Transmission shaft electric actuator with brake assembly

A technology of brake components and electric devices, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of high cost, small braking force, poor braking effect, etc., to prolong life, meet the needs of braking, and save use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] see Figure 1-Figure 6 , a transmission shaft electric device with a brake assembly, comprising a reducer 3, an electric motor 2, a control panel 1 and a brake assembly 4, the output shaft of the electric motor 2 is fixedly connected to the output shaft of the reducer 3, the The control board 1 is electrically connected with the electric motor 2 , the output shaft of the reducer 3 is inserted into the brake assembly 4 , and the brake assembly 4 is arranged at the low speed end of the reducer 3 .

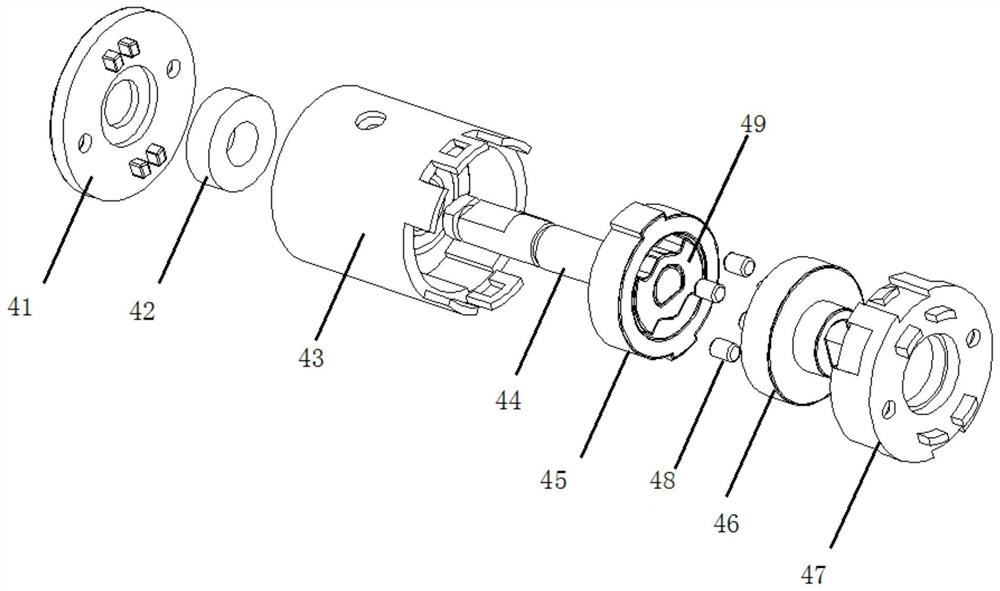

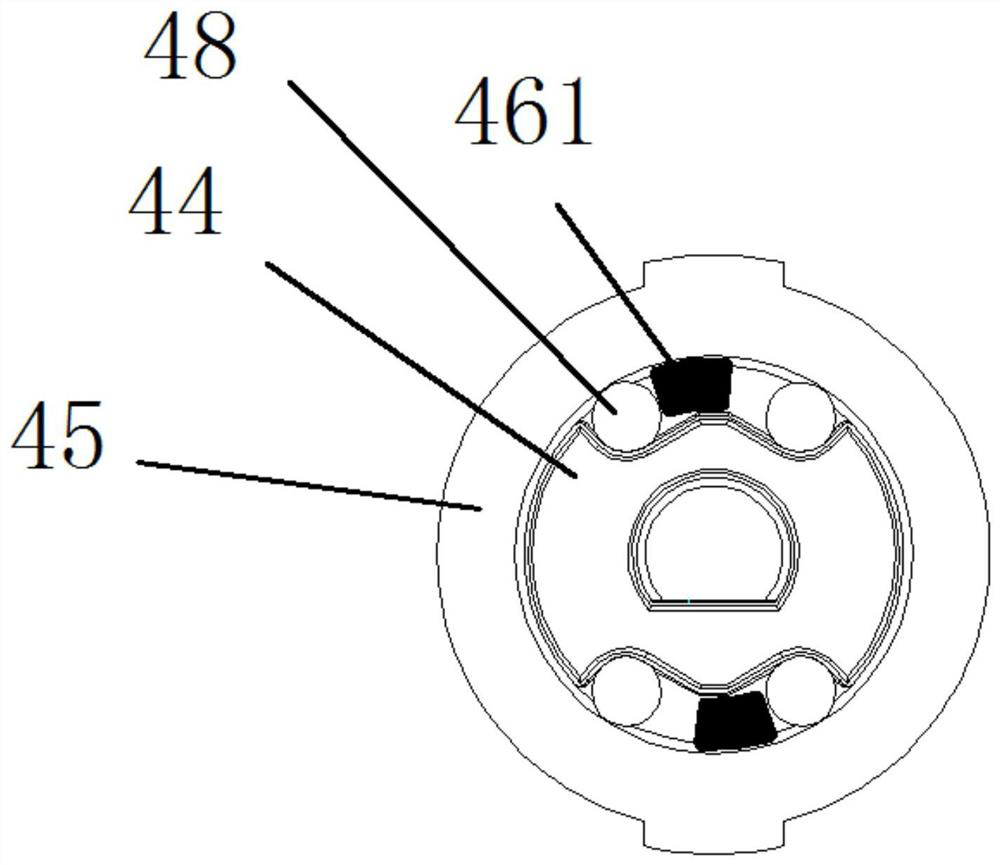

[0025] As an improvement of the above scheme, the brake assembly 4 includes a housing 43, an end cover 41, a cover plate 47, a fixed plate 45, a driven member 49, a transmission shaft 44, a driving member 46 and a roller 48, and the housing 43 and The reducer 3 is fixedly connected, the end cover 41 is arranged on the end of the casing 43 away from the reducer 3 , the cover plate 47 is arranged on the end of the casing 43 close to the reducer 3 , and the fixing plate 45 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com