Velvet fabric with high water absorption rate and low water retention rate and production method thereof

A technology of water retention and water absorption, applied in textiles, protective clothing, yarns, etc., can solve problems such as sticking to the body, bloated, uncomfortable, etc., and achieve the effect of low water retention and high water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0176] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

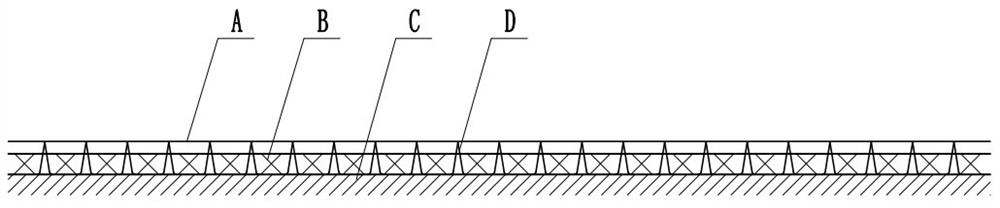

[0177] Such as figure 1 As shown, the velvet fabric layer A is connected to the velvet base cloth layer B through the bonding weaving method, and the suede warp of the velvet fluff layer C is consolidated on the velvet base cloth layer B through five wefts, protruding from the velvet base cloth The suede root D of the velvet fluff of the layer, and the other end is 1 / 4 of the velvet fluff layer C.

[0178] People put the velvet fluff layer C of this velvet sportswear fabric next to their skin, and the sweat generated by exercise is siphoned by the vertical spiral holes and spiral grooves in the close-fitting velvet fluff layer C to the velvet fluff that protrudes from the velvet base fabric layer. The fluff root D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com