Converging plate for bottle blowing machine and bottle blowing equipment using converging plate

A manifold and bottle blowing machine technology, applied in the field of bottle blowing molds, can solve the problems of inconvenient installation, maintenance, large air pipe consumption, etc., and achieve the effects of regular structure layout, improved product quality, and improved space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0117] combine Figure 5 , Figure 9 and Figure 10 ,in Figure 5 It is a perspective view of the second embodiment of the blow molding machine manifold of the present invention, Figure 9 It is a structural schematic diagram of the second total air delivery channel of the second embodiment of the manifold for bottle blowing machine of the present invention, Figure 10 It is a schematic structural diagram of the second air inlet channel of the second embodiment of the manifold for bottle blowing machine of the present invention. Several electromagnetic valve groups in the present embodiment also comprise the second inlet valve group 43 and the second exhaust valve group, the second inlet valve group 43 is used for controlling the input of the gas in the mold cavity, and the second exhaust valve group is used for To control the output of gas in the mold cavity; the second intake valve group 43 in this embodiment includes at least one second intake valve, and the second exha...

no. 3 example

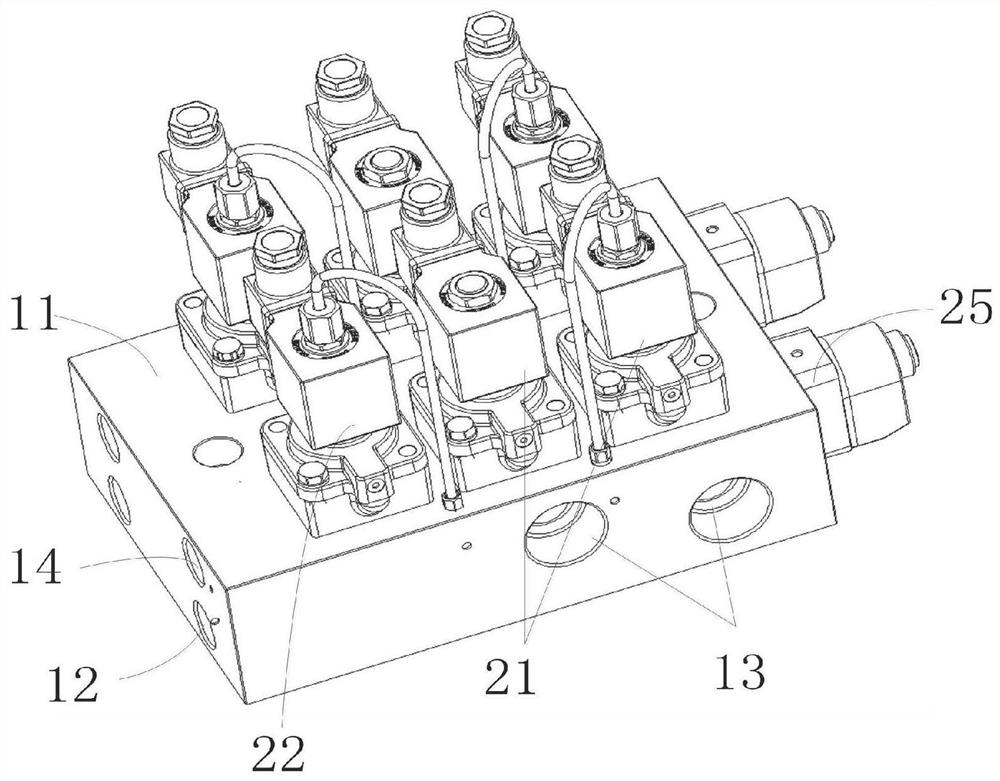

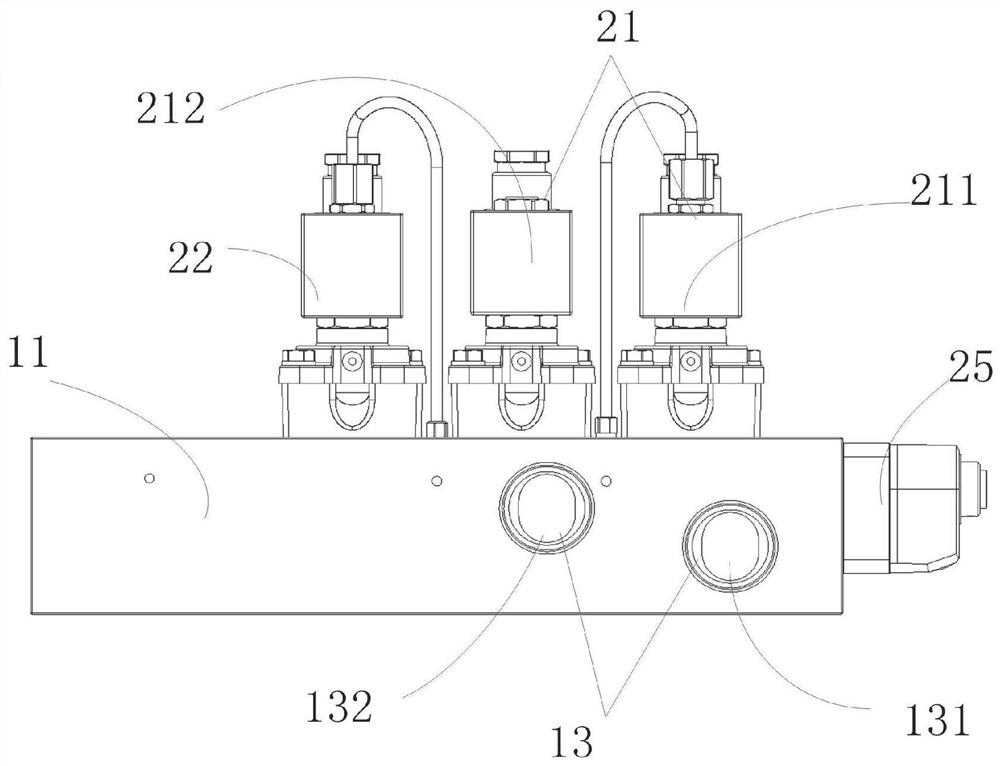

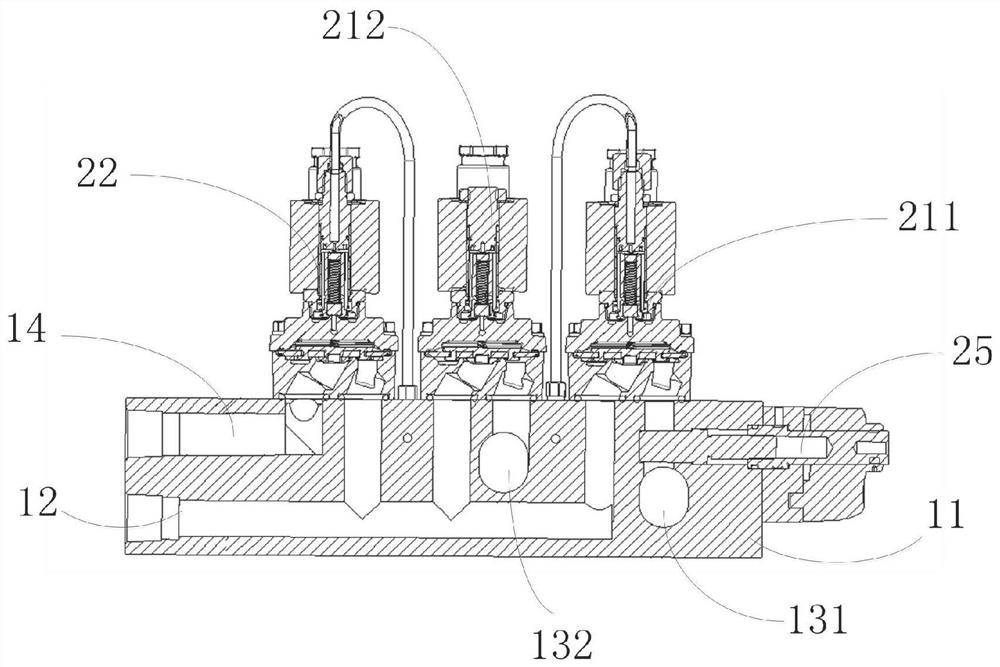

[0134] Please refer to Figure 12 , Figure 14 and Figure 15 , Figure 12 It is a perspective view of the third embodiment of the blow molding machine manifold of the present invention, Figure 14 It is a side view of the third embodiment of the blow molding machine manifold of the present invention, Figure 15 It is a cross-sectional schematic view of the internal structure of the third embodiment of the manifold for bottle blowing machine of the present invention.

[0135] The following is a blow molding machine manifold that can solve the above technical problems provided by the present invention, which is used to assemble the solenoid valves of the blow molding machine. Several solenoid valve groups include the first inlet valve group 61 and the first exhaust valve Group 62; wherein, the first air intake valve group 61 includes at least one air intake valve, used to control the input of gas in the mold cavity; the first exhaust valve group 62 includes at least one exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com