A composite beam

A technology of composite beams and beams, applied in the field of composite beams, can solve problems such as unsatisfactory, shear resistance of shear-resistant connectors cannot be fully utilized, shear-resistant connection fractures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

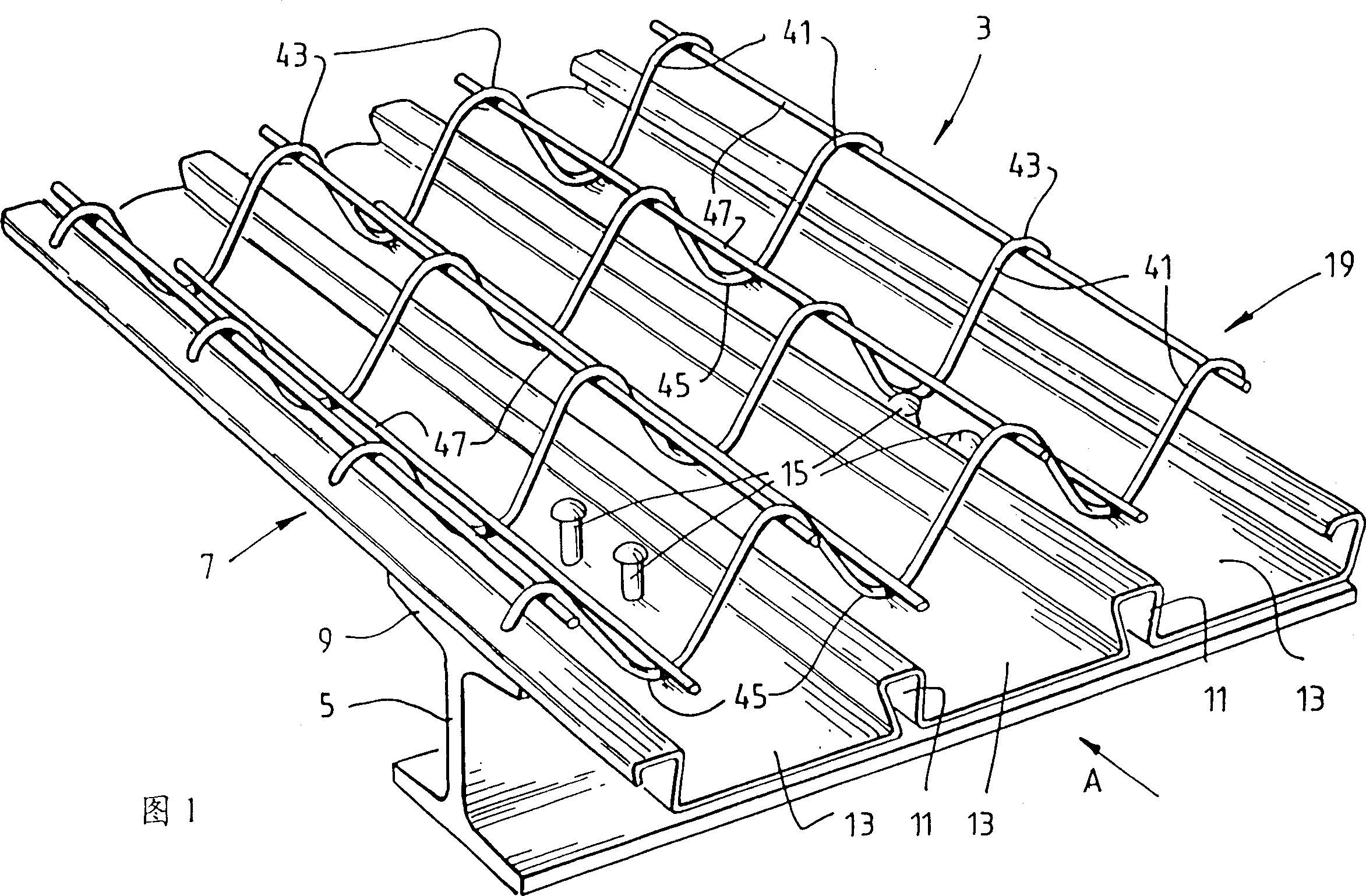

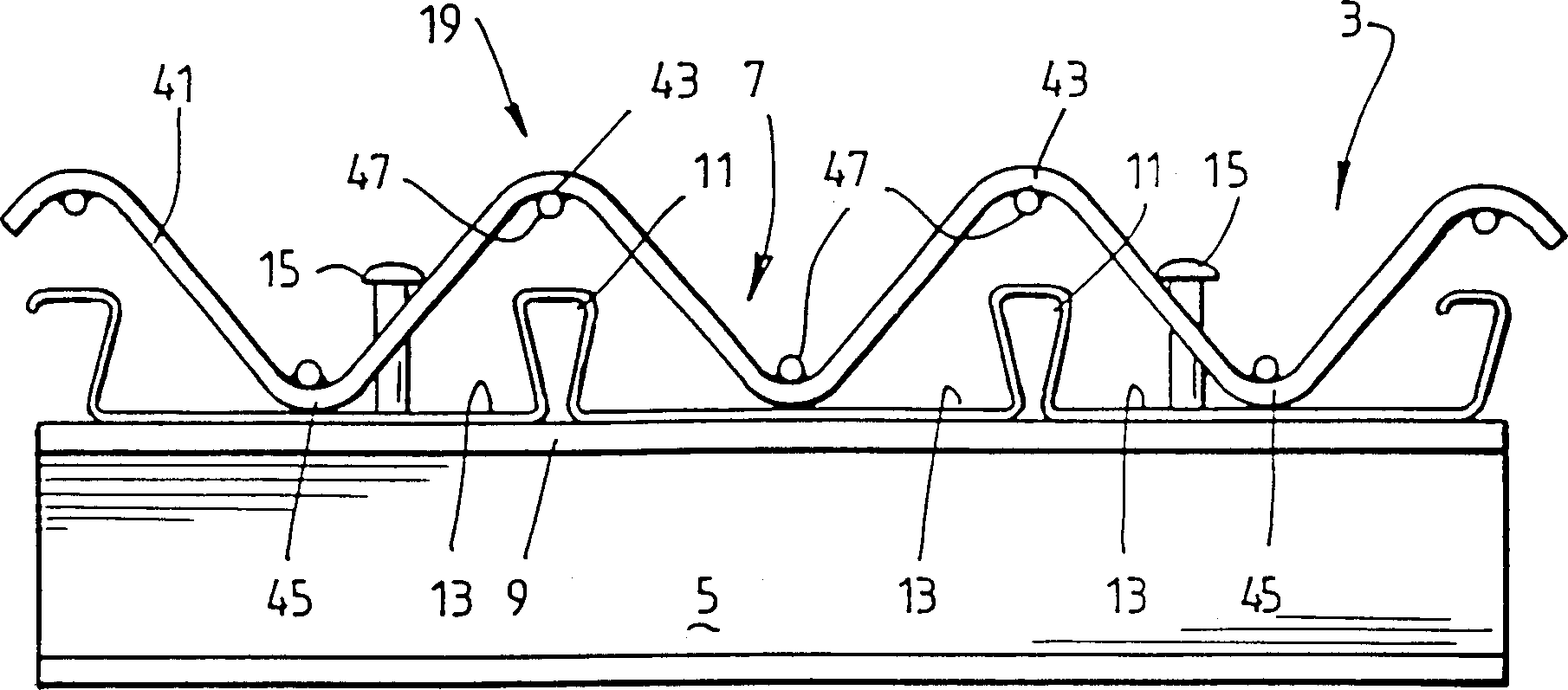

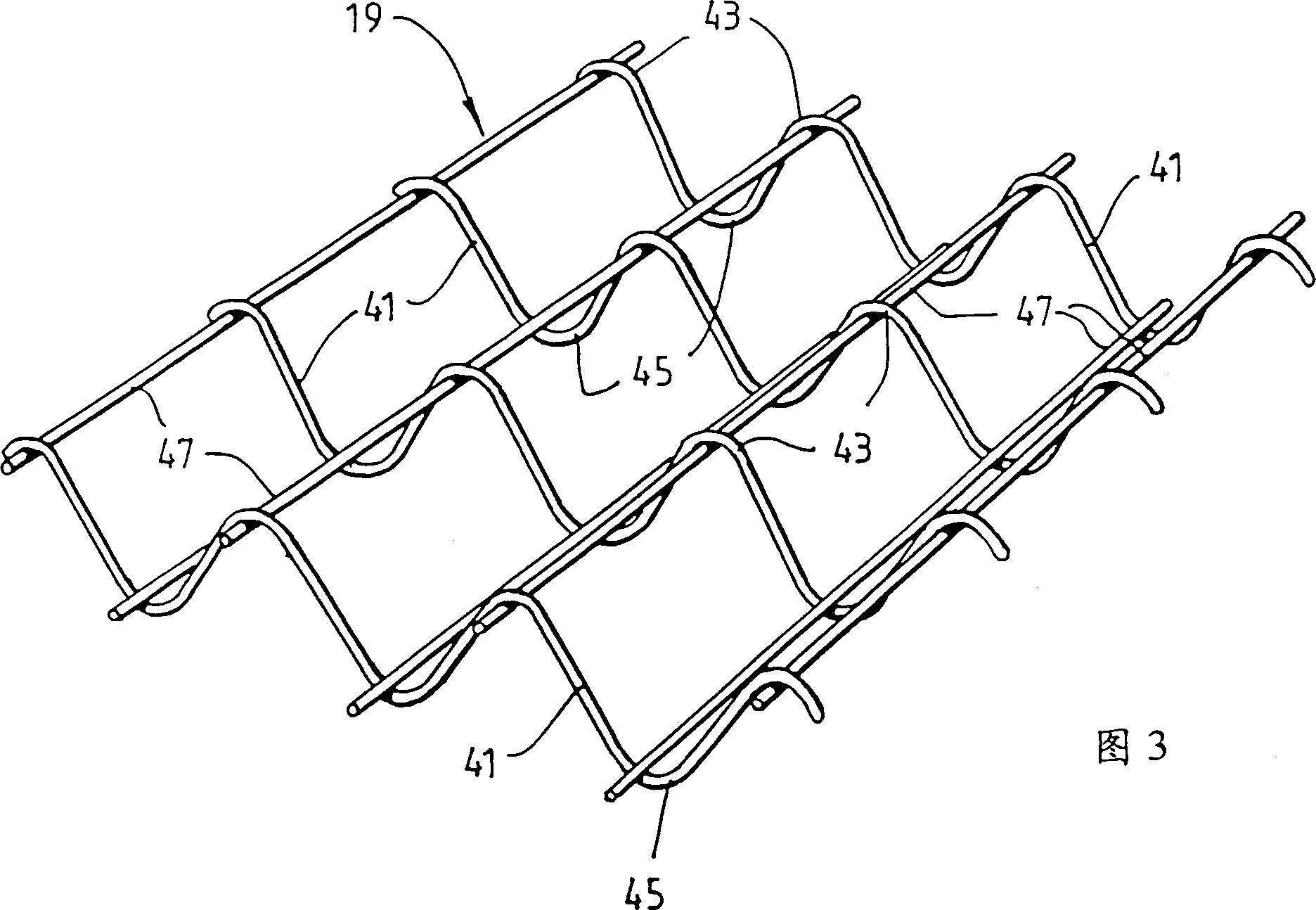

[0054] The preferred embodiment of the composite beam 3 of the present invention shown in FIGS. 1 to 3 illustrates the composite beam 3 more clearly in a simplified form.

[0055] With reference to accompanying drawing, the composition of composite beam 3 is:

[0056] (a) a horizontally extending hot-rolled or fabricated steel beam 5 supported at both ends;

[0057] (b) Composite panels, including:

[0058] (1) The shaped steel plate 7 that joins with the upper flange 9 of the steel girder 5, and the steel plate 7 includes many parallel arch bridges 11, separated by the flat part 13 between them, and the longitudinal direction of the arch bridge 11 relative to the steel girder 5 The axis is placed horizontally;

[0059] (II) concrete poured on the steel plate 7 (not shown);

[0060] (c) a number of shear connectors 15 in the form of braced studs passing through the steel plate 7 and welded to the upper flange 9 of the steel beam 5; and

[0061] (d) Reinforcement 19 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com