Waste filament treatment mechanism for filament covering machine

A technology for wrapping silk machine and waste silk, which is applied in textiles and paper making, etc., can solve the problems of low resource utilization rate, falling in, and waste silk cannot be reused, and achieves the effect of improving separation effect and dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-6 The application is described in further detail.

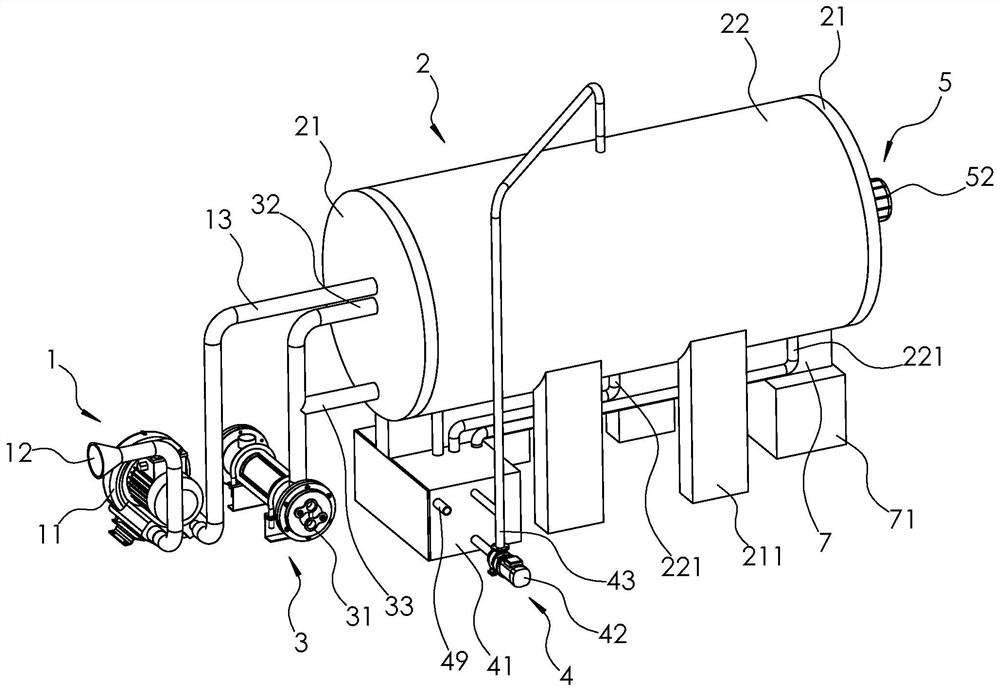

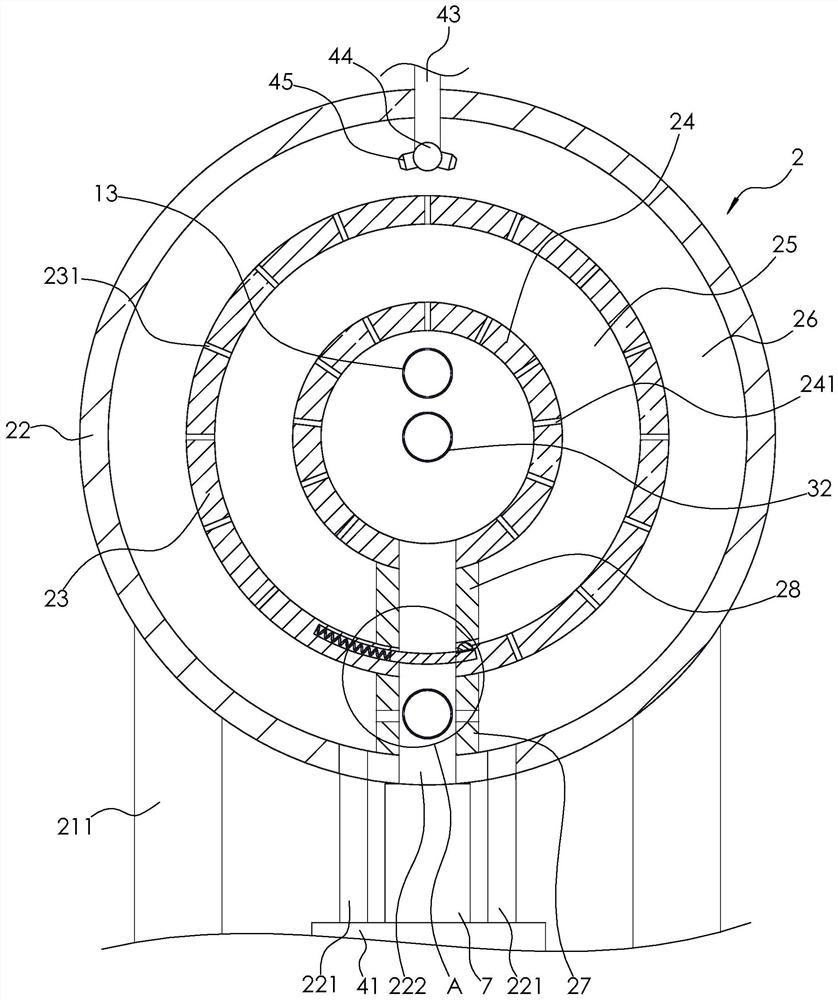

[0038] The embodiment of the present application discloses a waste silk processing mechanism of a covered silk machine. Such as figure 1 As shown, a waste silk processing mechanism of a covered silk machine includes a suction