Connecting device applying various standard interfaces on sensor and manufacturing method of connecting device

A technology of connecting device and standard interface, applied in the field of connecting device, can solve the problems of low manufacturing efficiency, large installation space and high manufacturing cost, and achieve the effect of improving product quality level, reducing total manufacturing cost and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

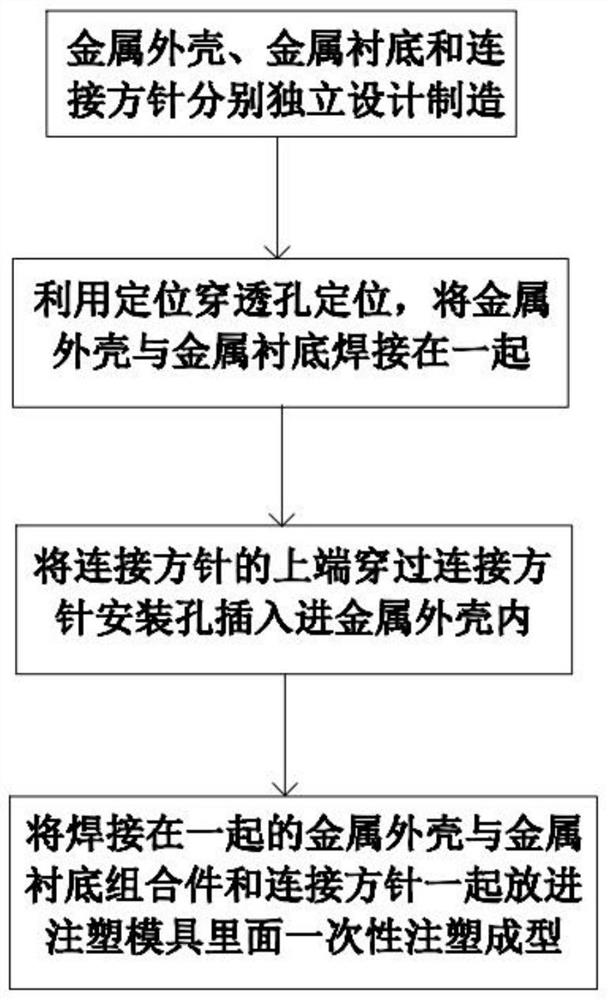

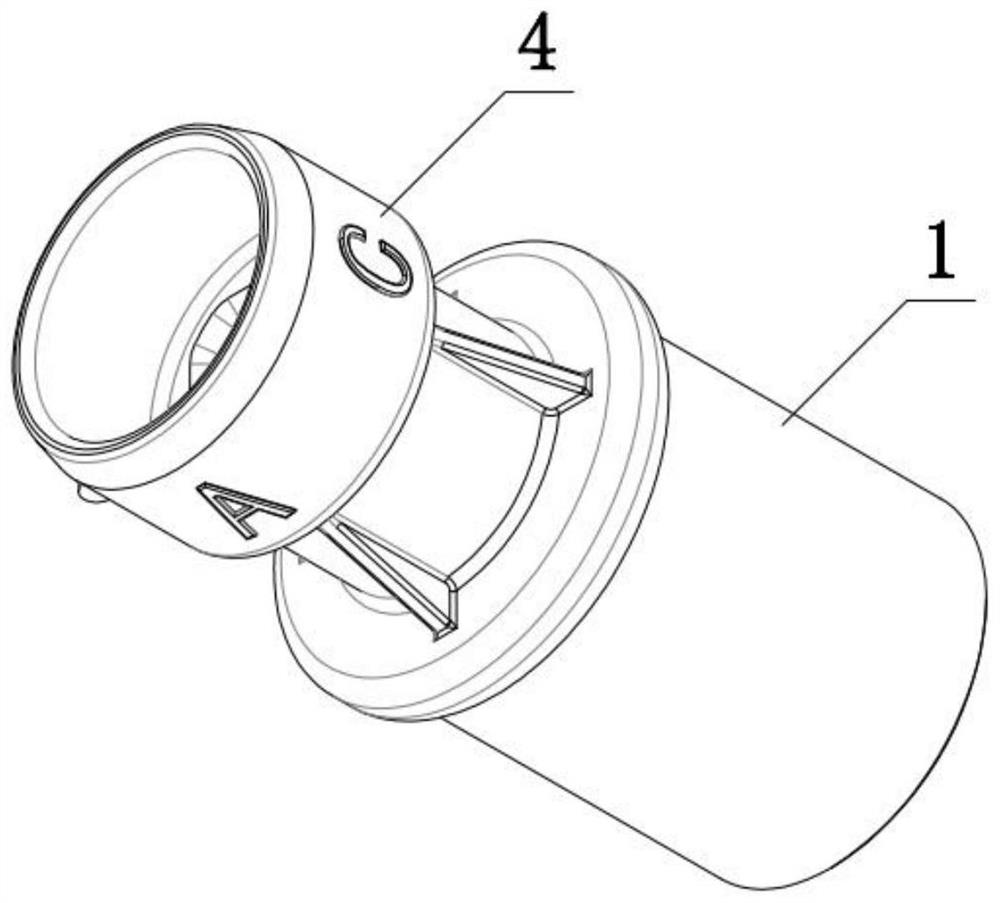

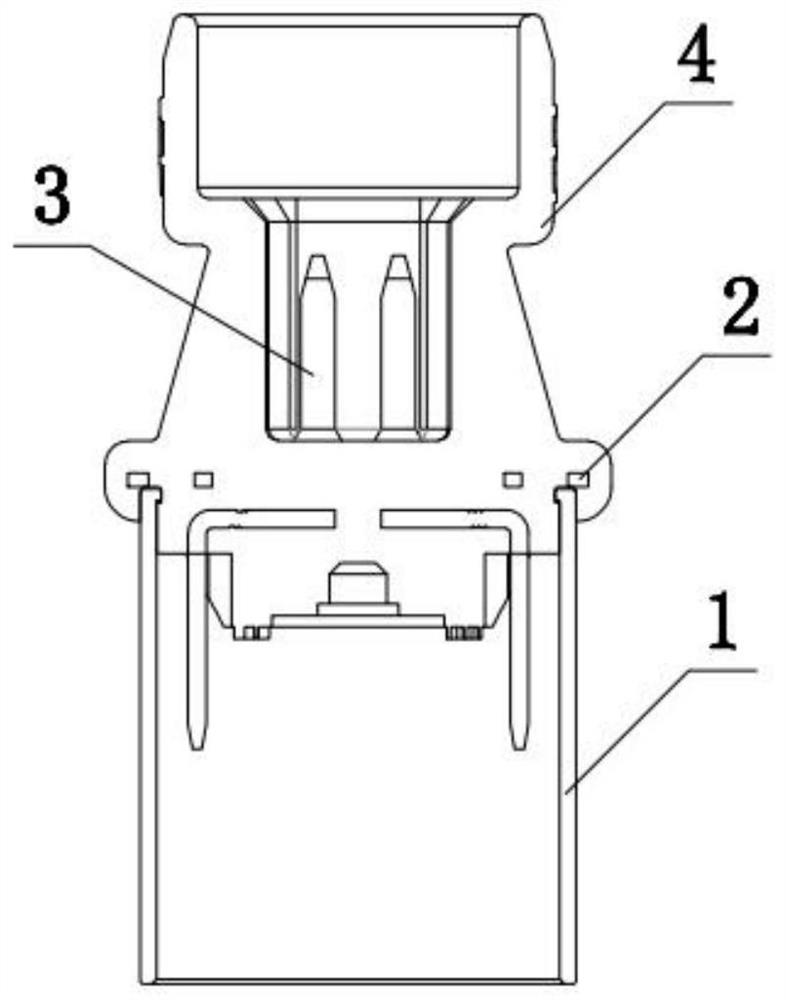

[0034] Such as Figure 1-7 As shown, a method for manufacturing a connection device using various standard interfaces on a sensor, comprising the following steps:

[0035] Step 1: The metal shell, metal substrate and connection guide are independently designed and manufactured. The metal shell is machined using circular metal pipes, the metal substrate is processed by high-speed stamping technology, and the connection guide is processed by stamping sheet materials. ;

[0036] Step 2: Use the positioning penetration holes to position the metal shell and the metal substrate, use a custom-made fixture to clamp and fix the metal shell and the metal substrate, and weld the metal shell and the metal substrate together by welding;

[0037] Step 3: Insert the upper end of the connecting rod into the metal casing through the connecting rod mounting hole;

[0038] Step 4: Put the welded metal shell together with the metal substrate assembly and connection guide into the injection mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com