Application of granules containing cheese pieces in liquid food, and methods for making granules and liquid food

A technology for liquid food and cheese, which is applied in the field of liquid food and the preparation of the liquid food, and can solve the problems of cheese flavor loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

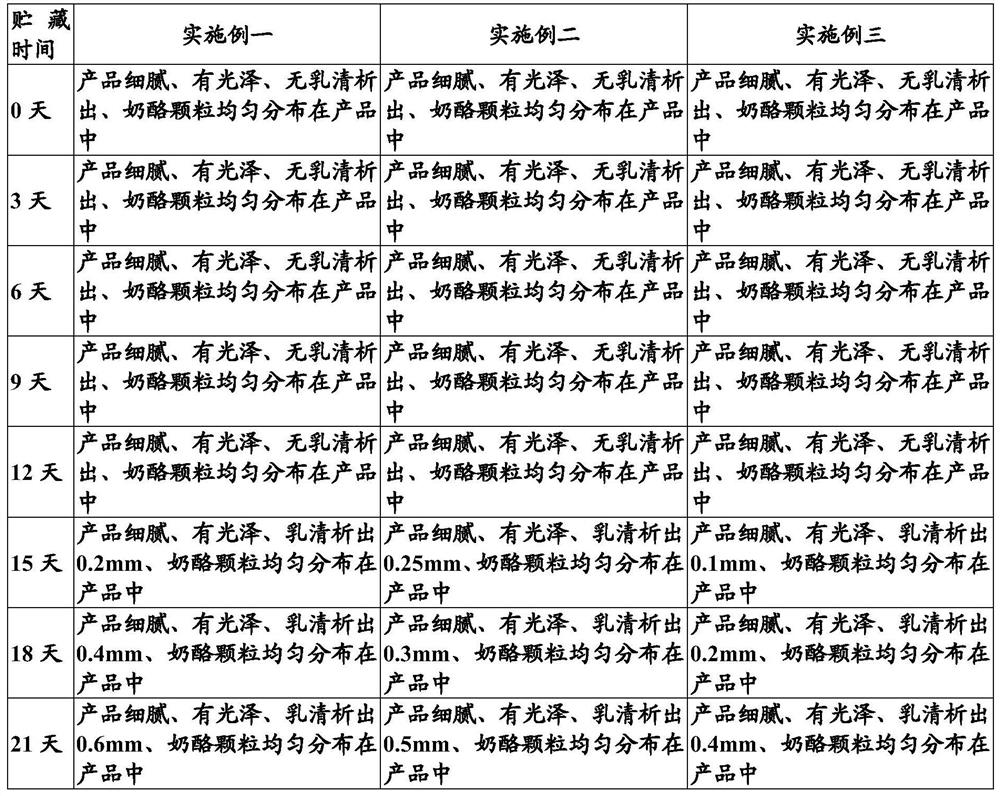

Embodiment 1

[0090] 1. Preparation of Pellets Containing Cheese Blocks

[0091] Ingredients: cream cheese, calcium chloride, sodium alginate, carrageenan, white sugar, fructose syrup, citric acid, water;

[0092] making process:

[0093] (1) Preparation of cheese blocks: Cut the cream cheese into cubes of 5mm*5mm*5mm to make cheese blocks.

[0094] (2) Coating powder of cheese block: mix cheese block with calcium chloride powder, the quality of calcium chloride powder is 0.01% of the mass of cheese block, stir evenly, ensure that powder can be stuck on each cheese block.

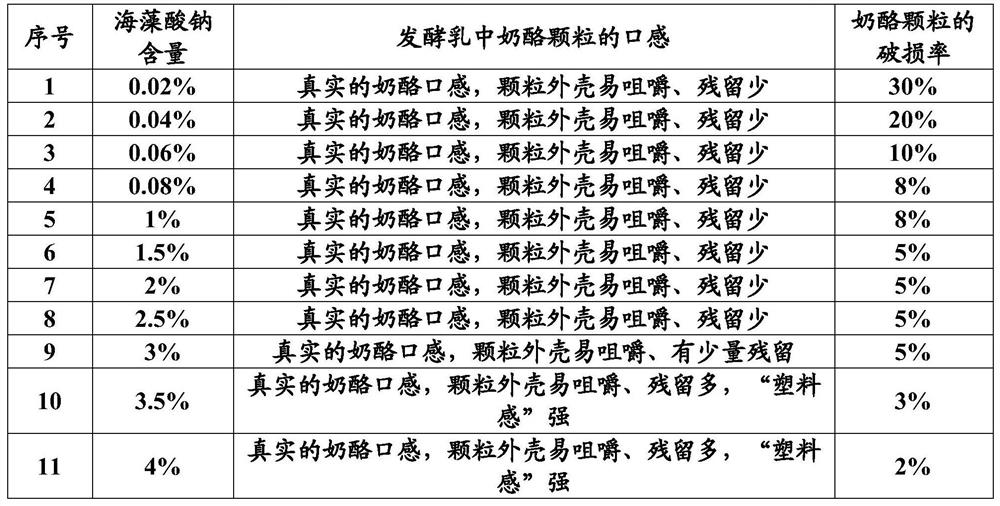

[0095] (3) Wrapping glue: get sodium alginate, carrageenan and calcium chloride by mass ratio and add in water to obtain colloid solution (sodium alginate 1%, carrageenan 0.01%, calcium chloride 0.03%, surplus is water), then Pour the colloidal solution into the jacketed pot and start stirring. Disperse the powder-coated cheese cubes with a strainer, slowly pour them into the colloid solution, the cheese cubes continu...

Embodiment 2

[0120] 1. Preparation of Pellets Containing Cheese Blocks

[0121] Raw materials: mozzarella cheese, calcium chloride, sodium alginate, carrageenan, white sugar, citric acid, water;

[0122] making process:

[0123] (1) Preparation of cheese blocks: cut mozzarella cheese into cubes of 5mm*5mm*5mm, and make cheese blocks.

[0124] (2) Coating powder of cheese block: mix cheese block with calcium chloride powder, the quality of calcium chloride powder is 0.01% of the mass of cheese block, stir evenly, ensure that powder can be stuck on each cheese block.

[0125] (3) Glue wrapping: get sodium alginate, carrageenan and calcium chloride by mass ratio and add in water to obtain colloidal solution (1.5% sodium alginate, 0.02% carrageenan, 0.03% calcium chloride, and the balance is water), then Pour the colloidal solution into the jacketed pot and start stirring. Disperse the powder-coated cheese cubes with a strainer, slowly pour them into the colloid solution, the cheese cubes c...

Embodiment 3

[0150] 1. Preparation of Pellets Containing Cheese Blocks

[0151] Ingredients: cream cheese, calcium chloride, sodium alginate, carrageenan, white sugar, fructose syrup, citric acid, water;

[0152] making process:

[0153] (1) Preparation of cheese blocks: Cut the cream cheese into cubes of 5mm*5mm*5mm to make cheese blocks.

[0154] (2) Coating powder of cheese block: mix cheese block with calcium chloride powder, the quality of calcium chloride powder is 0.01% of the mass of cheese block, stir evenly, ensure that powder can be stuck on each cheese block.

[0155] (3) Wrapping glue: get sodium alginate, carrageenan and calcium chloride by mass ratio and add in water to obtain colloid solution (sodium alginate 1%, carrageenan 0.01%, calcium chloride 0.03%, surplus is water), then Pour the colloidal solution into the jacketed pot and start stirring. Disperse the powder-coated cheese cubes with a strainer, slowly pour them into the colloid solution, the cheese cubes continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com