Aperture size measuring device and measuring method

The technology of a measuring device and a measuring method, which is applied in the direction of mechanical diameter measurement, etc., can solve the problems of prone to errors in measurement, complicated operation process, and difficulty in meeting measurement needs, etc., and achieves improved measurement efficiency, quick disassembly, strong versatility and practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

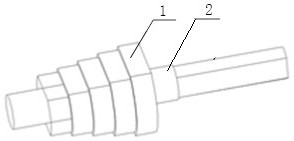

[0027] The present invention is an aperture size measuring device, comprising a measuring block 1 and a measuring rod 2, the rear part of the measuring rod 2 is a handle 3, the middle part of the measuring rod 2 is provided with threads, and at least three measuring blocks 1 are fixed on the measuring rods through threads; The outer diameter of the measuring block is distributed according to the tolerance steps of the hole 4 to be measured, and increases sequentially from the front end to the rear.

[0028] The outer diameter of the measuring block is distributed according to the tolerance of the measured aperture.

[0029] Example 1

[0030] The present invention is an aperture size measuring device, comprising a measuring block 1 and a measuring rod 2, the rear part of the measuring rod 2 is a handle 3, the middle part of the measuring rod 2 is provided with threads, and at least three measuring blocks 1 are fixed on the measuring rods through threads; The outer diameter of...

Embodiment 3

[0032] A method for measuring the aperture size of the present invention, at first according to the size of the aperture of the measured hole 4 of the part The size of the measured hole and the accuracy requirements of the measured hole 4, the tolerance of the measured hole is divided into n equal parts according to the measurement accuracy, and then the size of the preparation is , , ··· , n measuring blocks, and finally install the measuring blocks on the measuring rod in order. When in use, you only need to put the measuring tool into the hole of the part to be measured, and find the measuring block that just fits the hole to be measured. Measure the size of the hole.

[0033] The measuring block 1 and the measuring rod 2 that can be installed with measuring blocks of various sizes can be assembled on the measuring rod through threaded connection, so as to measure the hole to be measured corresponding to the hole diameter of the measuring block 2 .

[0034] Measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com