A force-transfer type anti-bending cable

An anti-bending and transfer-type technology, applied in the direction of bendable cables, insulated cables, cables, etc., can solve problems such as cable damage, safety hazards, aging, etc., to suppress deformation, reduce safety hazards, and improve bending resistance effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

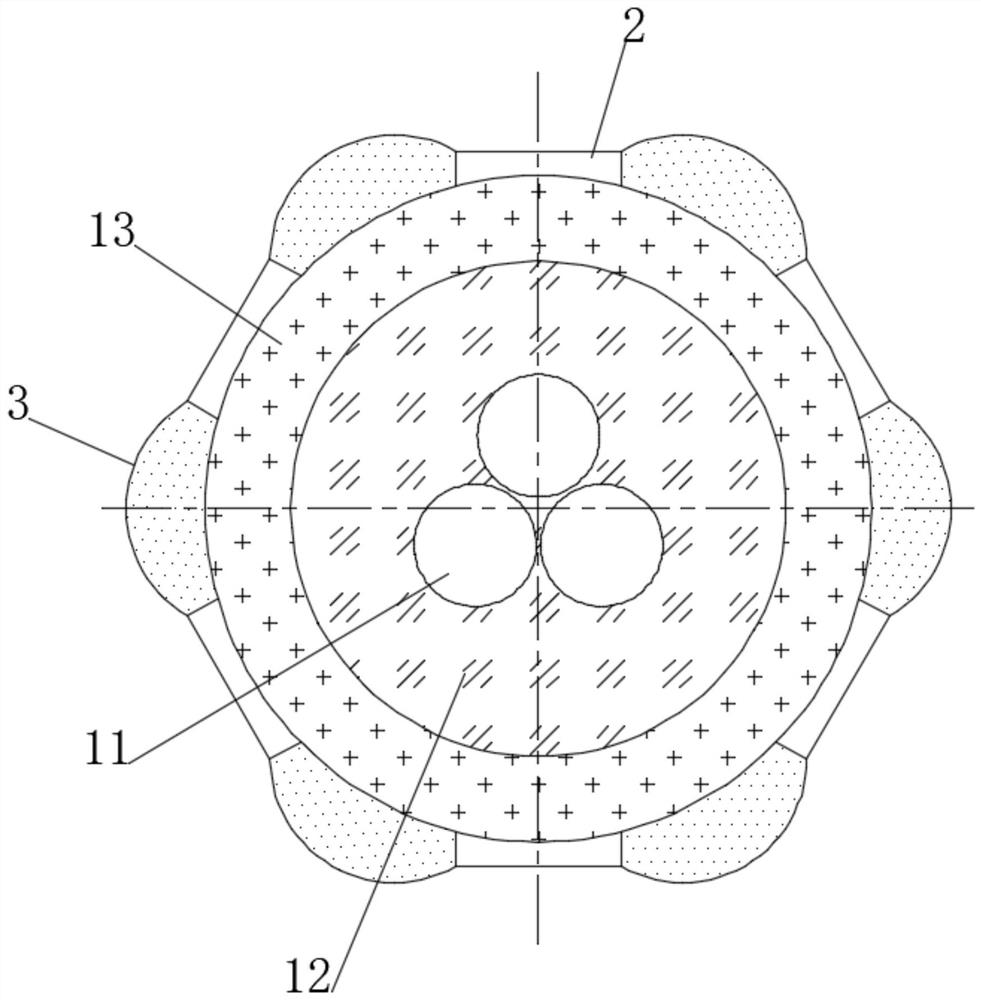

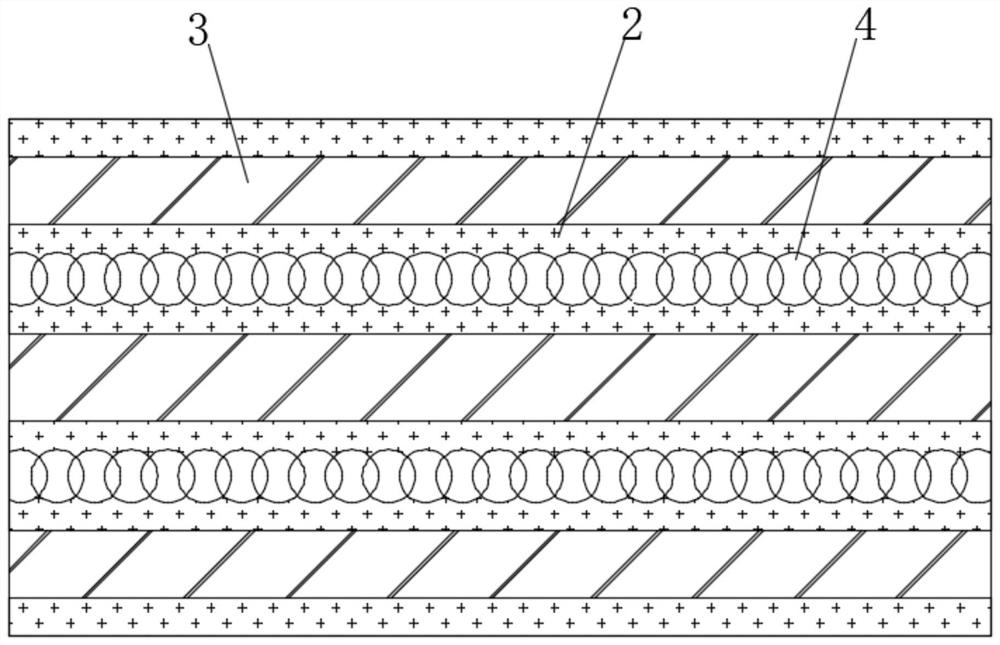

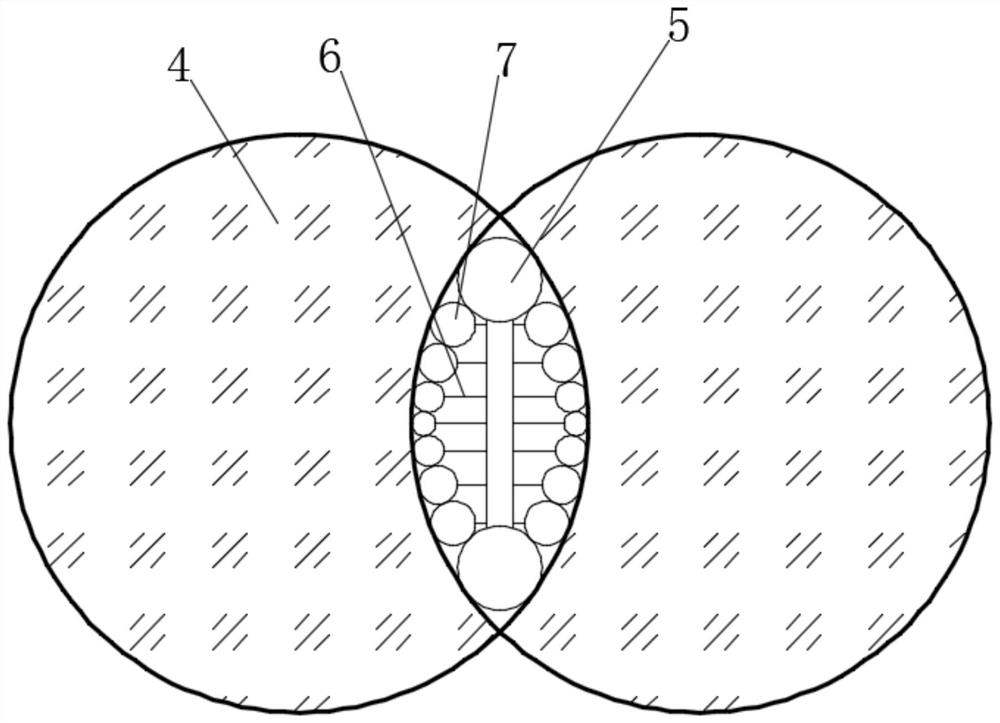

[0039] see Figure 1-2 , a force transfer type anti-bending cable, including a core layer 11, an insulating layer 12 wrapped outside the core layer 11, and an outer sheath layer 13 wrapped outside the insulating layer 12, and the outer end of the outer sheath layer 13 is fixedly connected There are a plurality of evenly distributed anti-folding strips 2, and anti-folding ball chains are inlaid inside the anti-folding strips 2. The anti-folding ball chains include a plurality of embedded balls 4, and the outer end of the outer sheath layer 13 is fixedly connected with a plurality of evenly distributed The force transfer bar 3, a plurality of force transfer bars 3 and the anti-folding bar 2 are distributed alternately, and the anti-folding bar 2 and the force transfer bar 3 are fixedly connected, the force transfer bar 3 is a raised arc surface structure, and the end surface of the anti-folding bar 2 is Straight structure, and the vertex of the force transfer strip 3 is higher t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com