Multi-cavity steel plate-concrete composite shear wall and assembling method thereof

A technology combining shear walls and assembly methods, which is applied in the direction of walls, building components, buildings, etc., can solve the problems that the panels on both sides of the wall cannot form enough operating space, the thickness of the wall is limited, and the process is complicated, etc., and the construction method is simple Effective, high-quality production, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

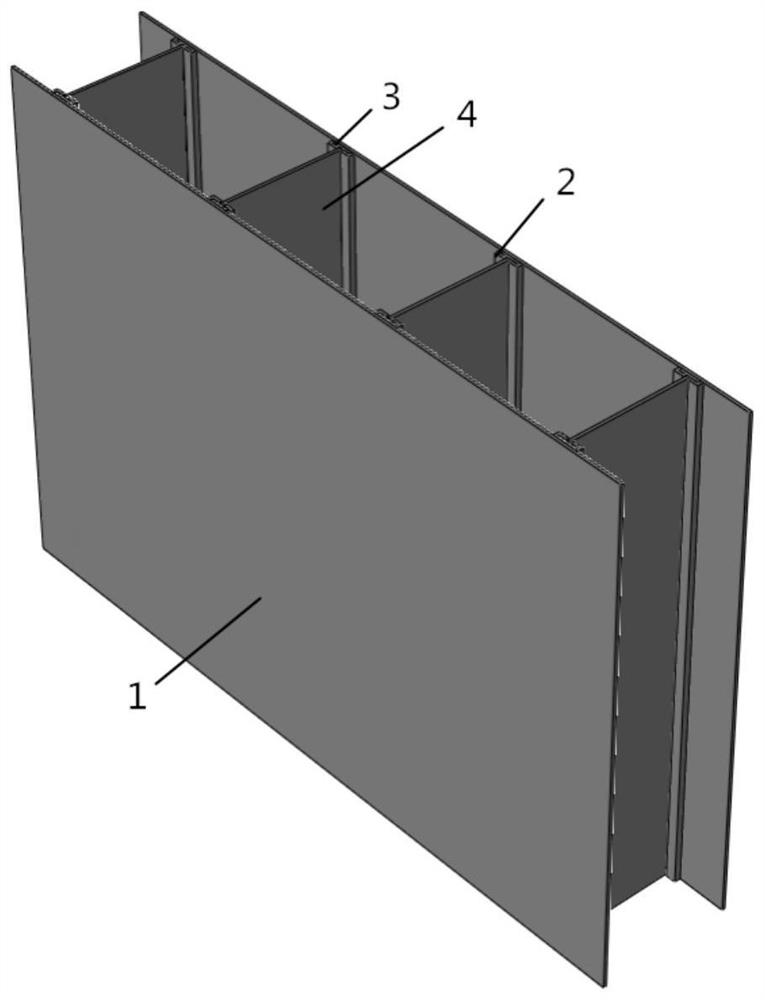

[0037] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of multi-cavity steel plate-concrete composite shear wall described in this embodiment, it comprises two panels 1, two panels 1 are arranged relatively parallel, described multi-cavity steel plate-concrete composite shear wall also It includes a plurality of rib plate assemblies, the inner surfaces of the two panels 1 are connected by a plurality of said rib plate assemblies, and the multiple rib plate assemblies are arranged at equal intervals along the length direction of the panel 1 .

specific Embodiment approach 2

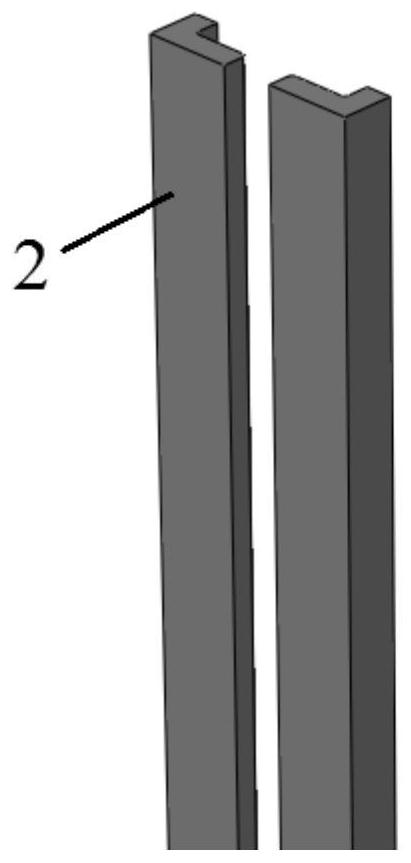

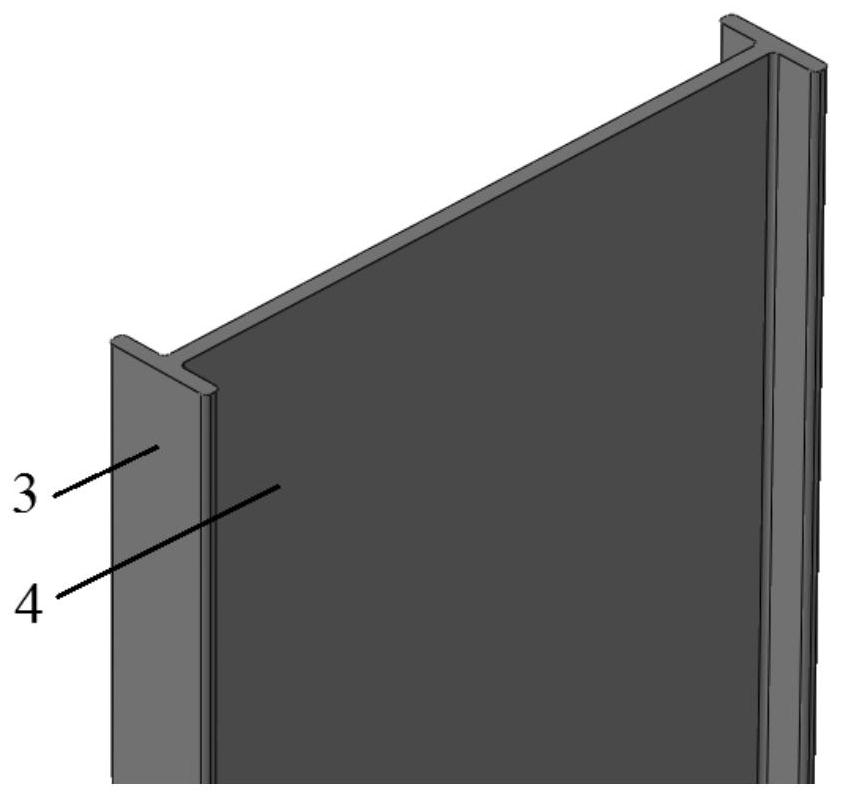

[0038] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, each rib assembly described in this embodiment includes four double-angle steels 2, two rib flanges 3 and rib webs 4, and every two double-angle steels 2 are arranged oppositely, and are respectively installed on two The inner side wall of a panel 1, a notch is formed between two double angle steels 2, and the rib flange 3 is inserted into a corresponding notch, and the rib web 4 is located between the two rib flanges 3 and is connected with the rib flange 3. The rib flange 3 is welded.

[0039] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 2 This embodiment will be described. The double-angle steel 2 in this embodiment is an "L"-shaped steel plate.

[0041] Other components are the same as those in the second embodiment in terms of connections.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com