Capacitor nail coil and nail deviation detection method and detection device

A detection method and capacitor technology, applied to electromagnetic measuring devices, measuring devices, electrical devices, etc., can solve problems such as abnormal product parameters and short-circuit defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

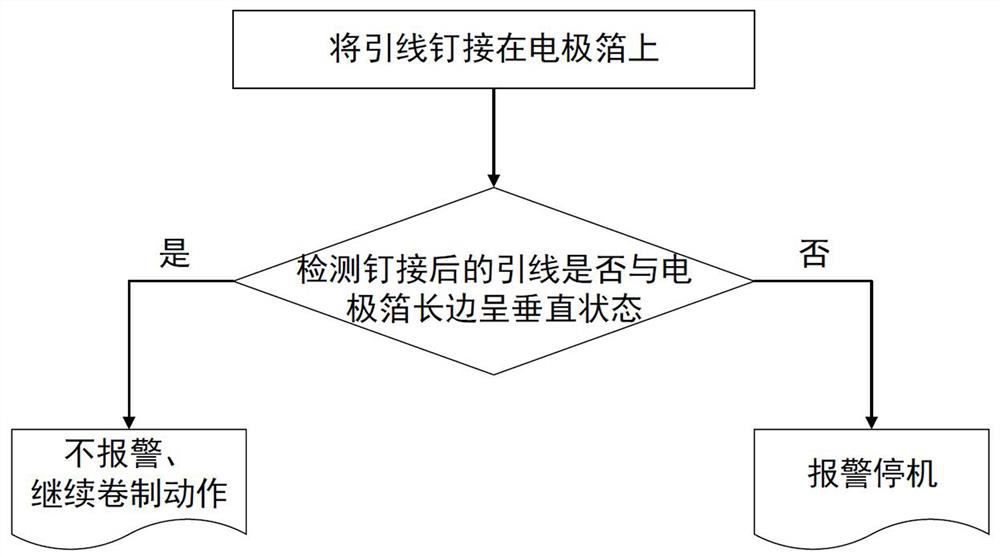

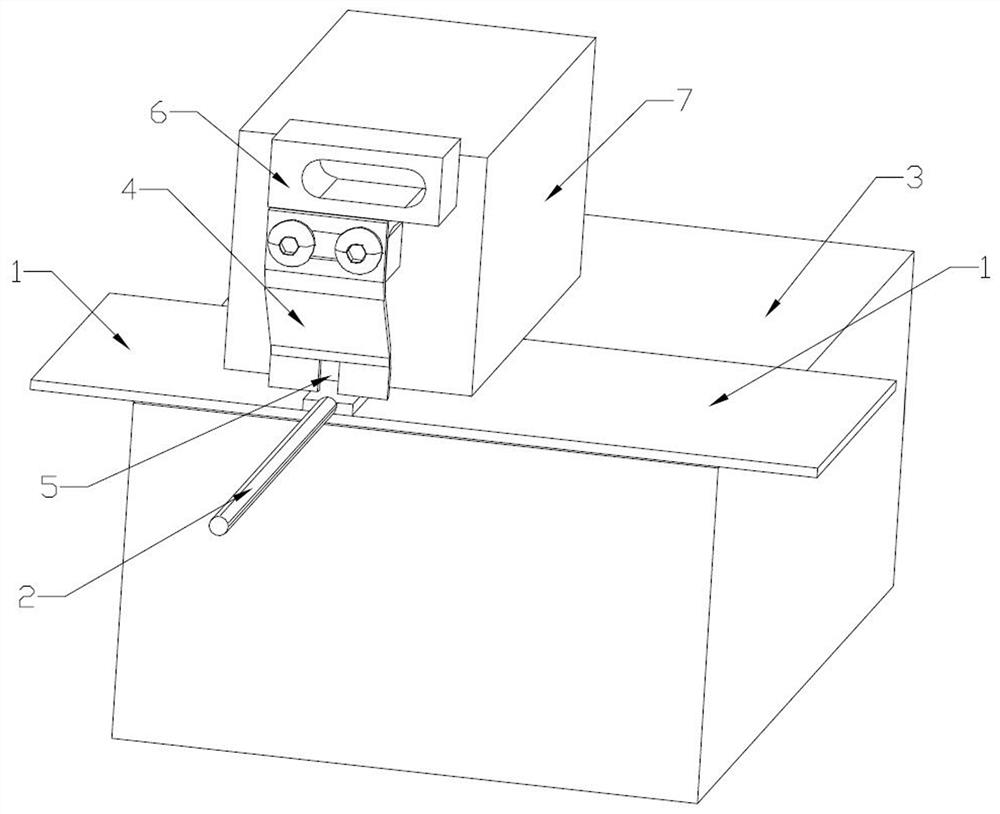

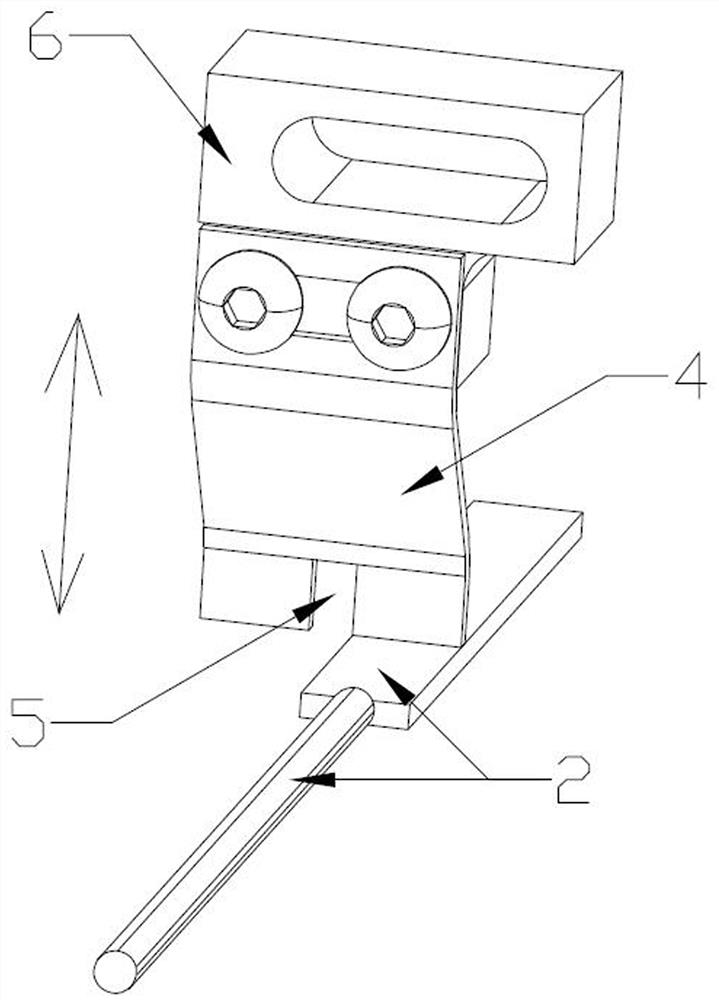

[0026] Such as figure 1 , 2 As shown, the present embodiment provides a method for detecting the deviation of the nail coil of the capacitor, which includes the following steps: during the coiling process of the capacitor core, the lead wire 2 is nailed to the electrode foil 1, and then the nailed lead wire is detected 2 Whether it is perpendicular to the long side of the electrode foil 1, if it is detected to be non-perpendicular, it will alarm and stop, if it is detected to be vertical, it will not alarm and continue the rolling action. Specifically, whether the stapled lead wire 2 is perpendicular to the long side of the electrode foil 1 is detected by the staple deviation detection device.

[0027] Further, the nail deviation detection device includes a conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com