Automobile exhaust catalyst production equipment

A production equipment and automobile exhaust technology, applied in the field of welding processing, can solve the problems of inconvenient fixing of workpieces, high use limitations, and affecting processing output, etc., to achieve the effects of reducing use limitations, increasing processing output, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

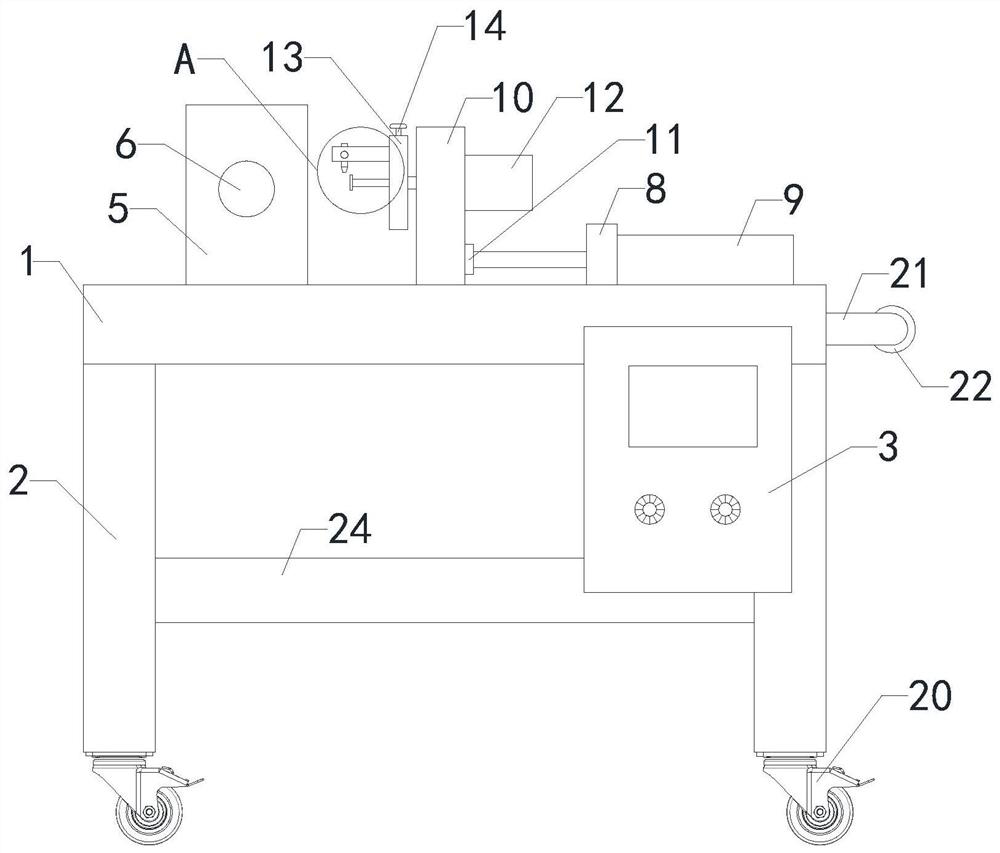

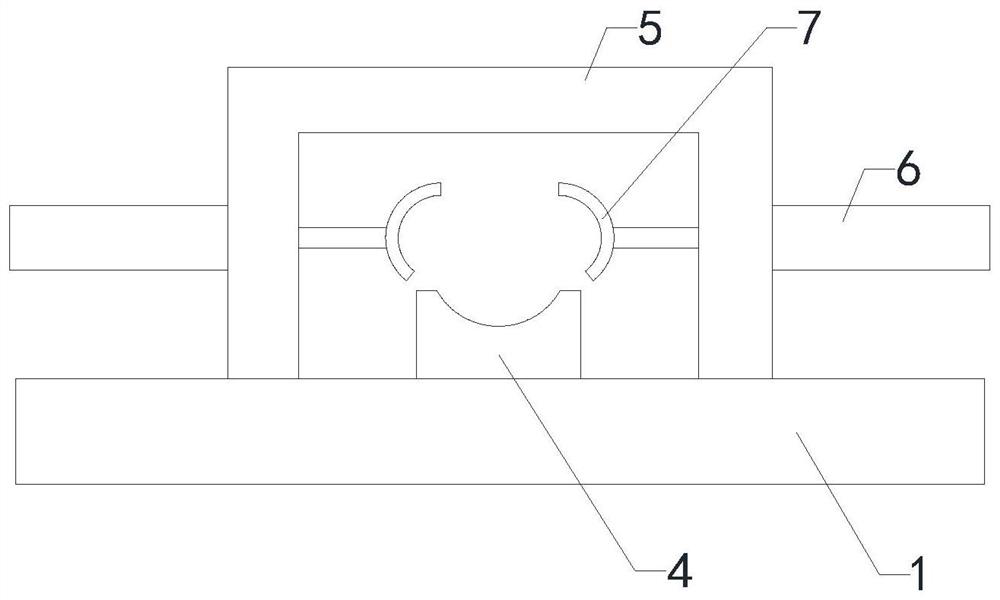

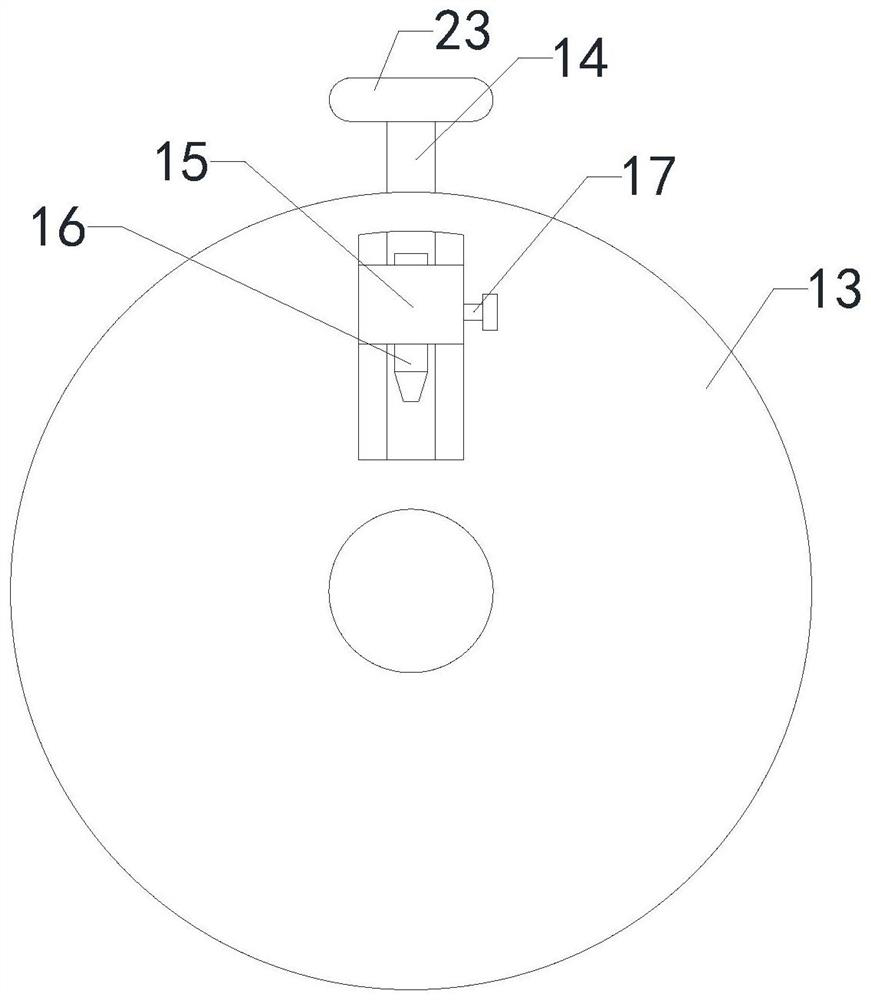

[0020] Such as Figure 1 to Figure 5 As shown, a kind of automobile exhaust catalytic converter production equipment of the present invention comprises base plate 1, welding machine 3, fixing frame 5, two groups of clamping cylinders 6, two groups of feeding cylinders 9, sliding plate 10, driving motor 12, Turntable 13, connecting frame 15 and welding torch 16, four sets of supporting legs 2 are arranged on the bottom of base plate 1, welding machine 3 is fixedly installed on the front end of base plate 1 and one set of supporting legs 2, and positioning seat 4 is fixedly arranged on the top of base plate 1 , the fixed frame 5 is fixedly installed on the top of the base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com