Limiting scraper type automatic discharging equipment and discharging method

An automatic discharge and scraper-type technology, applied in the direction of loading/unloading, conveyors, mechanical conveyors, etc., can solve the problems of large dust, poor working conditions, and low automation, and achieve simple control, improved efficiency, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

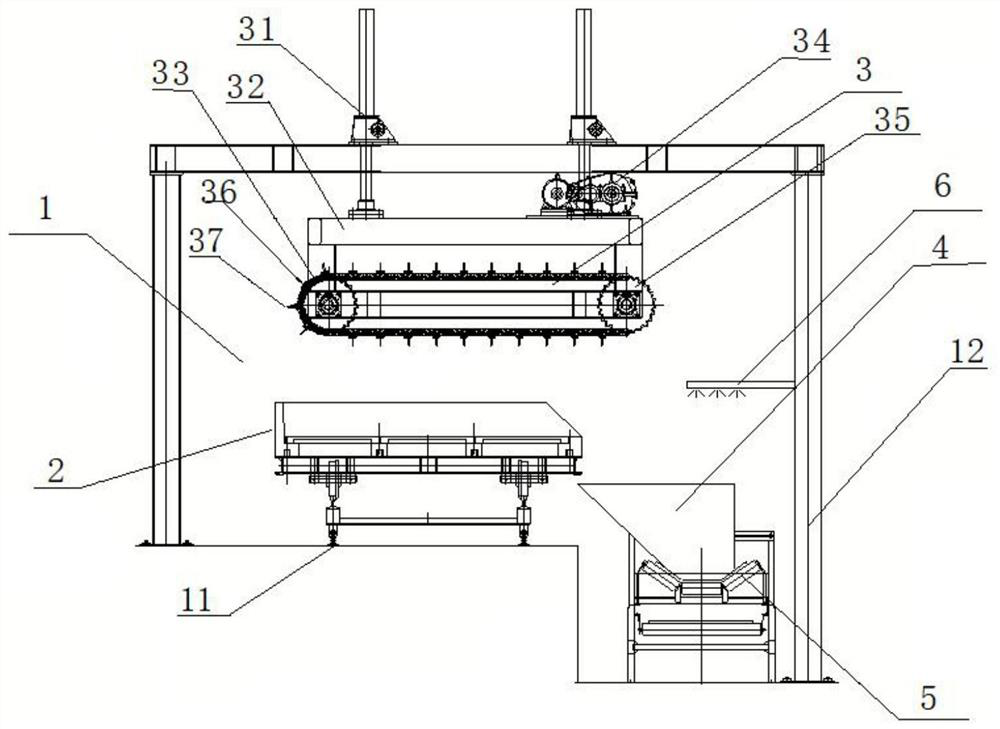

[0035] An embodiment of the present invention, such as figure 1 As shown, a limited scraper type automatic discharge equipment is disclosed, including a discharge bin 1, a loading trolley 2, a discharge unit 3, a receiving bucket 4, an ash conveying device 5 and a dust reduction device 6, which can realize the Quick unloading and cleaning in high temperature closed environment.

[0036] For illustrative purposes, figure 1 The left side of the direction shown is left, the right side is right, the direction with the horizontal plane up is up, and the direction with the horizontal plane down is down.

[0037] This embodiment is applied to the unloading of high-temperature powdery soil in the tunnel kiln soil restoration process. The unloading bin 1 is located at the end of the heat treatment section of the tunnel kiln. The unloading bin 1 is connected to the tunnel kiln body to ensure that the loading trolley 2 can run to the set position of the unloading bin 1 through the inne...

Embodiment 2

[0053] One embodiment of the present invention discloses a discharging method of a limit scraper type automatic discharging device, comprising the following steps:

[0054] S1. The loading trolley 2 enters the unloading bin 1:

[0055] A plurality of loading trolleys 2 are arranged in sequence in the tunnel kiln, and a propulsion mechanism is provided in the tunnel kiln. Driven by the propulsion mechanism, the loading trolleys 2 enter the unloading bin 1 along the loading trolley track 11, and the propulsion mechanism Each time the loading trolley 2 is pushed forward by the length of one loading trolley, the advancing frequency is 5-20min / time.

[0056] S2, unloading unit 3 starts and begins to descend:

[0057] A limit switch is provided at the position corresponding to the unloading unit 3 on the track 11 of the loading trolley. After the loading trolley 2 enters the corresponding position of the unloading bin 1, the limit switch is triggered, thereby starting the unloading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com