Frame sash assembly production line

A production line and frame fan technology, applied in the field of frame fan assembly production line, can solve the problems of damage to components such as outer frame and inner fan, labor intensity of workers, and production line occupying a large area, so as to achieve a reasonable overall structure, reduce maintenance intensity, and use land area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

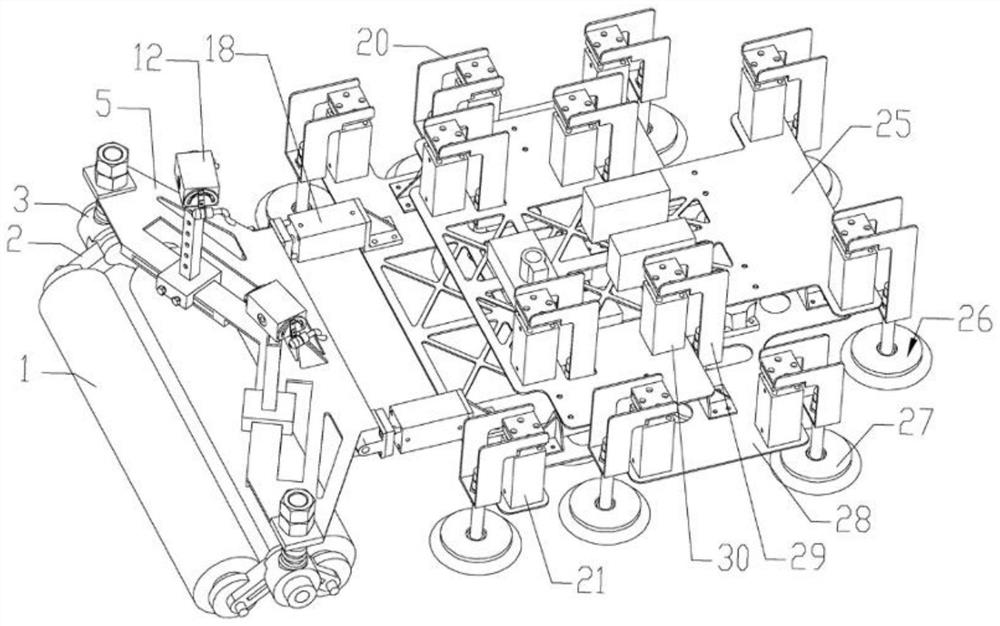

[0037] A frame sash assembly production line, including a supporting mechanism, a conveying mechanism arranged on the supporting mechanism, and a turning mechanism arranged at the previous station of the supporting mechanism; wherein,

[0038] The turning mechanism is configured to transfer the fragile parts 52 delivered from the previous station to the supporting mechanism;

[0039] The supporting mechanism is configured to support the fragile part 52;

[0040] The conveying mechanism is configured to convey the fragile parts 52 on the supporting mechanism to the next station.

[0041] In the preferred solution of this embodiment, the support mechanism includes a first support plate 28, a second support plate 25, and a slider guide rail 32 structure connected between the first support plate 28 and the second support plate 25, so The structure of the slider guide rail 32 includes a slider and a guide rail 32 that are slid and fitted with each other, the slider is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com