High-efficiency filter

A high-efficiency filter and filter element technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of high cost, achieve low cost, increase vibration amplitude, and improve cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

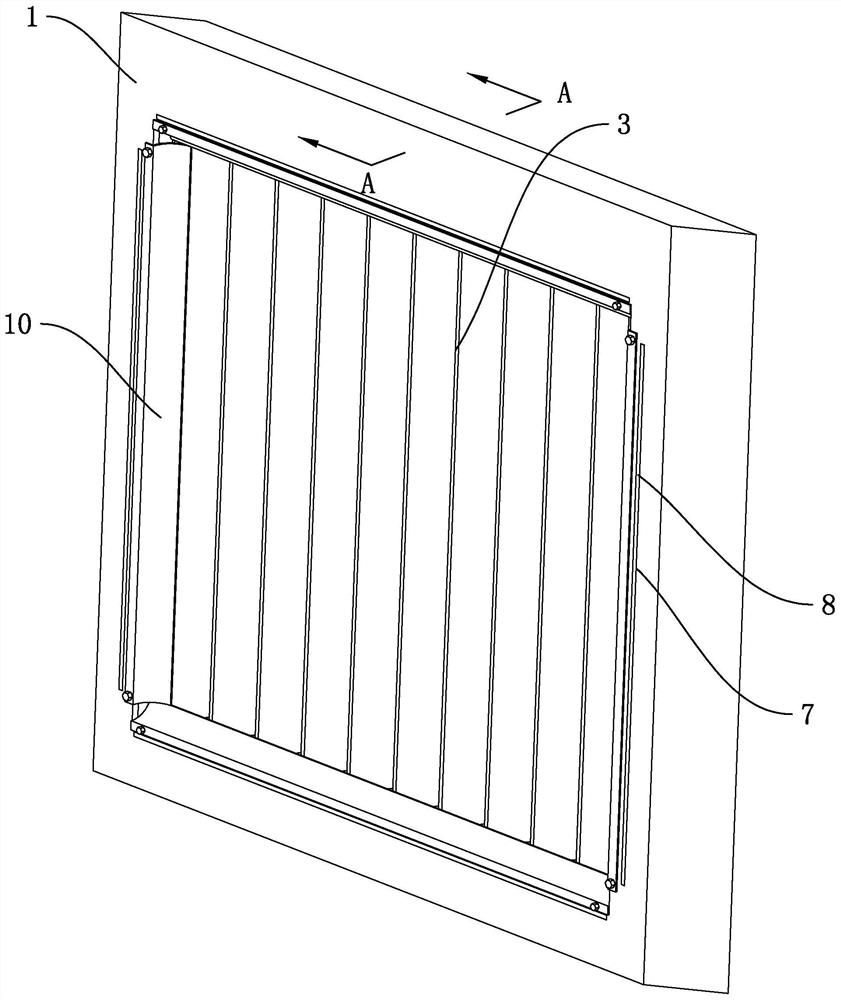

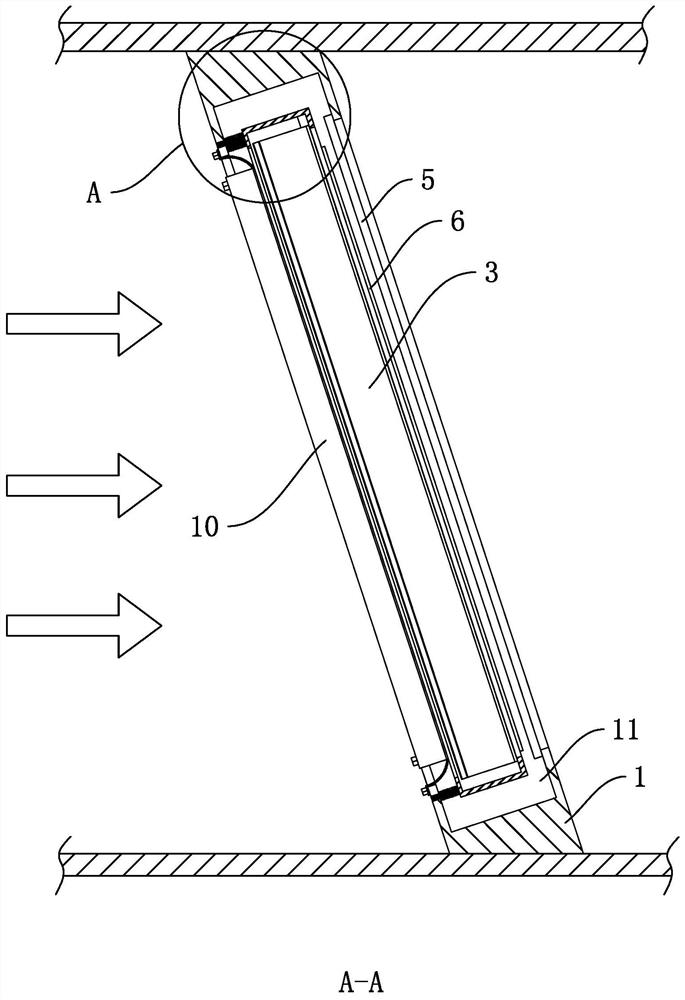

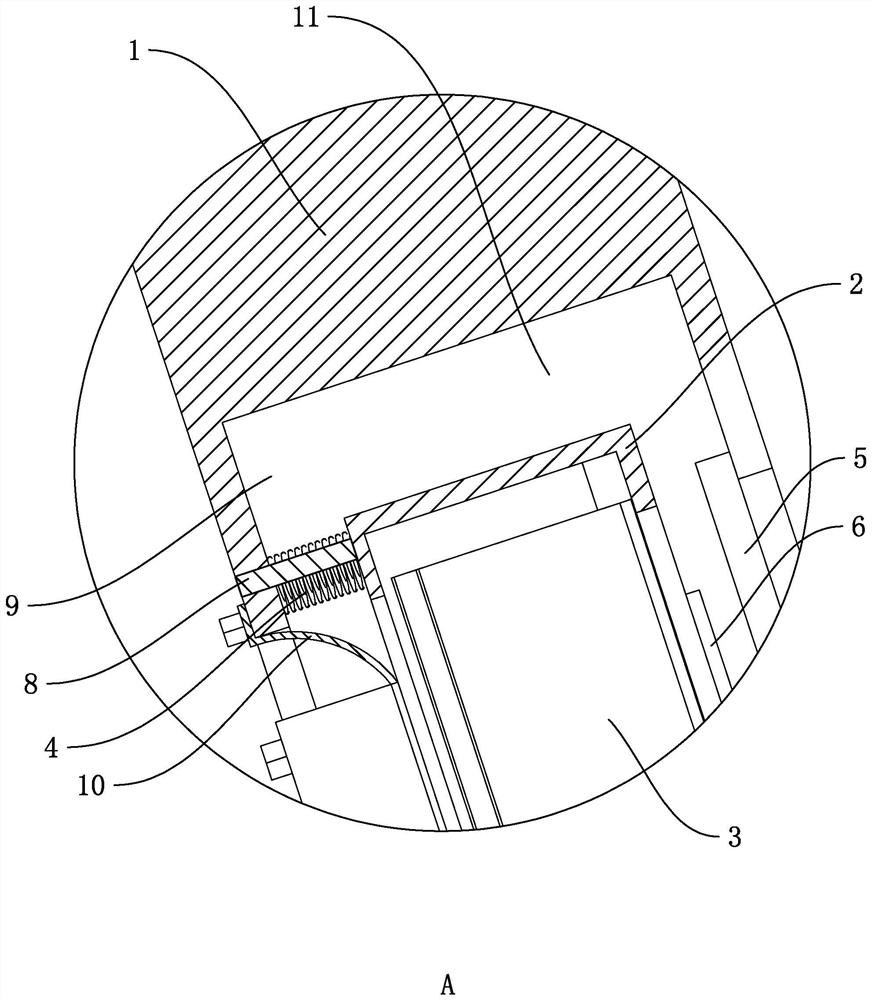

[0033] Such as figure 1 and figure 2 As shown, a high-efficiency filter includes a fixed outer frame 1 arranged in a rectangular shape, and the inner walls of the four sides of the fixed outer frame 1 are provided with interconnected sliding grooves 11, and reciprocating sliding in the sliding groove 11 is provided with a Rectangular vibrating frame 2, inside the vibrating frame 2 is fixed with a filter element 3 that is arranged in twists and turns for filtering natural wind, and between the fixed frame 1 and the vibrating frame 2 is provided with a reciprocating sliding mechanism for the vibrating frame 2 elastic piece.

[0034] In actual use, the fixed outer frame 1 is sealed with hot melt glue or bolts on the inner wall of the air inlet pipe, and then, under the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com