Assembly line beating machine for cakes

An assembly line and beating machine technology, applied in baking, baked food, food science, etc., can solve problems such as low efficiency, difficulty in working for a long time, uneven manual beating strength, etc., and achieve the effect of consistent standards and uniform strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

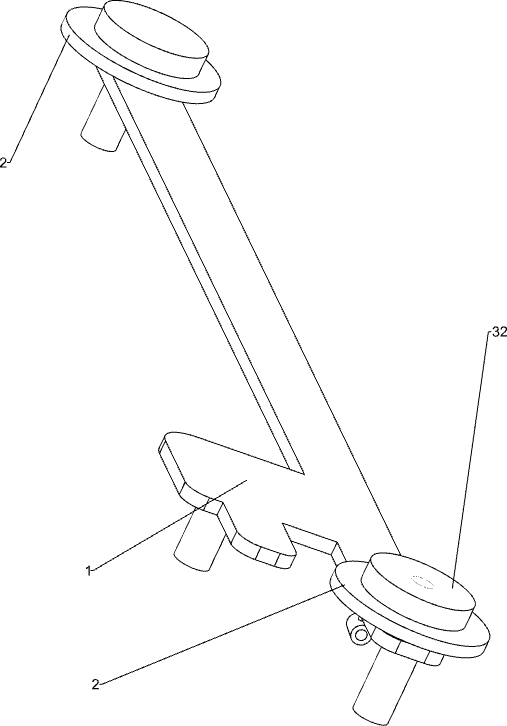

[0022]A cake assembly line tapping machine, such asFigure 1-3 As shown, it includes a support 1, a support disk 2 and a transfer mechanism 3. The tops of the front and rear sides of the support 1 are fixedly connected with a support disk 2, and the top of the support disk 2 is connected with a transfer mechanism 3.

[0023]When people need to use this machine, they first place the items to be processed on the conveying mechanism 3, and then people use tools to tap the items to be processed.

Embodiment 2

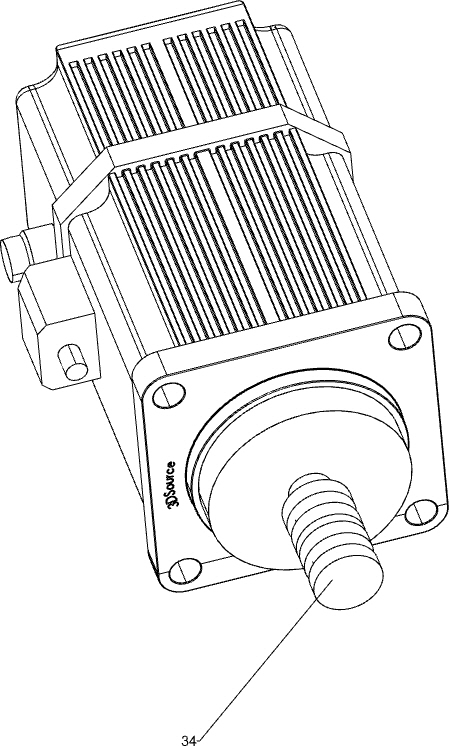

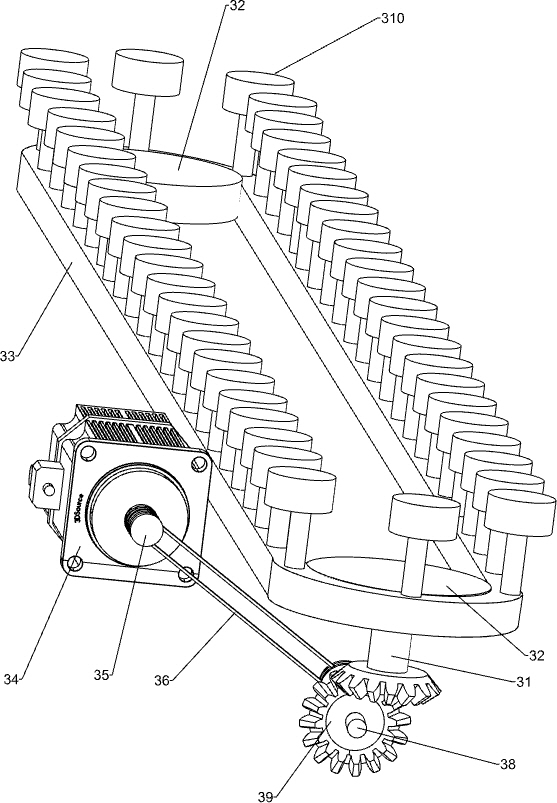

[0025]On the basis of Example 1, such asFigure 3-8 As shown, the transmission mechanism 3 includes a first rotating shaft 31, a rotating disk 32, a transmission belt 33, a motor 34, a double groove pulley 35, a first flat belt 36, a first pulley 37, a second rotating shaft 38, and a bevel gear 39. , The tray 310 and the fixed block 311, the top right side of the bracket 1 is provided with a motor 34, the output shaft of the motor 34 is provided with a double-groove pulley 35, the bottom of the rear side of the bracket 1 is fixedly connected with a fixed block 311, and the lower part of the fixed block 311 rotates A second rotating shaft 38 is connected. The front end of the second rotating shaft 38 is provided with a first pulley 37. A first flat belt 36 is wound between the first pulley 37 and the rear side of the double-groove pulley 35. The rear side of the support 1 is rotatably connected with a first rotating shaft 31, the bottom of the first rotating shaft 31 and the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com