Potato thickness adjustable slicing machine

An adjustable, potato technology, applied in metal processing and other directions, can solve the problems of substandard quality, uneven cutting, low efficiency, etc., to achieve the effect of strong accommodation and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

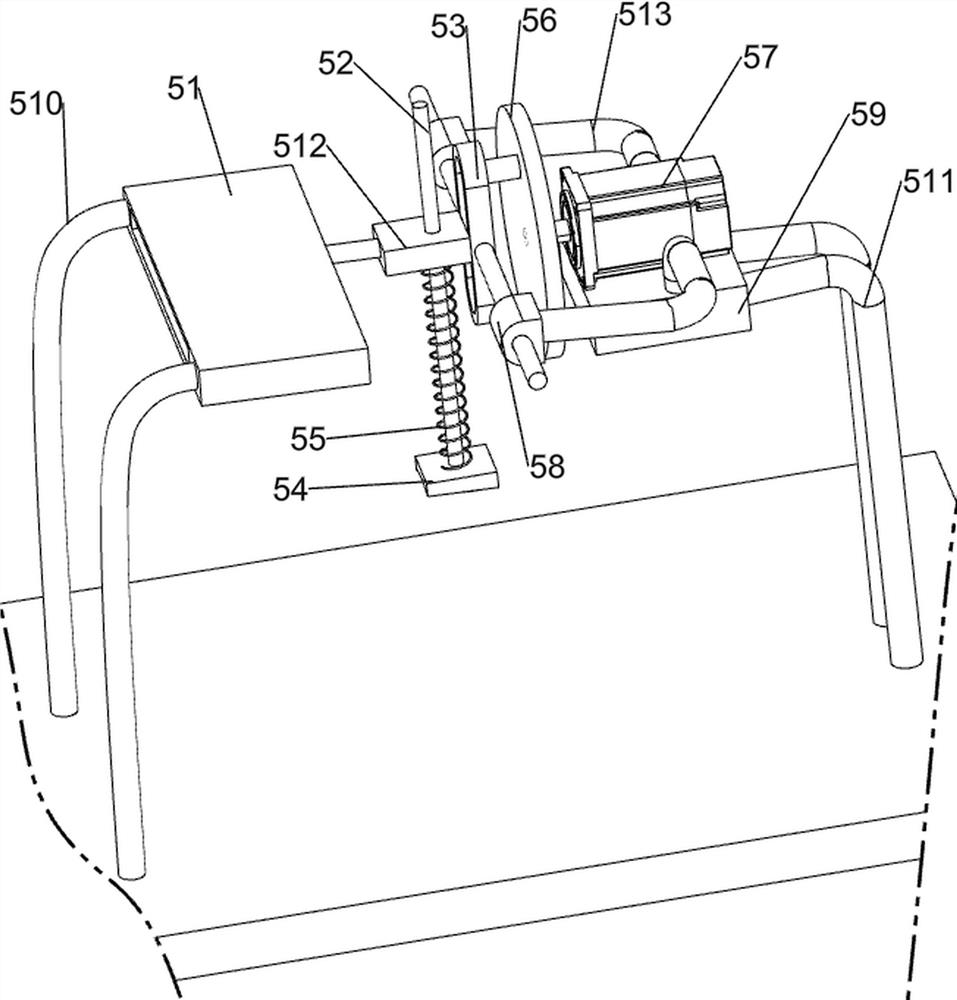

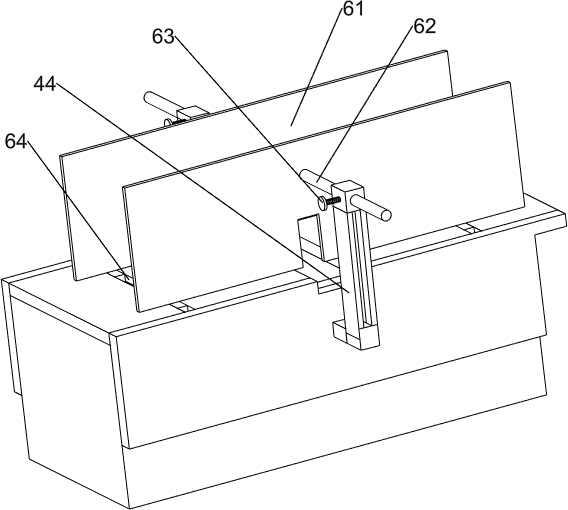

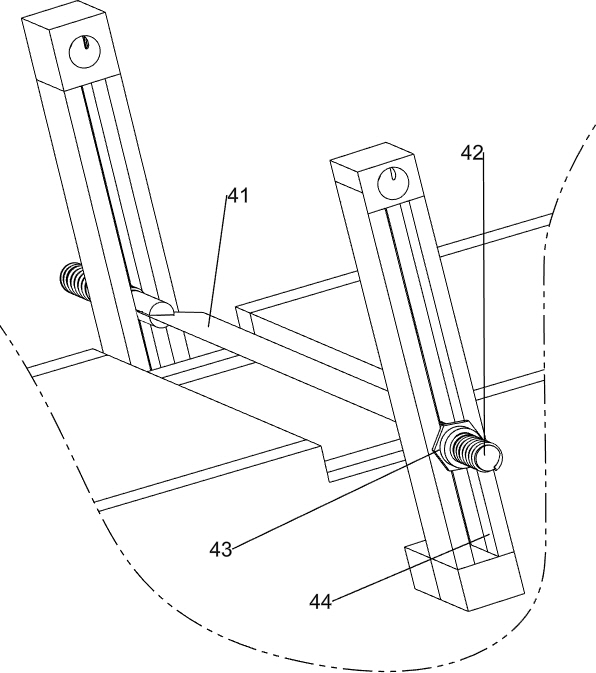

[0021] A potato slicer with adjustable thickness, such as figure 1 As shown, it includes a bottom plate 1, a pull drawer 2, a fixed box 3, a slicing mechanism 4 and a push mechanism 5. The top of the bottom plate 1 is provided with a fixed box 3, and the sliding type inside the fixed box 3 is provided with a hand drawer 2. The top of the bottom plate 1 A push mechanism 5 is connected between the left and right sides, and a slicing mechanism 4 is provided on the top of the fixed box 3. When potatoes need to be sliced, first adjust the angle of the knife face, then cut out a plane at the bottom of the potatoes, and place the bottom of the potatoes At the position of the mouth of the blade 41, then start the push mechanism 5 to work, so that the push mechanism 5 drives the potatoes to move left and right on the blade 41, and the cut potato slices will fall into the fixed box 3. After slicing, the push mechanism 5 can be closed, and the hand can be pulled Pull drawer 2 to collect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com