Heat extraction assembly for a semiconductor power module

A technology of power modules and thermal components, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as increased resistance and thermal resistance, reduced functionality, and reduced soldering connection area , to achieve the effect of eliminating power loss, good thermal conductivity, and low mechanical tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

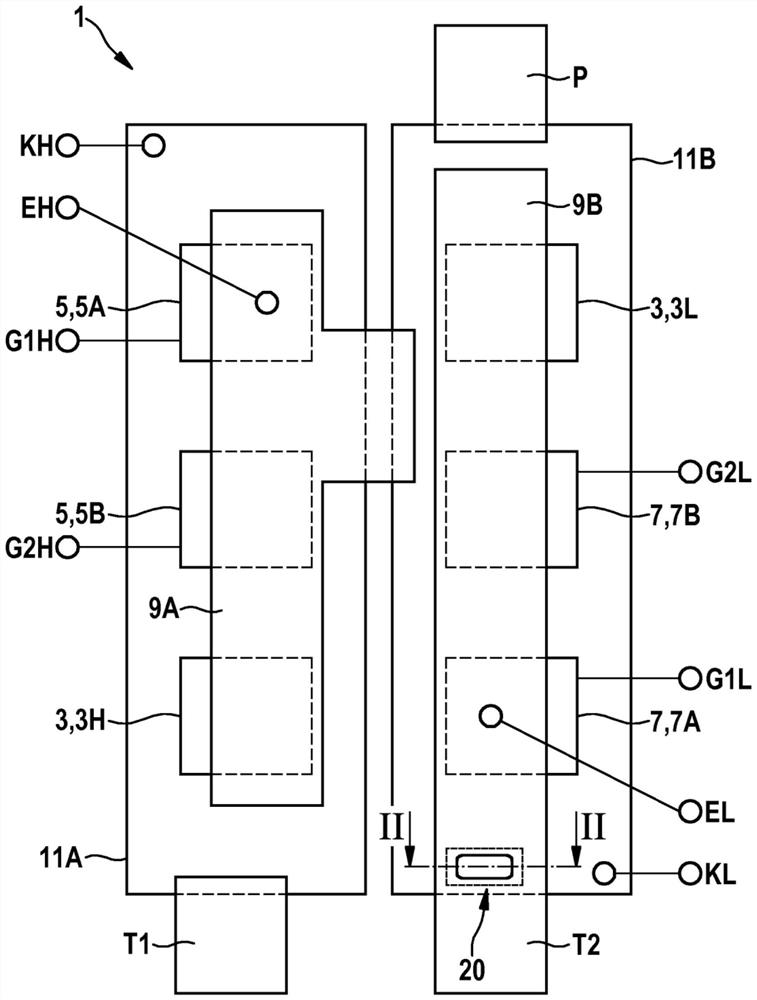

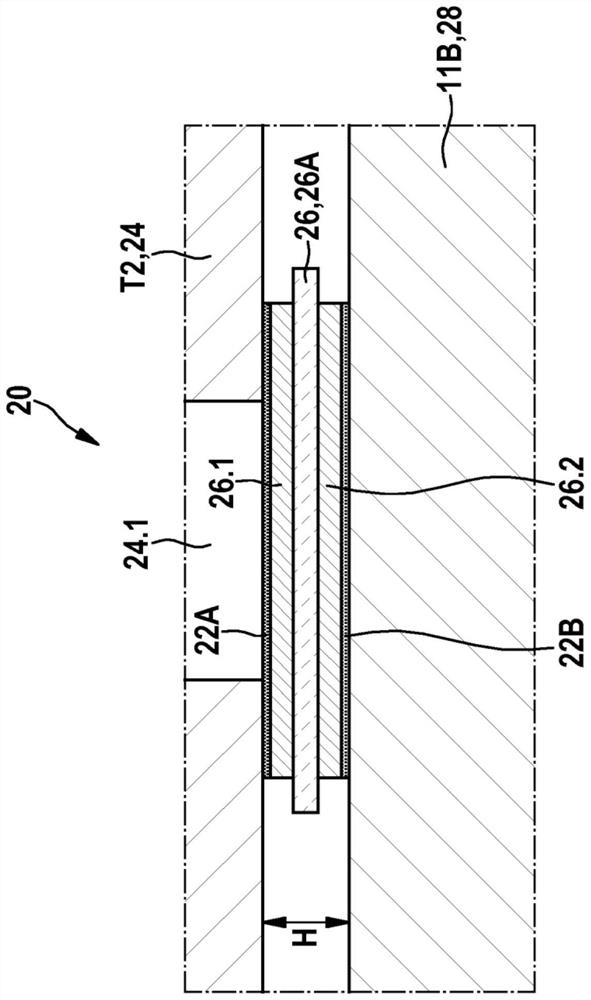

[0020] from figure 1 with figure 2 It can be seen that the illustrated embodiment of the heat extraction assembly 20 for a semiconductor power module 1 according to the invention comprises three stacked bonding partners 24, 26, 28, which are passed through a first solder Layer 22A and second solder layer 22B are connected to one another in a materially bonded manner. The first solder layer 22A is formed between the conductive first bonding partner 24 and the electrically insulating intermediate bonding partner 26 . The second solder layer 22B is formed between the electrically insulating intermediate bonding partner 26 and the electrically conductive second bonding partner 28 . In this case, the first bonding partner 24 is a first conductor track of the semiconductor power module 1 to be dissipated, to which a first electrical potential is applied. The second bonding partner 28 is a second conductor track of the semiconductor power module 1 serving as a heat sink, on which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com