A kind of manufacturing method of LED flexible filament

A manufacturing method and filament technology, which are applied to semiconductor devices of light-emitting elements, lighting and heating equipment, electric solid-state devices, etc., can solve the problems of unreasonable temperature curve setting, virtual welding of LED chips, affecting reliability, etc. The effect of proportional short circuit failure, enhanced welding strength and high product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

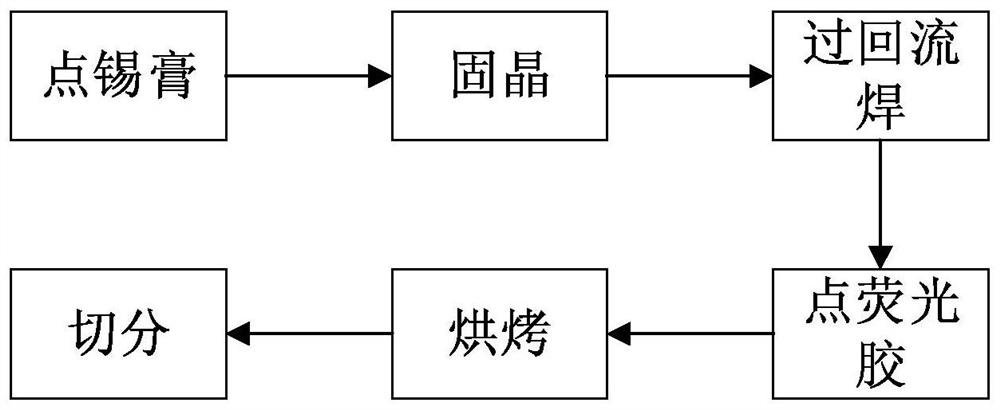

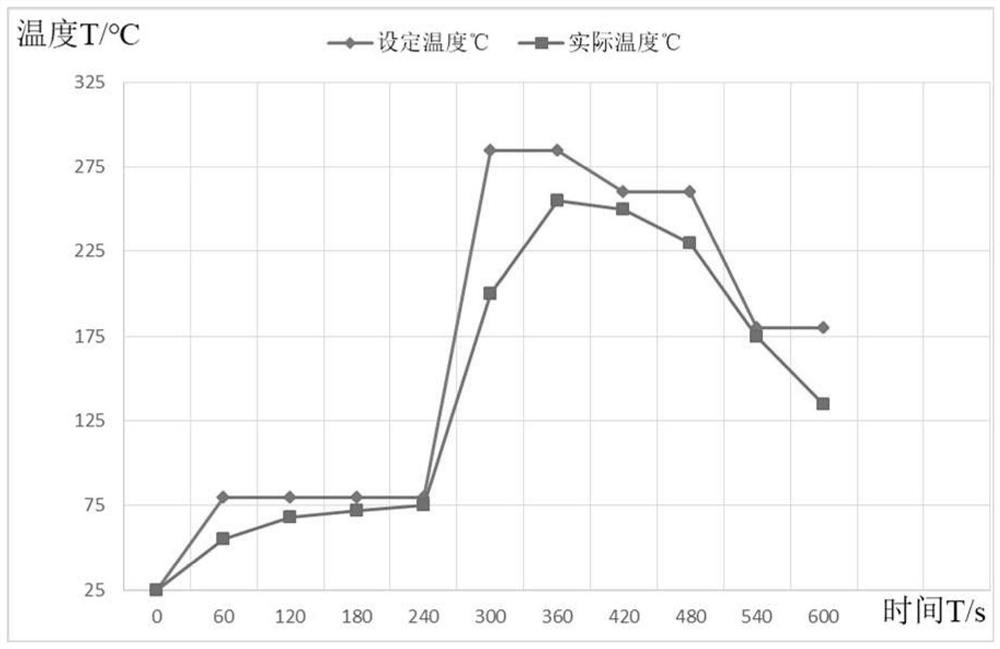

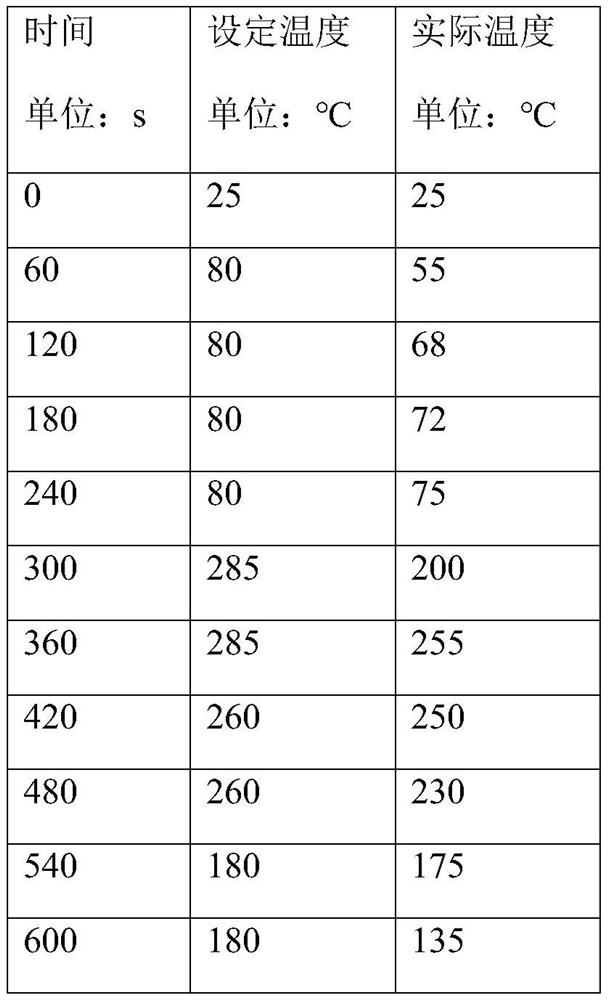

[0020] The present invention provides a mature LED flexible filament production process for the key process in the production process - tinning in order to solve the existing problems in the prior art, such as abnormal phenomena such as virtual soldering of LED chips, short circuit, etc., and solder flux residues affecting reliability. The temperature control of paste and reflow soldering makes the soldering area of LED chips uniform, moderate in height, high in soldering strength, good in push-pull force, less flux residue, and high in product reliability.

[0021] The invention provides a method for manufacturing a flexible LED filament, wherein the flexible LED filament includes a flexible substrate, an LED chip, fluorescent glue, etc., the flexible substrate is made of O-state aluminum or FPC, and the flexible substrate is regularly arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com