Electronic positioning roller shearing machine

A technology of electronic positioning and rolling shears, which is applied in the direction of shearing devices, shearing machine equipment, shearing machine accessories, etc., can solve the problems of tab deformation, grid deformation, grid strength reduction, etc., to reduce deformation , High cutting efficiency, and the effect of improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

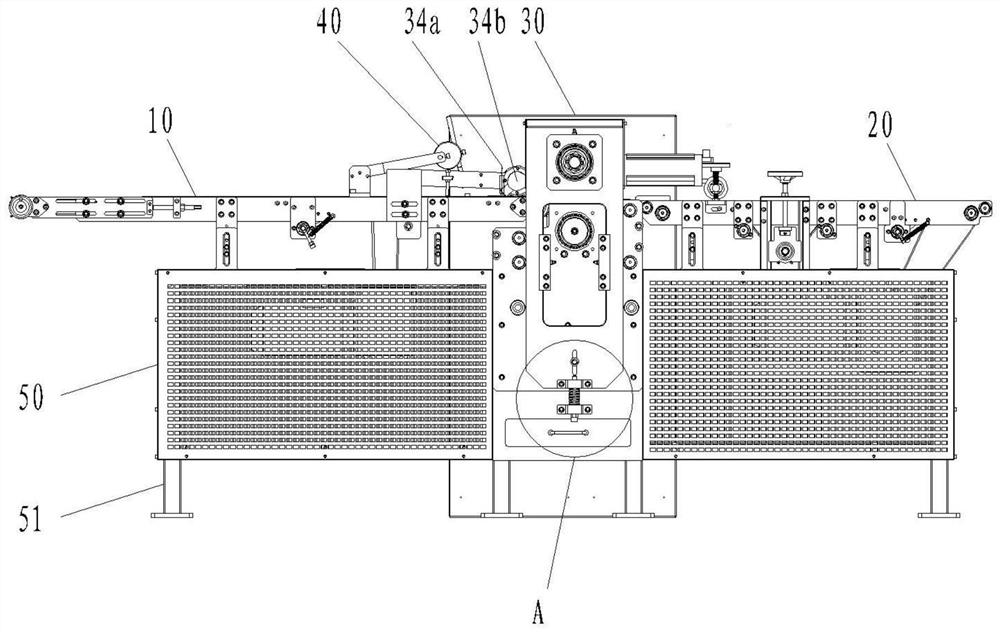

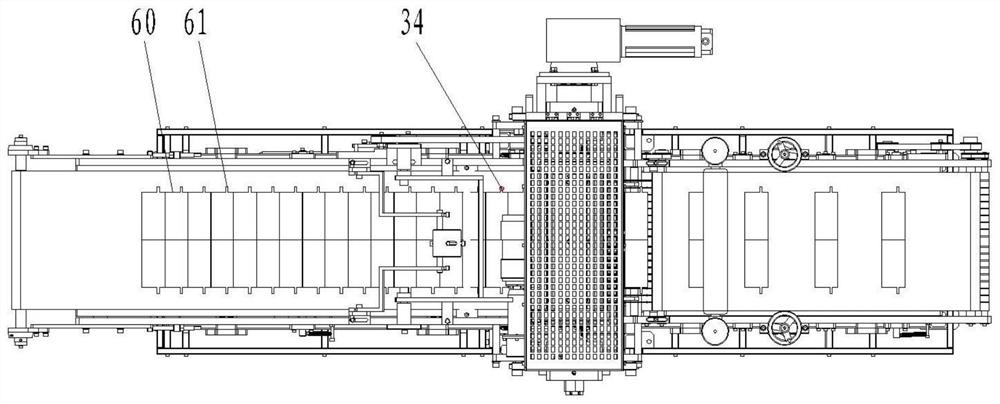

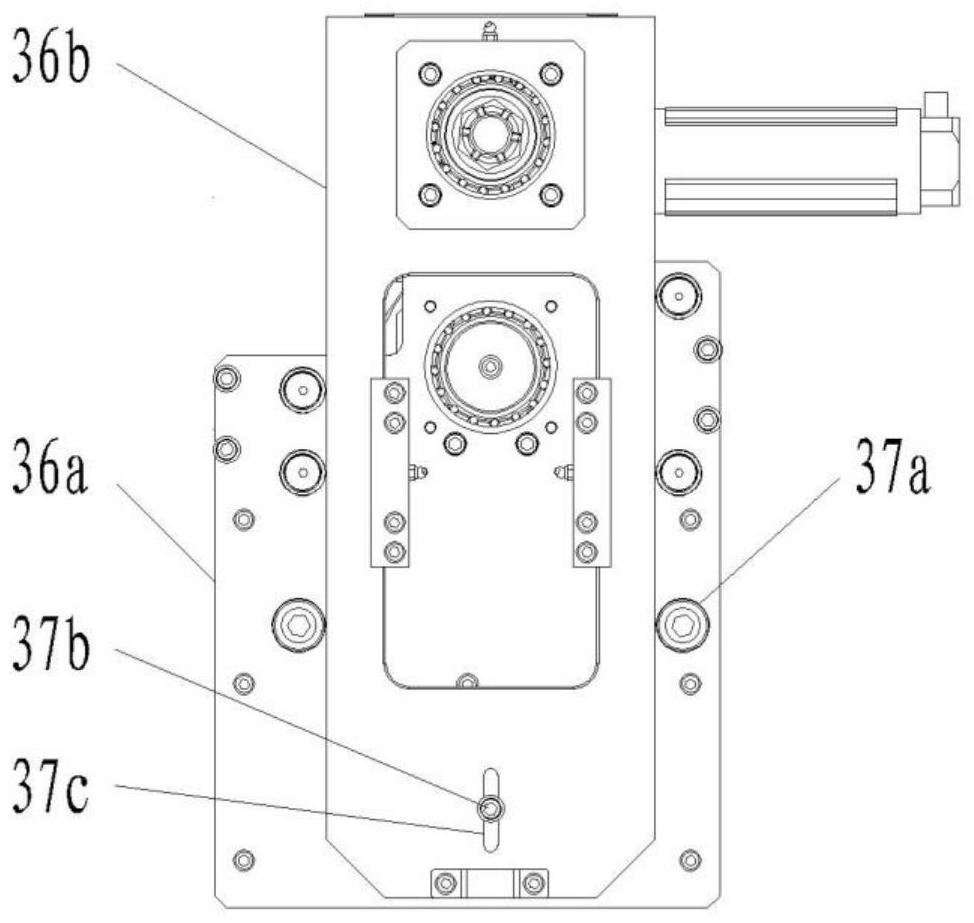

[0024] The electronic positioning rolling shearing machine of the present embodiment comprises a front conveyor belt 10 and a rear conveyor belt 20 which are arranged flush and transported in the same direction, and a rolling cutting device 30 installed between the front conveyor belt and the rear conveyor belt. The device comprises a hob frame, a lower roller 31 and an upper roller 32 which are rotatably mounted on the hob frame and a positioning sensor. It is also installed on the hob frame in a manner that can adjust the center distance vertically. The outer circumference of the upper roller 32 is evenly distributed with a plurality of cutters 33 to cooperate with the lower roller to realize shearing of the grid. The positioning sensor includes a The tab position sensor 34a for detecting the position of the tab, the speed sensor 34b for detecting the transport speed of the grid, and the cutter position sensor 34c for detecting the position of a certain cutter. The flush set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com