Power distribution cabinet for electric power engineering

A technology for power engineering and power distribution cabinets, applied in the substation/distribution device casing, electrical components, substation/switch layout details, etc., can solve problems such as being easily affected by the external environment, difficult to dissipate heat, hidden safety hazards, etc., to improve The effect of automatic control rate, reduction of energy output, and prevention of cold air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

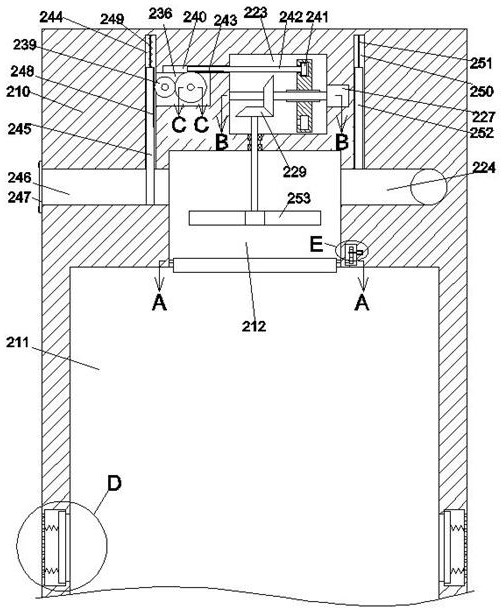

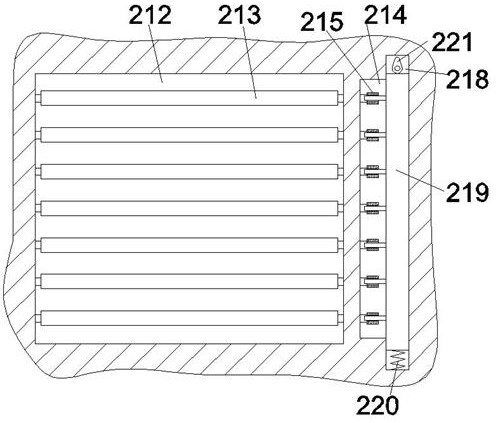

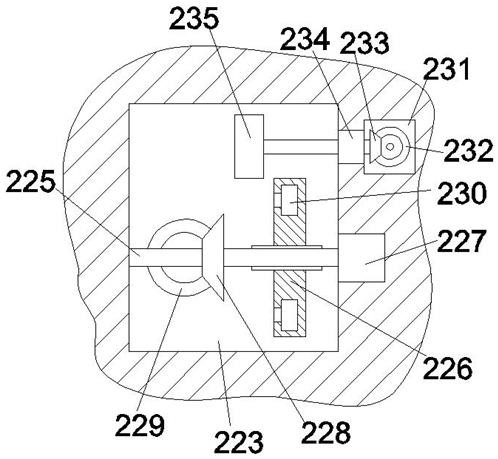

[0027] The cold air is directly supplied through the cold air channel 224, so that the cold air flows into the equipment inner cavity 211 through the air inlet cavity 212, and realizes rapid cooling in the equipment inner cavity 211, so that it is not affected by the external environment and achieves a rapid cooling effect. The second motor 227 drives the first rotating shaft 225 to rotate, and the first bevel gear 228 driven by the first rotating shaft 225 drives the second bevel gear 229 to rotate, wherein because the third gear 226 is far away from the fourth gear 235, at this time, the fourth gear 235 is in the non-working state, and then the second bevel gear 229 drives the fan blade 253 to rotate, so that the cold air is quickly sent into the equipment cavity 211, and the second motor 227 is controlled to stop rotating until the temperature of the equipment cavity 211 is lowered. The block 256 is pressed by the third spring 258 to automatically close the opening 254, ther...

Embodiment 2

[0029] When ordinary heat dissipation is required, the first motor 238 drives the second gear 237 to rotate, so that the second gear 237 drives the second rack 243 and the linkage slider 242 to slide to the left, and then the linkage slider 242 drives the third gear 226 is meshed with the fourth gear 235. At the same time, the first gear 239 is driven to rotate when the second rack 243 rotates. Since the rotation direction of the first gear 239 is opposite to that of the second rack 243, the second rack 243 is rotated. A gear 239 drives the first rack 248 and the second baffle plate 245 to overcome the top pressure of the second spring 249 to slide upwards, so that the bottom section of the second baffle plate 245 is away from the air inlet passage 246, so as to realize the opening of the air inlet passage 246, and at the same time , because the first baffle plate 252 is subjected to automatic gravity, the bottom section of the first baffle plate 252 extends into the cold air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com