Preparation method of semi-baked and semi-fried green tea

A green tea and frying technology, which is applied in the field of preparation of half-baked and half-fried green tea, can solve the problems of aroma emission, poor shape of green tea, easy sticking into lumps, etc., and achieve the effect of excellent sensory feeling and green color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

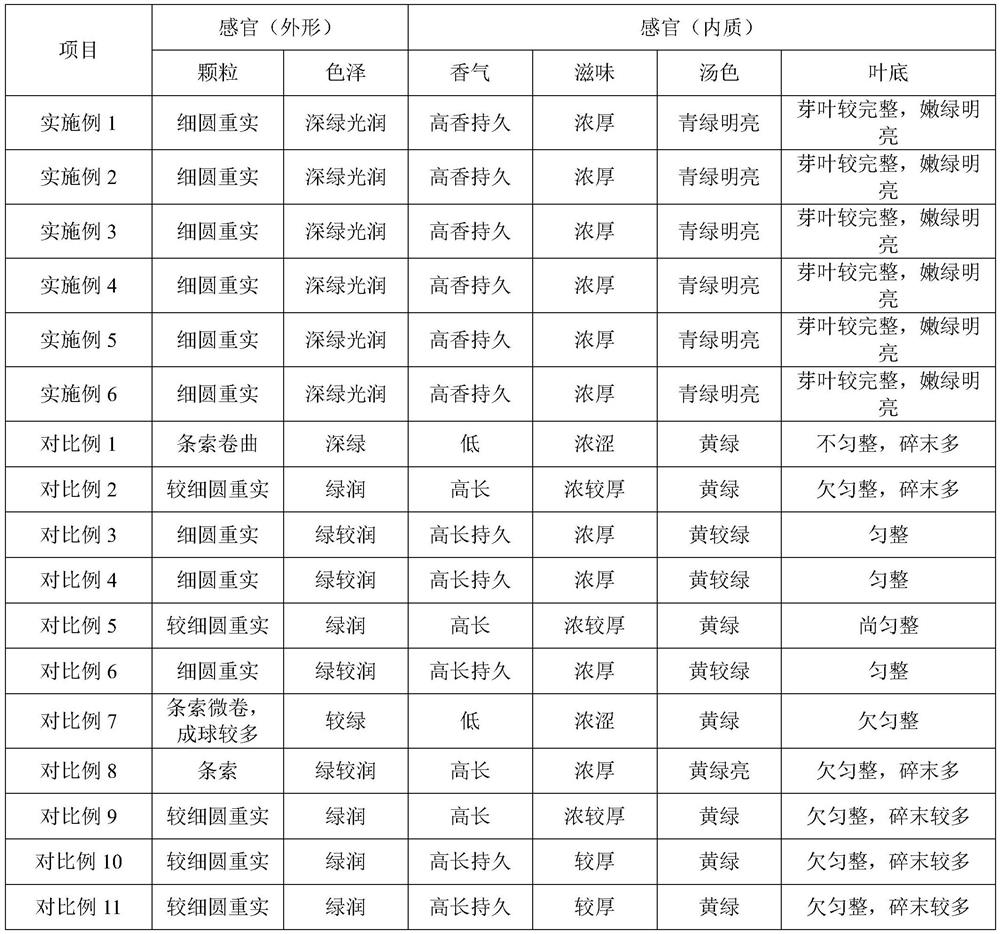

[0038] General embodiment: a kind of preparation method of half-baked and half-fried type green tea comprises the following preparation steps:

[0039] (1) Acceptance of fresh leaves: select stretched and complete fresh green tea leaves, in which one bud and two leaves account for 40wt%, one bud and three leaves account for 60wt%, and the length of the new shoot is 4-7cm;

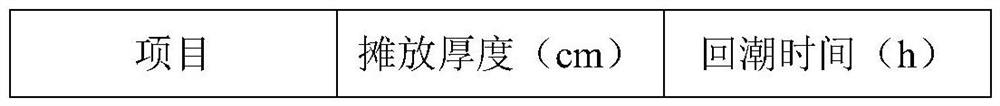

[0040] (2) Spreading: spread the selected fresh leaves in the withering tank, the spreading thickness is 15cm, the ambient temperature is 20°C, and the humidity is 80%; the spreading time is 5.5h, during which it is lightly turned every 1.5h once;

[0041] (3) Finishing: Put the fresh leaves after spreading and withering in a finishing machine for finishing. The finishing temperature is 340-350°C. The temperature of the finishing leaves in the barrel is 85-90°C. The water content of fresh leaf is 55-57wt%;

[0042](4) Static resurgence: after the fresh leaves after greening are cooled, they are allowed to...

Embodiment 1

[0052] Embodiment 1: a kind of preparation method of half-baked and half-fried type green tea comprises the following preparation steps:

[0053] (1) Acceptance of fresh leaves: select stretched and complete fresh green tea leaves. In the fresh green tea leaves, one bud and two leaves account for 43wt%, one bud and three leaves account for 57wt%, and the length of the new shoot is 4-7cm;

[0054] (2) Spreading: spread the selected fresh leaves in the withering tank, the spreading thickness is 13cm, the ambient temperature is 19°C, and the humidity is 75%; the spreading time is 5.5h, during which it is lightly turned every 1.8h once;

[0055] (3) Finishing: Put the fresh leaves after spreading and withering in a finishing machine for finishing. The temperature for finishing is 345°C. is 56wt%;

[0056] (4) Static resurgence: after the fresh leaves after greening are cooled, they are allowed to stand for resurgence. The thickness of the standing resurgence is 53cm, and the res...

Embodiment 2

[0066] Embodiment 2: a kind of preparation method of half-baked and half-fried type green tea comprises the following preparation steps:

[0067] (1) Acceptance of fresh leaves: select stretched and complete fresh green tea leaves, in which one bud and two leaves account for 40wt%, one bud and three leaves account for 60wt%, and the length of the new shoot is 4-7cm;

[0068] (2) Spreading: spread the selected fresh leaves in the withering tank, the spreading thickness is 10cm, the ambient temperature is 18°C, and the humidity is 70%; the spreading time is 5h, and lightly turn over once every 1.5h during the spreading ;

[0069] (3) Finishing: Put the fresh leaves after spreading and withering in the finishing machine for finishing. The finishing temperature is 340°C. 55wt%;

[0070] (4) standing to regain moisture: after cooling the fresh leaves after finishing, let stand to regain moisture, and the static regaining moisture spread thickness is 50cm, and the moisture regaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com