Mini double-optical-filter switcher with small lens

A dual-filter, mini-type technology, applied in the directions of instruments, optics, camera bodies, etc., can solve the problems of complex process, affecting product verticality, high labor and material costs, simplifying the process and reducing short circuits. Poor, the effect of simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

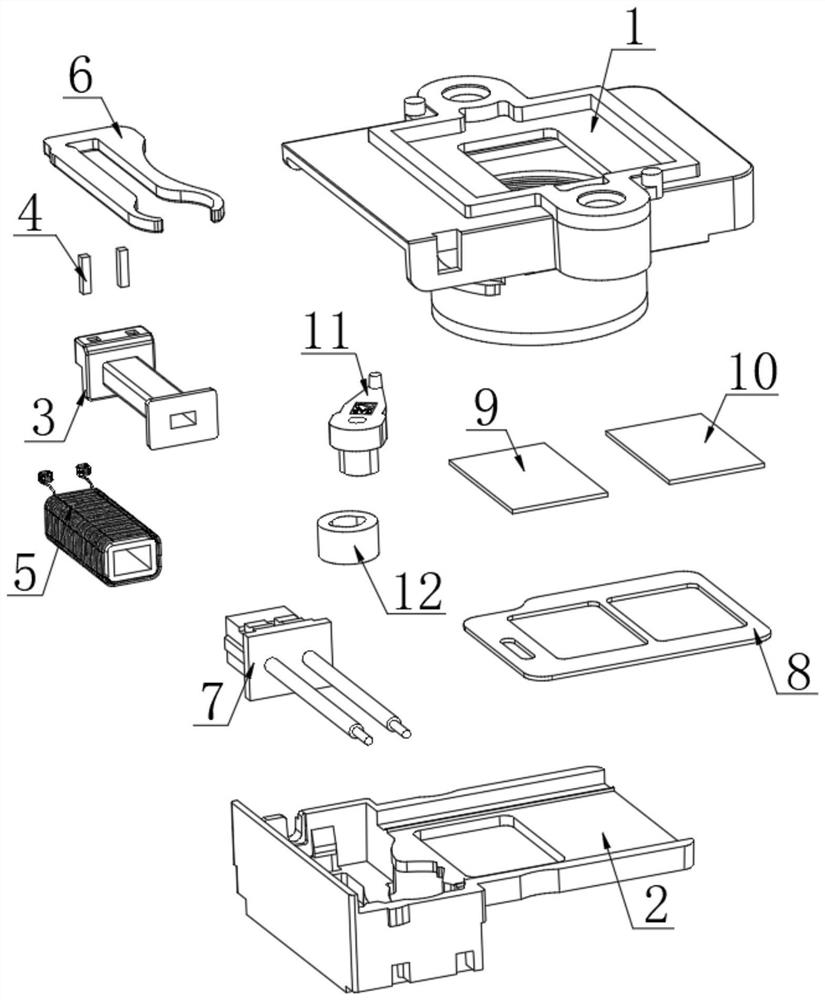

[0014] see figure 1 , this embodiment provides a mini-type dual filter switcher with small lens, including a face cover 1 and a bottom case 2, the face cover 1 and the bottom case 2 are detachable and connected, and the bottom of the inner wall of the bottom case 2 is provided with a wire frame 3, and the wire Pins 4 are arranged in the slots on both sides of the top of one end of the rack 3, and each pin 4 is inserted into the slot of the wire rack 3. A coil 5 is wound around the middle of the wire rack 3, and both ends of the coil 5 are respectively connected with the two sockets. Needle 4 is welded, a U-shaped iron 6 is provided on the side of the wire rack 3 away from the bottom case 2, the straight end of the U-shaped iron 6 is inserted into the square hole in the middle of the wire rack 3, and a terminal wire 7 is provided on the top of the wire rack 3 away from the bottom case 2. , the two ends of the terminal wire 7 are respectively welded with two pins 4, a magnet 12 ...

Embodiment 2

[0018] see figure 1 , on the basis of Embodiment 1, further improvements have been made: the contact surface of the crank handle 11 and the magnet 12 is fixed by dispensing connection, the face cover 1 and the bottom case 2 are fixed by plugging and buttoning, and the hook on the top of the crank handle 11 penetrates the microphone The sliding groove at the end of the pull tab 8 is slidably connected to it, and the crank handle 11 and the magnet 12 are connected and fixed by dispensing glue, which not only effectively improves the stability of the installation and connection, but also effectively guarantees the installation and connection. Convenience, avoiding the complicated steps of the traditional connection method and affecting the installation efficiency. Through the sliding connection between the crank handle 11 and the Mylar sheet 8, when the coil 5 generates a magnetic field, when the magnet 12 drives it to swing left and right, Drive the Mylar 8 to form a pull switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com