Torque suction and discharge device based on elastic pin mechanism

A technology of spring needle and needle tip, applied in spring/shock absorber, mechanical equipment, vibration suppression adjustment, etc., can solve the problems of increased precision and production cost, reduced reliability, etc., to solve the problem of torque vibration, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

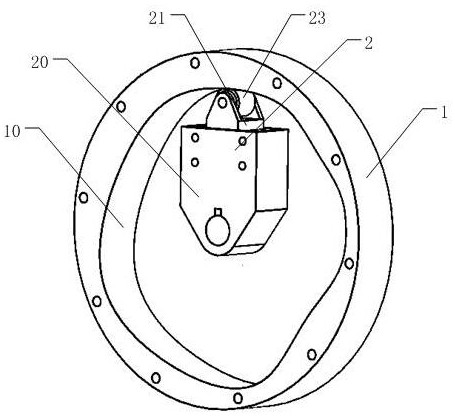

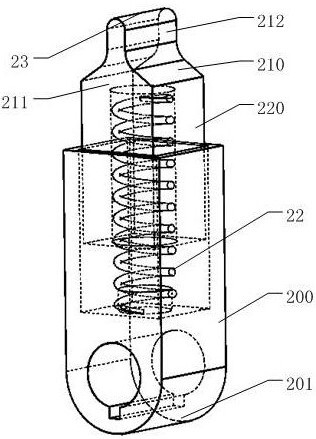

[0087] Such as figure 2 Shown is the radial sliding-cylindrical surface sliding fixed movable support pin, the movable support tail 210 is a fixed upright wall 211 with the cylinder as the top surface, and the generatrix of the cylinder is parallel to the main shaft axis of the movable support, wherein the fixed vertical Anti-falling walls or reinforcing ribs can also be added on both sides of the wall 211 . The fixed upright wall 211 and its reinforcing ribs are fixed on the movable support base 212, or are integrated with the movable support base 212. During work, the cylindrical surface is in sliding contact with the track surface 10, and the cylindrical surface is fixed relative to the movable support bottom 212.

Embodiment 2

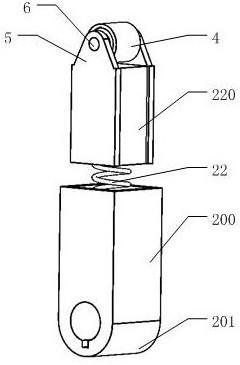

[0089] Such as image 3 and Figure 4 Shown are the radial sliding-cylindrical rolling fixed support spring pin and the radial fixed support side bearing rolling-cylindrical rolling fixed support spring pin respectively. The dynamic support tail 210 of this type of spring pin is composed of a top bearing 4, Two top bearing pedestals 5 and a top bearing shaft 6 are formed. The outer surface of the top bearing 4 is a cylindrical surface, the top bearing shaft 6 is fixed, and the top bearing shaft frame 5 is fixed on the bottom 212 of the movable support or is integrated with the bottom 212 of the movable support. The generatrix of the outer cylindrical surface of the top bearing 4 is parallel to the main shaft axis of the bullet pin. During work, the cylindrical surface of the top bearing 4 is in rolling contact with the track surface 10, and is fixed relative to the bottom 212 of the movable support.

Embodiment 3

[0091] Such as Figure 5 and Figure 6 Shown are a single top bearing moving bracket and a composite jacking bearing moving bracket respectively. The moving bracket tail 210 of this type of moving bracket 21 is composed of a top bearing 4 , two top bearing shaft frames 5 and a top bearing shaft 6 . The top bearing shaft 6 is fixed, the axis of the top bearing shaft 6 is parallel to the axis of the main shaft, and the top bearing shaft frame 5 is fixed on the movable support bottom 212 or integrated with the movable support bottom 212, which is parallel and symmetrical to the spring needle 2 Two upright walls passing through the center line of the compression spring 22 and perpendicular to the plane (the first symmetry plane of the spring pin) of the axis of the main shaft. The top bearing pedestal 5 can also have two upright walls that are parallel and symmetrical to the plane (the second symmetry plane of the pin) that the pin 2 passes through the center line of the clip spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com