Hybrid module comprising a input shaft having a rotary union, and actuation unit for one of multiple clutches, and drive train

A hybrid power module and powertrain technology, which is applied to the layout of multiple different prime movers of general power plants, power plants, hybrid vehicles, etc., can solve the problem of high manufacturing and installation costs of separation clutches and the functional problems of hybrid power modules. Or the impact of service life and other issues, to achieve the effect of flexible rotary joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

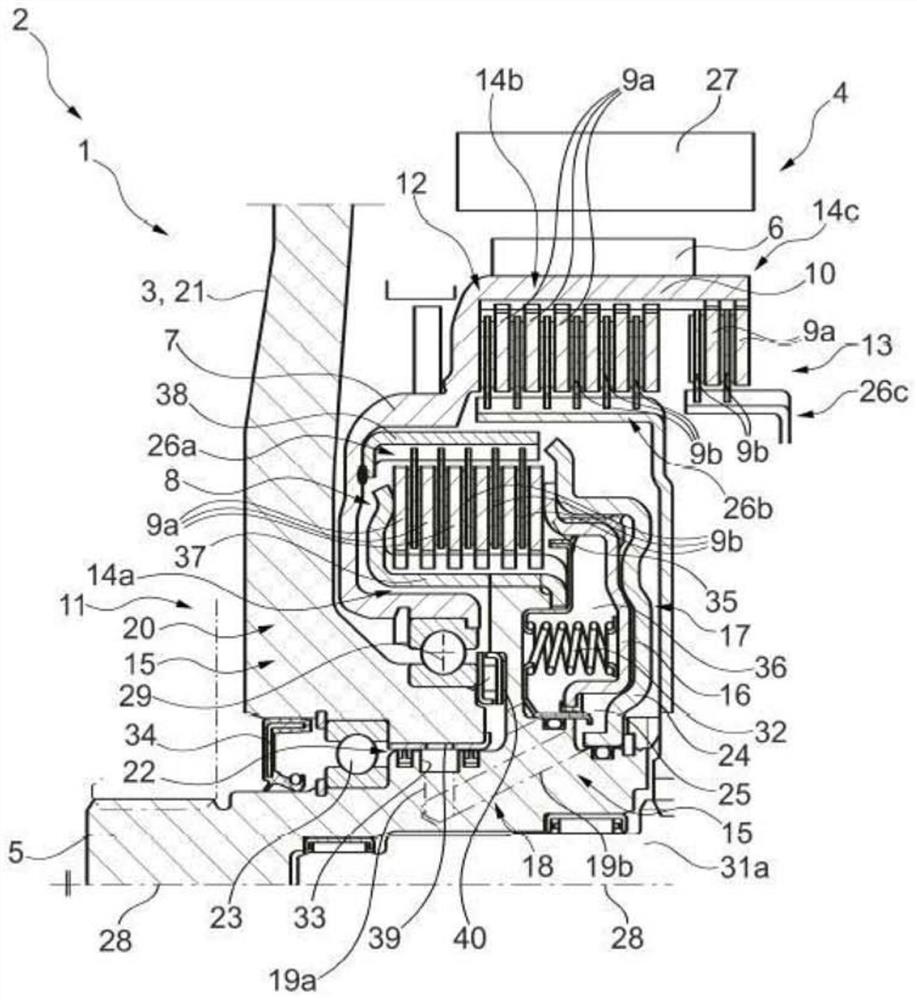

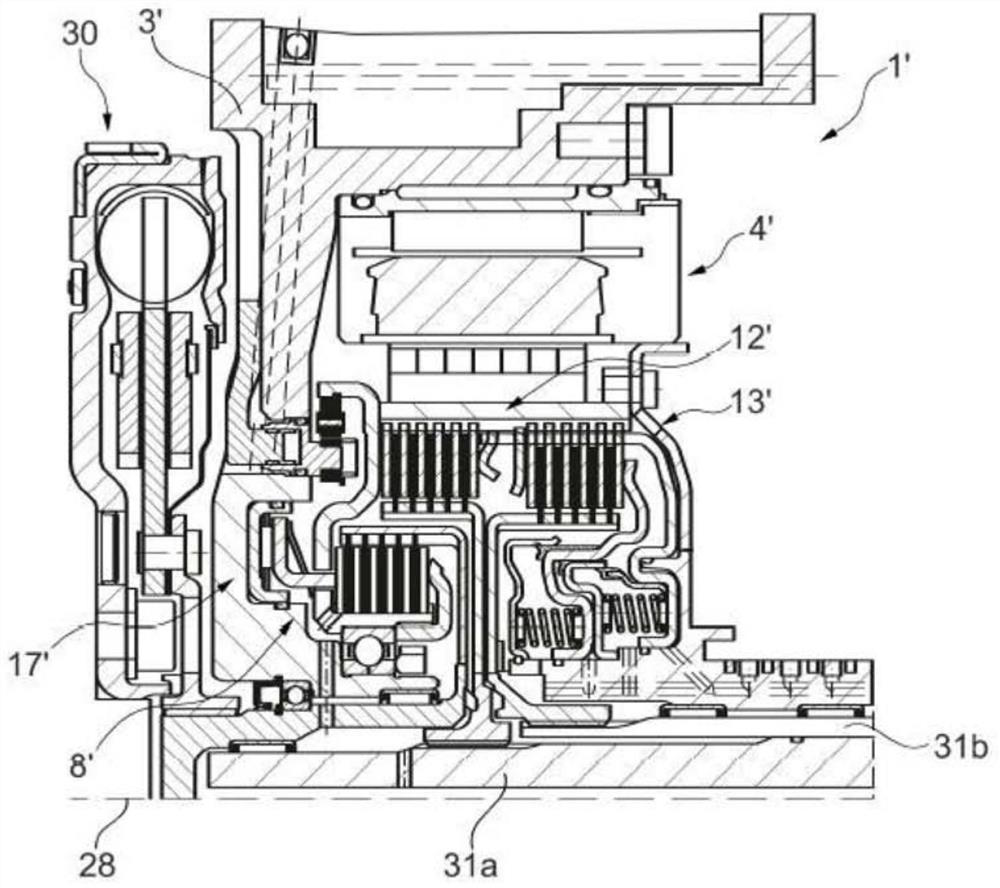

[0023] The drawings are merely schematic in nature and are used only to aid in the understanding of the invention.

[0024] figure 1 A hybrid module 1 according to a preferred embodiment of the invention is shown. exist figure 2 In can be seen a complete, known through the background technology and its principle structure conforms to figure 1 The hybrid module 1' of the hybrid module 1 is shown. In particular, it should be pointed out that figure 1 Details not shown in detail with respect to the two partial clutches 12, 13 and their operation can be obtained from, for example, the figure 1 of the illustrated embodiment figure 2 Learned from.

[0025] Accordingly, the hybrid module 1 according to the invention has a housing 3 in which an electric motor 4 is arranged. The electric machine 4 of the hybrid module 1 has a stator 27 which is firmly connected to the housing 3 and a rotor 6 which is rotatable relative to the stator 27 . In this embodiment, the rotor rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com