Folding modular box-type slide rail photovoltaic module

A technology for photovoltaic modules and foldable modules, applied in photovoltaic modules, photovoltaic power generation, support structures of photovoltaic modules, etc., can solve the problems of large area and low space utilization, and achieve high light energy utilization, high space utilization, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as Figure 10-11 As shown, a photovoltaic assembly of a folded and assembled box-type slide rail is composed of a central assembly 9, an outer box 10 and an inner box 11 to form a photovoltaic assembly, and the photovoltaic assembly is installed on a light-following platform 16 through a bracket 15; the light-following A photoelectric sensor connected to the photovoltaic module is provided on the platform 16, and a pitch direction stepper motor 18 for adjusting the pitch angle of the photovoltaic module and a horizontal direction stepper motor 19 for adjusting the horizontal angle of the photovoltaic module are provided on the bracket 15; The photoelectric sensor receives the illumination angle signal of the photovoltaic module, and then controls and adjusts the pitch angle and horizontal angle of the photovoltaic module through the control box 17 on the light tracking platform 16, so that the light tracking can be realized.

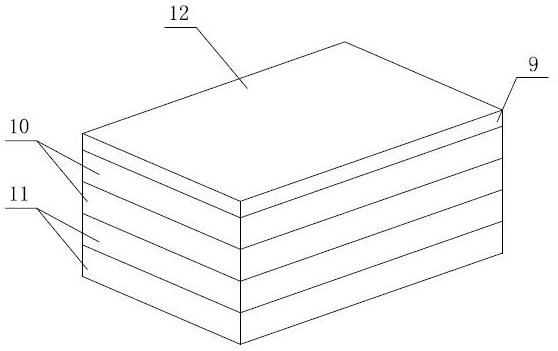

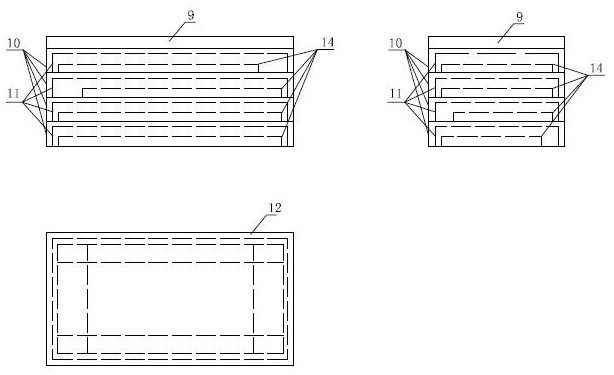

[0040] Such as Figure 1-2As shown, t...

Embodiment 2

[0042] On the basis of Embodiment 1, the outer boxes 10 are detachably connected. In this embodiment, a buckle structure can be adopted to facilitate disassembly and installation, and realize the addition and deletion of the outer box body 10 .

Embodiment 3

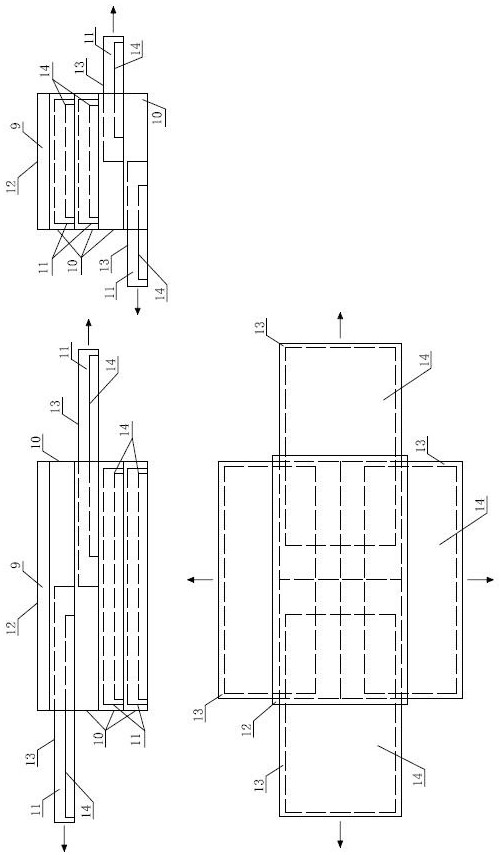

[0044] On the basis of Embodiment 1 or 2, each of the outer boxes 10 is provided with two inner boxes 11, and the positions of the slide rails in the upper and lower outer boxes 10 are perpendicular to each other, that is, they are located in the upper outer box. The inner box body 11 in the body 10 is perpendicular to the sliding direction of the inner box body 11 located in the lower outer box body 10; at the same time, the sliding directions of the two inner box bodies 11 in the same outer box body 10 are opposite, and the same outer box body 10 The sliding directions of the photovoltaic panels 3 14 in the two inner boxes 11 are opposite.

[0045] In order to improve the utilization rate of space, the present invention adopts the method of hierarchical folding and unfolding, and its gradual unfolding steps are as follows:

[0046] 1. If image 3 As shown, when the first stage is deployed, the inner box body 11 protrudes outwards.

[0047] 2. After the first-level expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com