assembly 1, a separation assembly 2, an air jet assembly 3 and a spray assembly 4, and the suction assembly 1 is used to suck waste silk and dust into the separation In the assembly 2, the air jet assembly 3 is used to separate the waste silk and the dust in the separation assembly 2, and the spray assembly 4 is used to spray and remove the dust in the separation assembly 2.

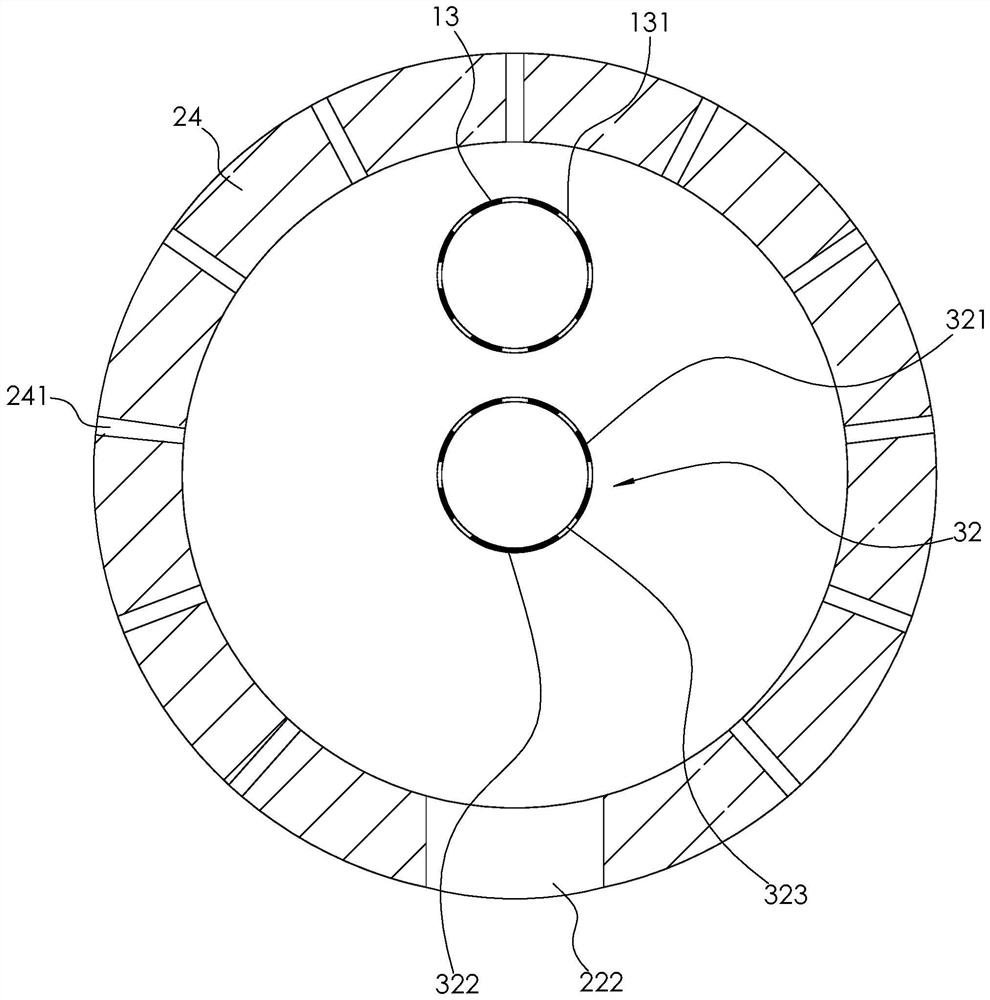

[0039] Such as figure 1 with figure 2 As shown, the separation assembly 2 includes two fixed plates 21 arranged in sequence along the horizontal direction, an outer cylinder 22 between the two fixed plates 21, an inner cylinder 23 and a rotating cylinder 24, and both ends of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com