Oxidable biodegradable cross-linked polyhydrocarbon heat shrinkable film

A heat-shrinkable film and biodegradable technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems that cannot meet the needs of product packaging while it is hot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

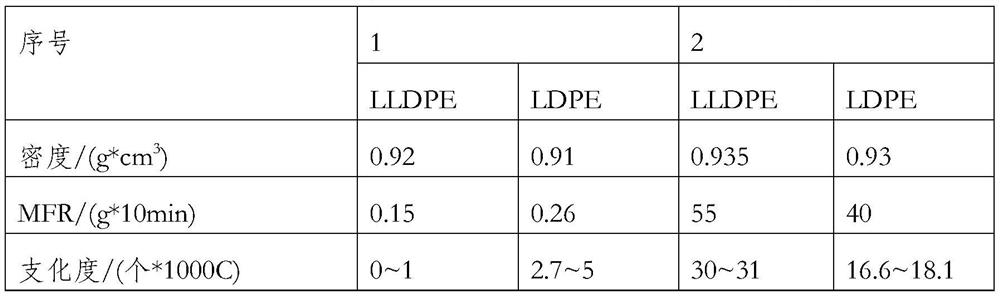

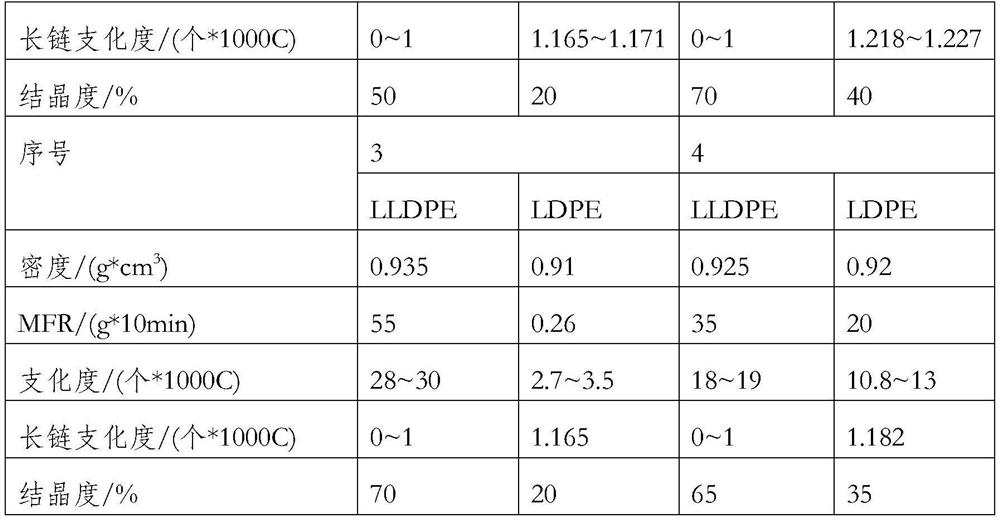

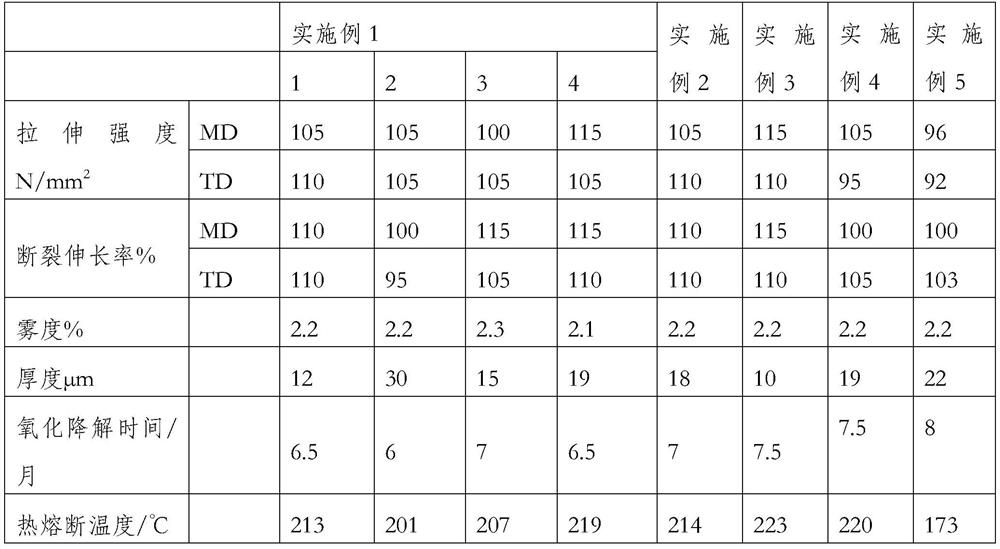

Embodiment 1

[0023] The heat-shrinkable film is composed of three layers of co-extruded and bonded film, namely the outer layer, the middle layer and the inner layer;

[0024] Weigh the raw materials of each layer according to the total raw materials, specifically, the raw materials of the first outer layer: 2.5% pp and 3% opening agent; the raw materials of the middle layer: 70% LLDPE, 5% LDPE and 3% slip agent; the raw materials of the second outer layer and The raw materials of the first outer layer are the same;

[0025] The production process includes the following steps:

[0026] (1) Extrusion molding: Mix the raw materials of the outer layer, middle layer and inner layer evenly according to the weight percentage, and send them to each single-screw extruder through each hopper. Extrude the parent piece through the die head; extrude the embryo tube by the flat extrusion down-blowing method, and the high polymer is in a molten state at this time;

[0027] (2) Radiation cross-linking:...

Embodiment 2

[0034] The heat-shrinkable film is composed of three layers of co-extruded and bonded film, namely the outer layer, the middle layer and the inner layer;

[0035] Weigh the raw materials of each layer according to the total raw materials, specifically, the first outer layer raw materials: 1.5%-5% pp and 2%-4% anti-blocking agent; the middle layer raw materials: 70%-85% LLDPE, 3%-10% LDPE and 2%-4% slippery agent; the raw material of the second outer layer is the same as that of the first outer layer, and the selection of each raw material is the same as the serial number 4 in the embodiment 1.

[0036] The production process includes the following steps:

[0037] (1) Extrusion molding: Mix the raw materials of the outer layer, middle layer and inner layer evenly according to the weight percentage, and send them to each single-screw extruder through each hopper. Extrude the parent piece through the die head; extrude the embryo tube by the flat extrusion down-blowing method, an...

Embodiment 3

[0042] The heat-shrinkable film is composed of three layers of co-extruded and bonded film, namely the outer layer, the middle layer and the inner layer;

[0043] Weigh the raw materials of each layer according to the total raw materials, specifically, the first outer layer raw materials: 1.5%-5% pp and 2%-4% anti-blocking agent; the middle layer raw materials: 70%-85% LLDPE, 3%-10% LDPE and 2%-4% smoothing agent; the raw material of the second outer layer is the same as that of the first outer layer, and the selection of each raw material is the same as the serial number 3 in the embodiment 1.

[0044] The production process includes the following steps:

[0045] (1) Extrusion molding: Mix the raw materials of the outer layer, the middle layer and the inner layer evenly according to the weight percentage, and send them to each single-screw extruder through each hopper. The temperature of the extruder is 190 ° C. Extrude the parent piece through the die head; extrude the embr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com