A pressure-relieving method of impulse roof cutting in gob-side roadway

A roof cutting pressure relief and roadway technology, which is used in tunnels, earthwork drilling, tunnel lining and other directions, can solve the problems of easy deviation of test orientation, inaccurate test data, slow roof cutting speed, etc., and the number of repeated operations can be controlled. , Improve the repair effect, the effect of small power disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

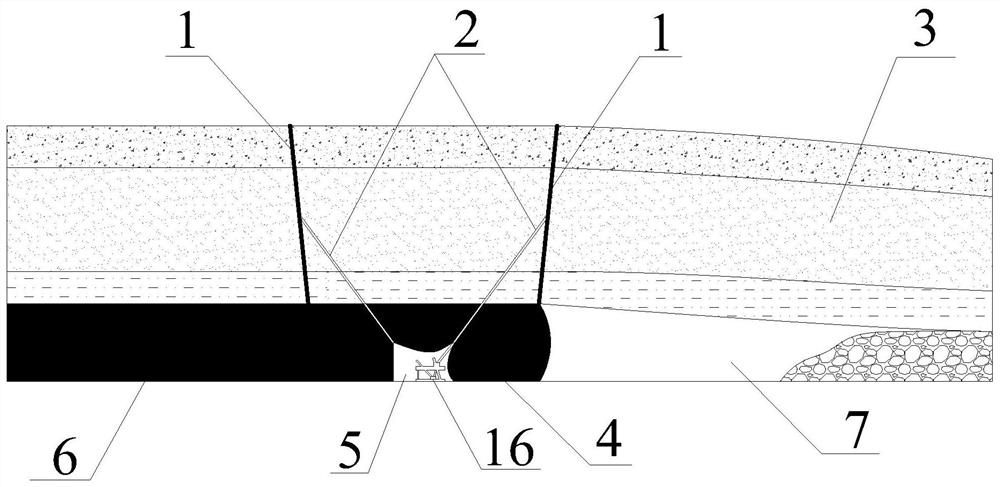

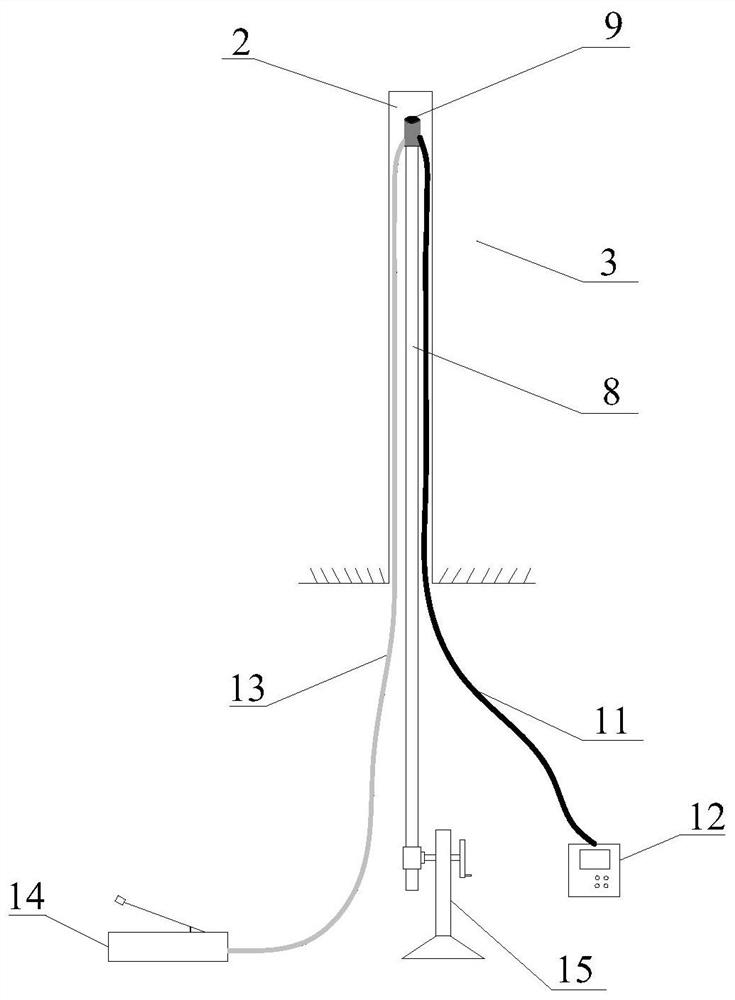

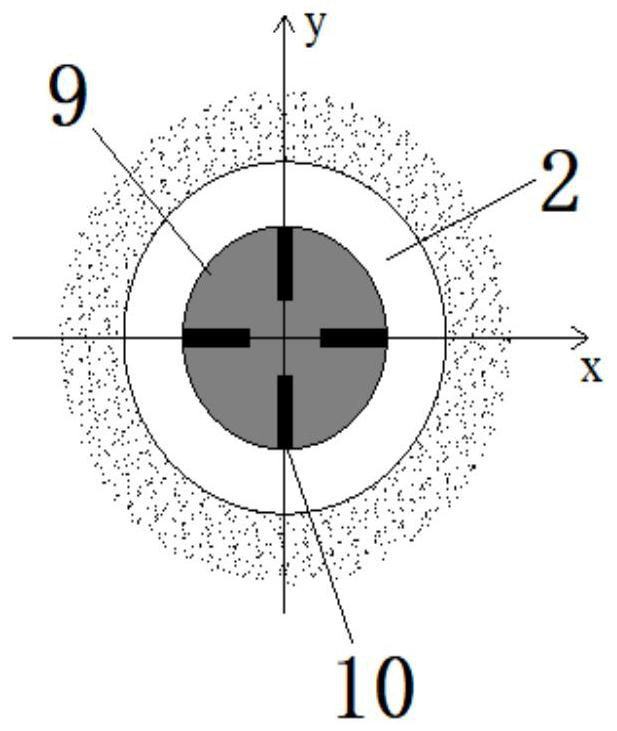

[0035] The present invention is further described below with reference to the drawings:

[0036] like Figure 1 to 12 As shown, a method of removing a cutting pressure along a pulse pulse of the empty lane, including a drilling touch device and an electrical pulse device 16 including a conveying rod 8, a lifter 15, a probe 9, a probe The needle 10, the hand pressing pump 14 and the data acquisullerator 12, the transport rod 8 is a telescopic rod member, and the lower end of the conveying rod 8 is connected to the lifter 15, and the outer diameter is less than the inner diameter of the drilling 2; the riser 15 The fixed mounted is within the empty roadway 5, the elevator 15 is a can be lifted, and the pitch angle can be adjusted, but can also adjust the depth of the conveying rod 8 into the drilling 2, but also adjust the angle of the transport rod 8 to accommodate different angles. The drilling 2, which in turn can be implemented in flexible control of the transport rod 8; the prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com