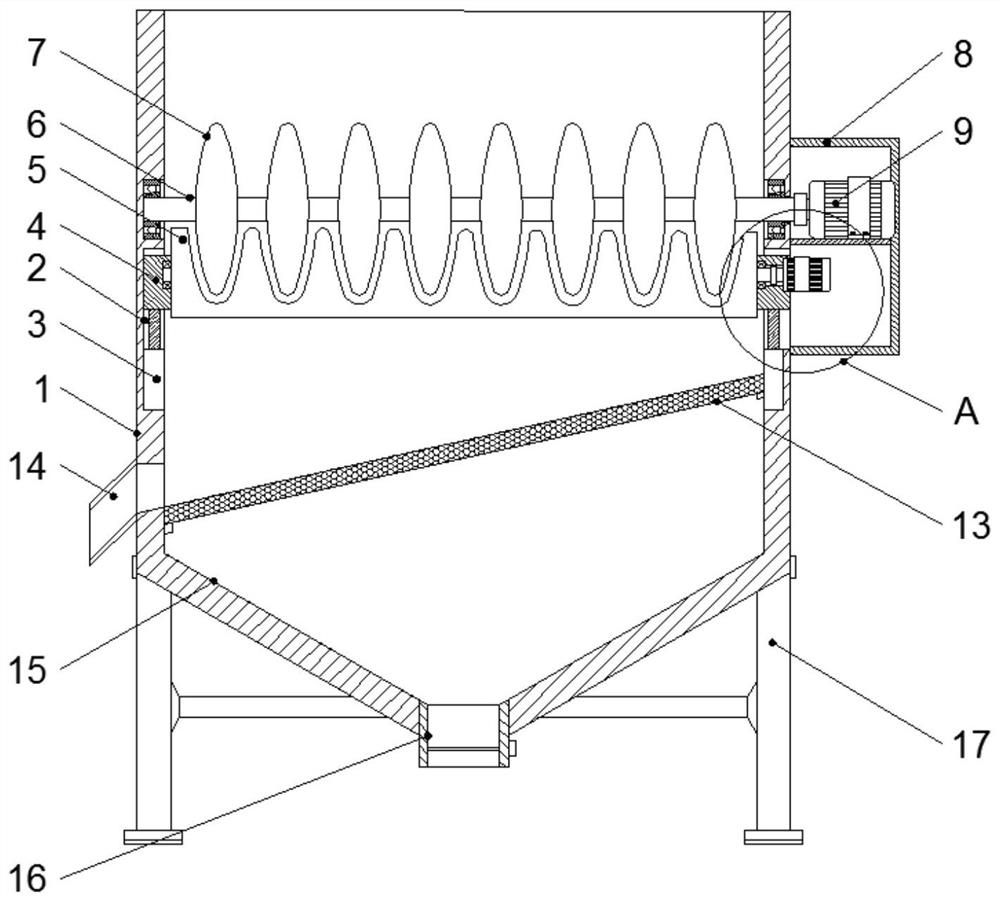

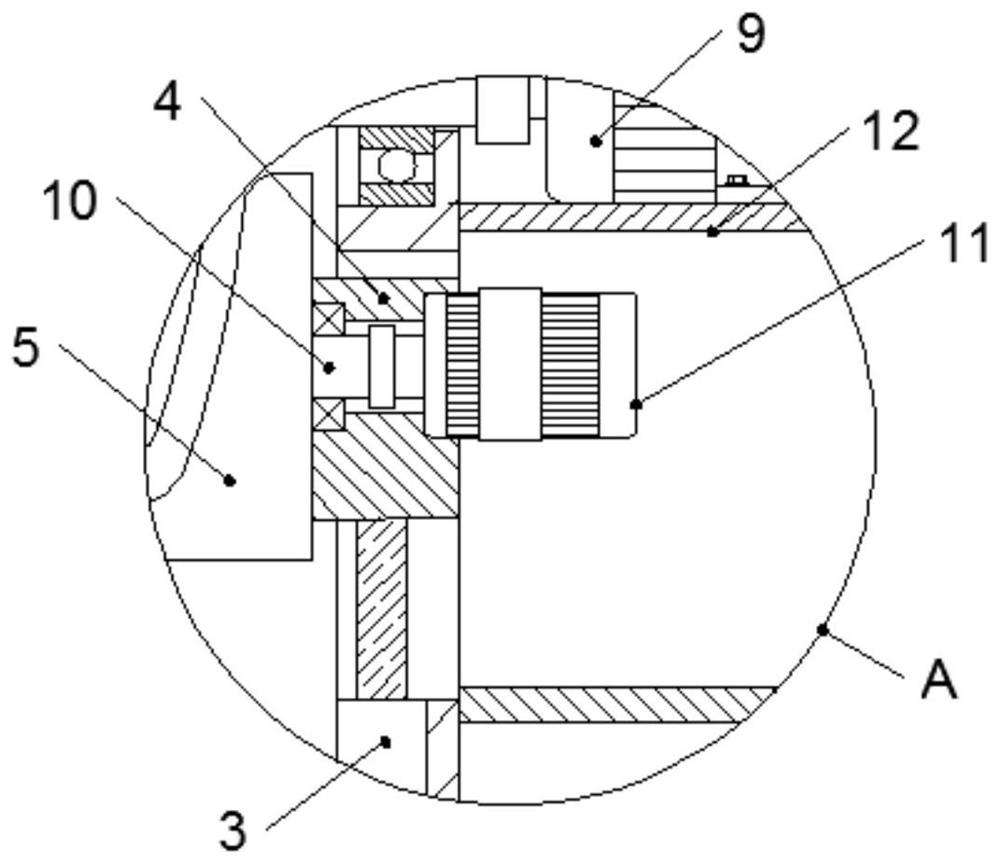

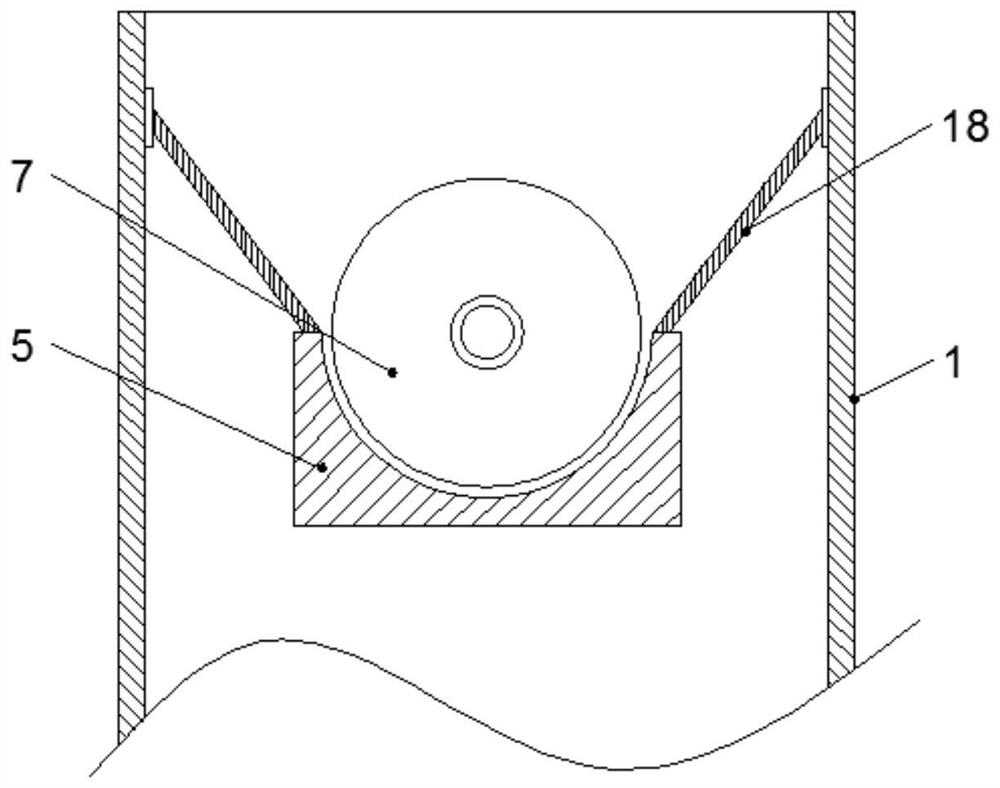

[0025] Example: such as Figure 1-4 As shown, an automatic silicon carbide powder separation and grinding device of the present invention includes a main box body 1, and installation grooves 2 are symmetrically arranged on both sides of the interior of the main box body 1, and hydraulic pressure is fixedly installed inside the installation groove 2. Cylinder 3, the top of the hydraulic cylinder 3 is provided with a piston rod, and the top of the piston rod is fixedly connected with a fixed block 4, the inside of the main box 1 is provided with a grinding groove 5 between the two fixed blocks 4, And the grinding tank 5 is fixedly connected with the fixed shaft 10 at the two ends close to the fixed block 4, and is fixedly connected with the fixed block 4 through the fixed shaft 10, and the inside of the main box 1 is fixed and installed horizontally near the top of the grinding tank 5 There is a rotating shaft 6, and a plurality of grinding discs 7 are fixedly installed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com