Heating curing device for transformer production

A heat curing and transformer technology, applied in the direction of inductance/transformer/magnet manufacturing, encapsulation/impregnation, electrical components, etc., can solve potential safety hazards in substation operation, deterioration of transformer relay power and conduction, and coil compaction Insufficient and other problems, to achieve the effect of improving heating and curing progressive regulation and packaging operation, protection conduction rate and anti-fuse operation, and ensuring convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

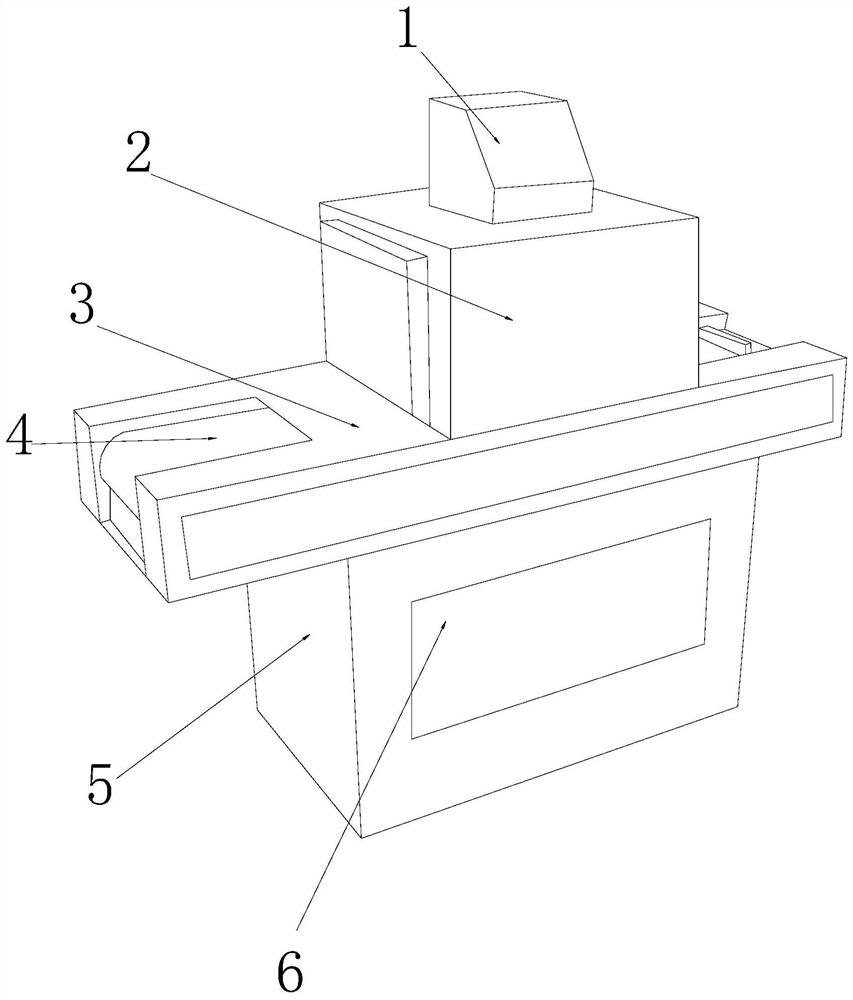

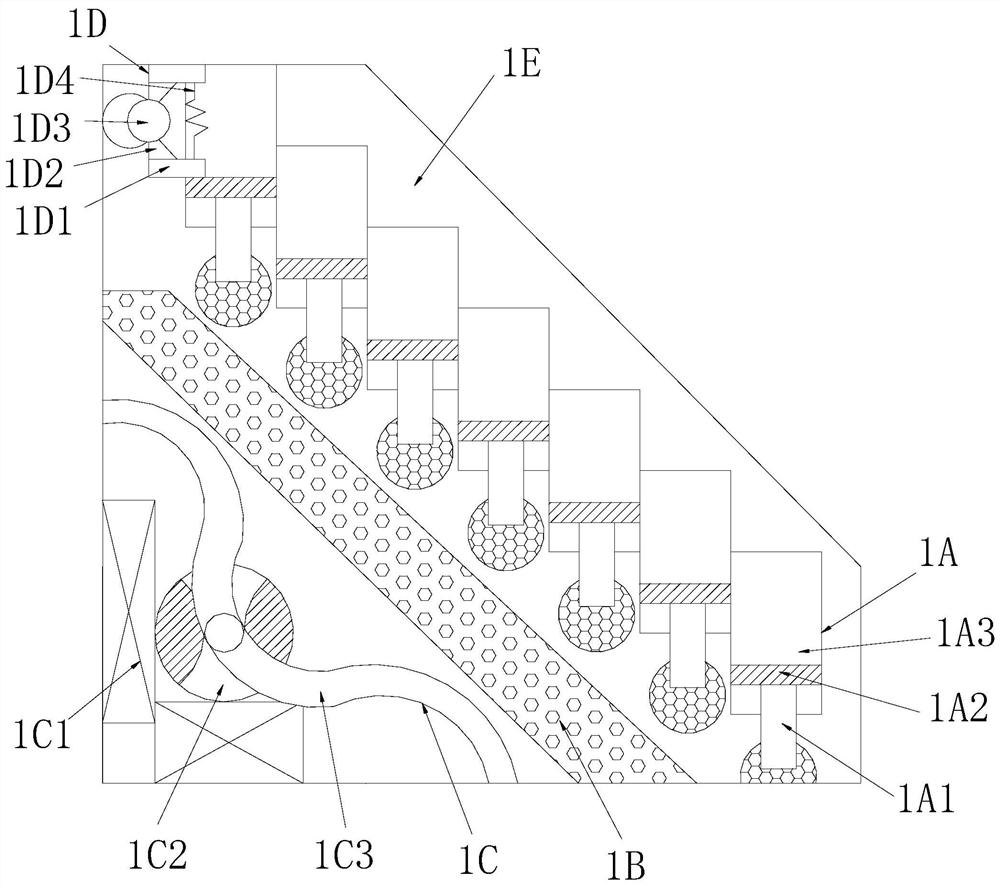

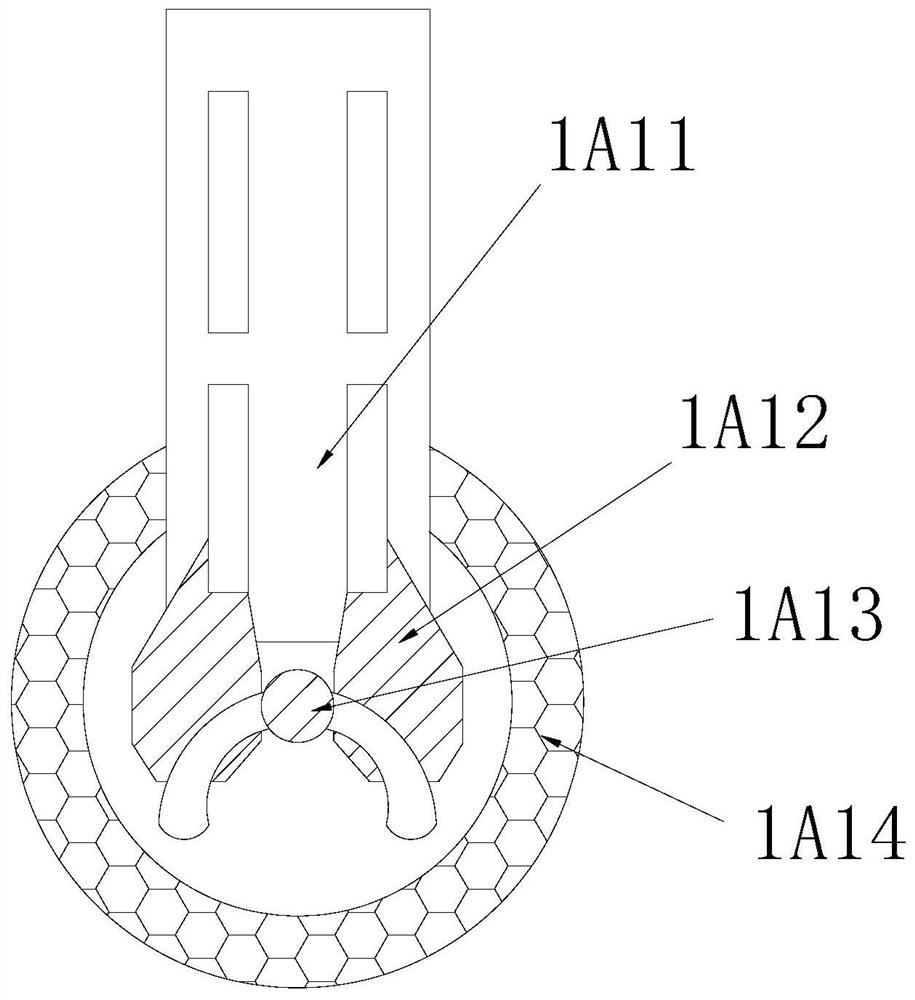

[0032] see Figure 1-Figure 6, the present invention provides a heating and curing device for transformer production, the structure of which includes: a gradient thermosetting top seat 1, an assembly box groove 2, a transmission shell platen 3, a transmission belt 4, a motor base box 5, and an electric control integrated board 6. The gradient thermosetting top seat 1 is nested on the top of the assembly box groove 2 and penetrates each other. The assembly box groove 2 is fastened together with the transmission shell platen 3 and is perpendicular to each other. The transmission belt 4 is inserted into the transmission shell The inside of the platform 3 is on the same horizontal plane. The transmission shell platform 3 is nested on the top of the motor base box 5. The electric control integrated board 6 is close to the front side of the motor base box 5 and is on the same vertical plane. On the straight side, the motor base box 5 is electrically connected to the transmission bel...

Embodiment 2

[0038] see Figure 1-Figure 6 , the present invention provides a heating and curing device for transformer production, other aspects are the same as in Embodiment 1, the difference is:

[0039] see figure 2 , the side roof retracting seat 1D is composed of a chute load-bearing block 1D1, an ear plate 1D2, a double-wheel distraction frame 1D3, and a spring wire 1D4. The chute load-bearing block 1D1 and the ear plate 1D2 are welded into one body, and the ear plate 1D2 is mechanically connected to the double-wheel distraction frame 1D3, and the chute load-bearing block 1D1 is mechanically connected to the spring wire 1D4 and is perpendicular to each other. Through the chute load-bearing block 1D1 along the double-wheel retraction frame 1D3, a unilateral limit-to-top clamp is formed. The effect of pressure adaptation adjustment ensures that the gradient reciprocating line distance is consistent and avoids excessive top pressure operation, and improves the uniformity of gradient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com