Environment-friendly kitchen waste treatment device with solid-liquid separation function

A kitchen waste and solid-liquid separation technology, which is applied in grain processing, manufacturing tools, engine sealing, etc., can solve the problem of poor solid-liquid separation effect, affecting users' experience of using waste disposal devices, and affecting users' follow-up treatment of waste, etc. problems, to achieve the effect of improving user experience, good solid-liquid separation function, and rich functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

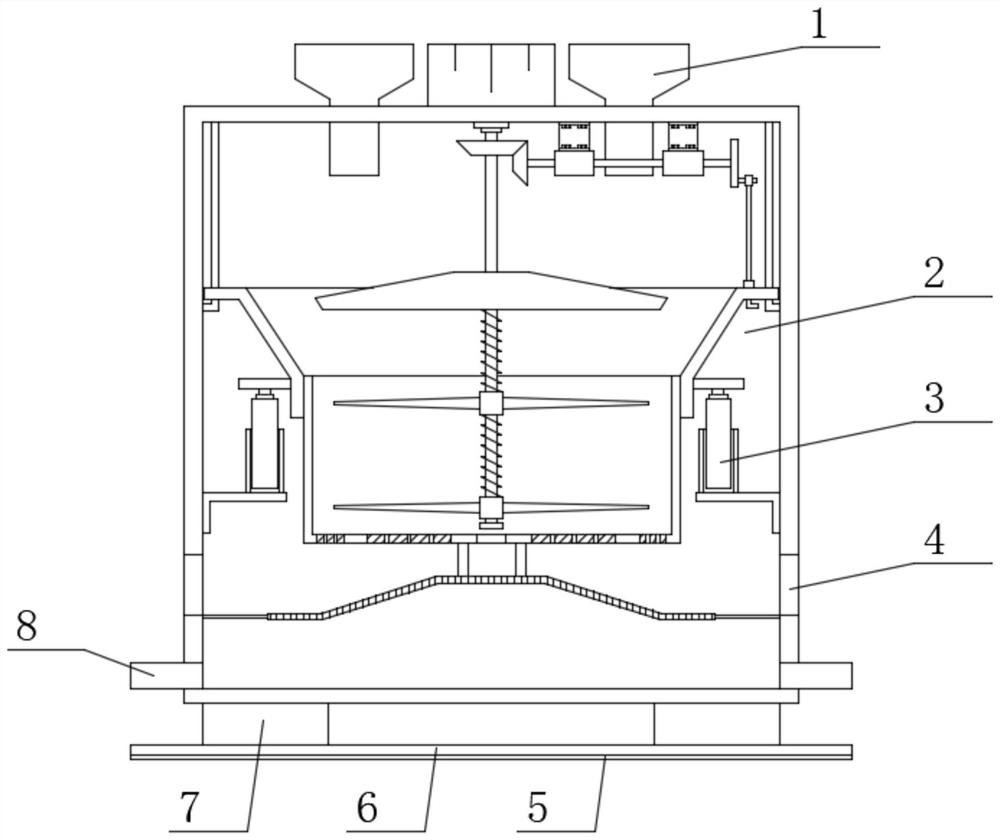

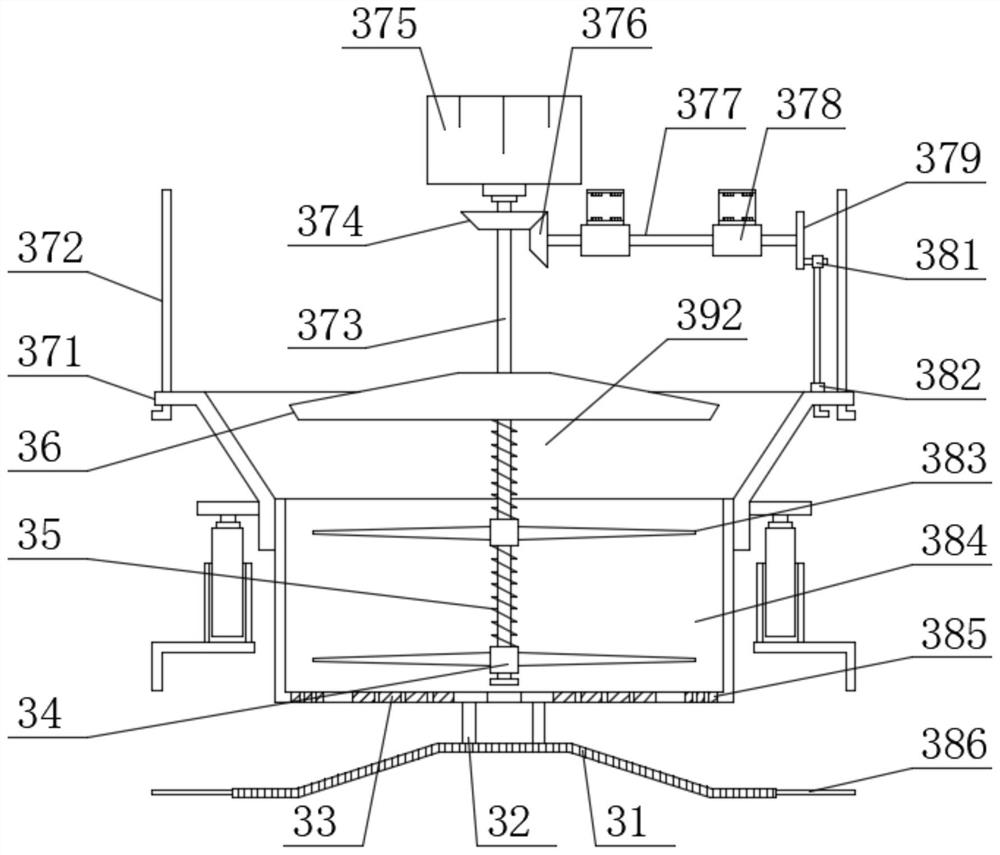

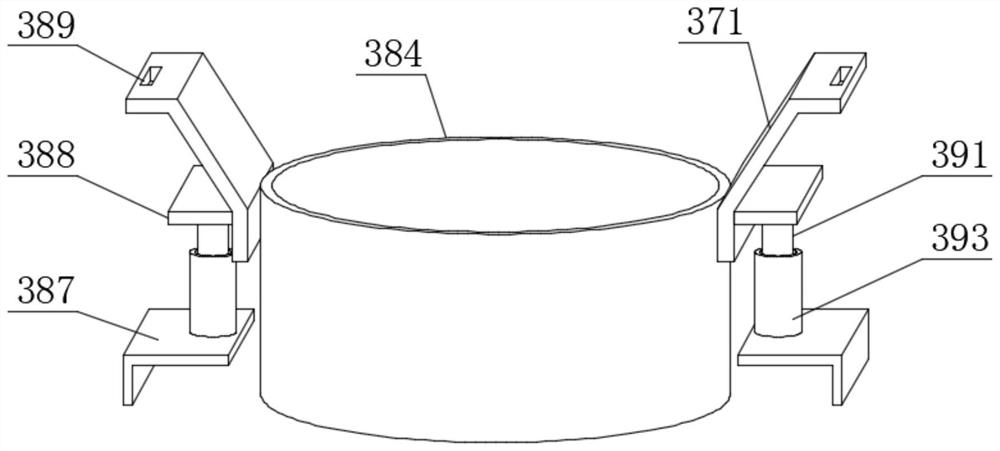

[0023] see Figure 1-Figure 3 , the present invention provides a technical solution: an environment-friendly kitchen waste treatment device with solid-liquid separation function, comprising a crushing box 2, the two ends of the upper surface of the crushing box 2 are fixed with a feeding hopper 1 by welding, the crushing box The bottom end of 2 is welded with drain pipe 8, and the inside of crushing box 2 is provided with crushing mechanism 3, and crushing mechanism 3 comprises driving motor 375, and driving motor 375 is fixedly connected with crushing box 2 by bolt, and the output end of driving motor 375 is welded The transmission square shaft 373 is fixedly connected with the transmission square shaft 373, the top of the transmission square shaft 373 is fixedly connected with the extrusion plate 36 by welding, the bottom end of the transmission square shaft 373 is slidingly connected with the first limit sliding sleeve 34, and the first limit sliding sleeve The two sides of...

Embodiment 2

[0032] On the basis of Embodiment 1, in order to make the shock absorption effect of the garbage disposal device better, in this embodiment, preferably, the two ends of the lower surface of the crushing box 2 are provided with rubber support blocks 7, and the rubber support blocks 7 have a rectangular parallelepiped structure. , the rubber support block 7 is connected with the crushing box 2 by glue bonding, and is supported and shock-absorbed by the rubber support block 7 during use;

[0033] In order to make the use of the garbage disposal device more reliable, in the present embodiment, preferably, the bottom of the crushing box 2 is provided with a support base plate 6, the support base plate 6 is a cuboid structure, and the support base plate 6 and the rubber support block 7 are fixedly connected by screws. At the same time, the support base plate 6 plays a supporting role, so that the use of the garbage disposal device is more reliable;

[0034] In order to make the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com