Durable asphalt pavement and construction method thereof

An asphalt pavement and durability technology, applied in the field of durable asphalt pavement and its construction, can solve the problems of low resistance to vertical loads and stable loads, poor pavement durability, and large porosity, so as to reduce intrusion and improve Durability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

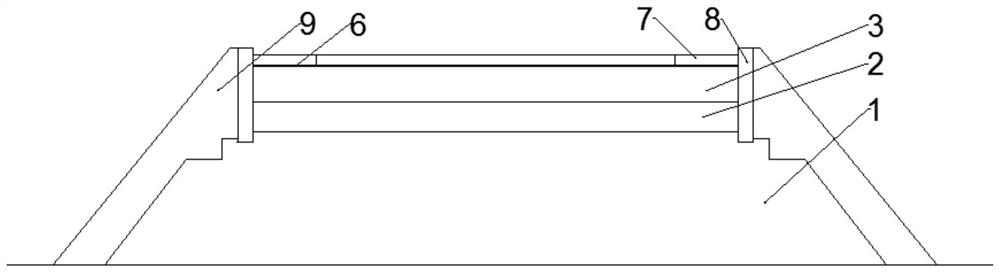

[0057] The construction method of durable asphalt pavement comprises the following steps:

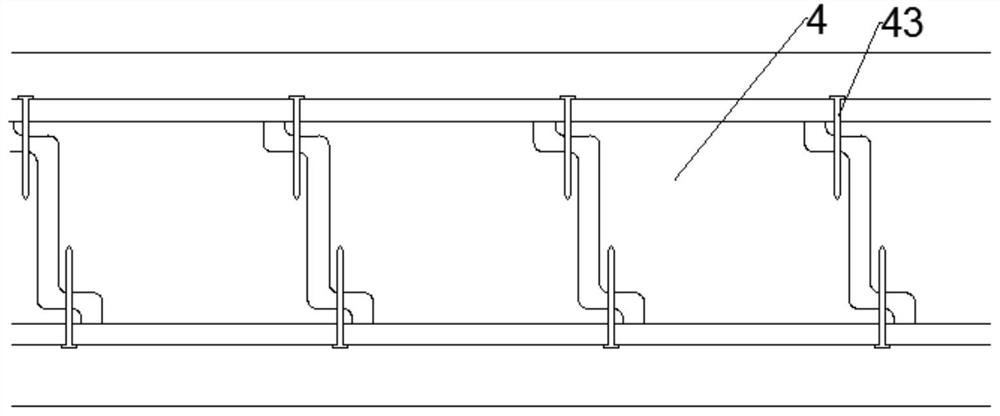

[0058] S1, making the prefabricated panel unit 4 and tenons;

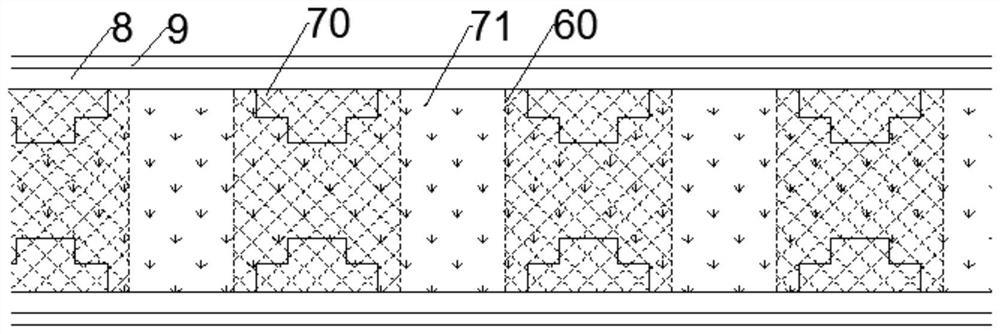

[0059] Pouring lean concrete into the mold, rolling the lean concrete and roughening the surface, leaving it for curing, demoulding after curing, and continuing curing after demoulding to obtain the base layer 40;

[0060] Install a mold on the upper surface of the base layer 40, spray asphalt binder on the upper surface of the inner base layer 40 in the mold, then spread the graded large particle size asphalt mixture, roll and stand to obtain the top layer 41, and complete the production of the prefabricated panel unit 4 ;

[0061] Pour cement concrete into the mold to obtain health;

[0062] S2. Excavating side slopes on both sides of the soil foundation 1 along the width direction;

[0063] S3. Pave the soil foundation 1 according to the current technical standards to achieve a stable foundation. The paving of the soil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com