High-temperature laminating machine capable of achieving heating through heat pipes and hot oil

A pressing machine, high temperature technology, applied in the field of heat pipe hot oil heating high temperature pressing machine at the same time, can solve the problems of easy oxidation of cooling water channels, long heating and cooling time, insufficient uniformity of plate surface temperature, etc., to achieve improvement Process and use requirements, product qualification rate improvement, and the effect of excellent equipment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

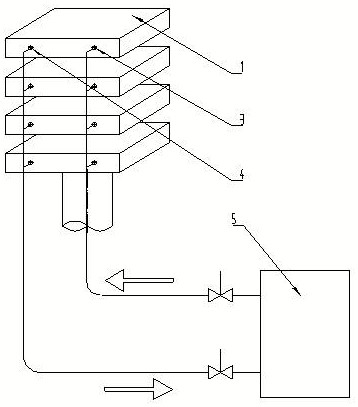

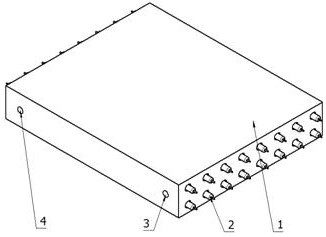

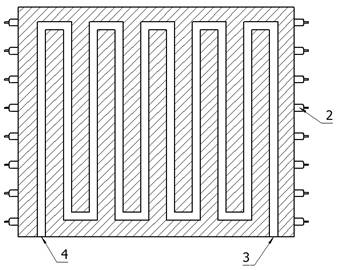

[0017] The present invention is described in further detail with specific embodiment now in conjunction with accompanying drawing:

[0018] A heat pipe hot oil simultaneously heating high-temperature pressing machine, which is provided with three rows of holes in parallel in the hot plate 1 of the high-temperature pressing machine, and electric heating tubes 2 are built in the upper and lower rows of holes, which is the hot plate 1 of the high-temperature pressing machine Radiation heat transfer on both sides, the middle row is provided with interconnected S-shaped holes for heating and cooling channels, which is replaced by the medium water of the heating and cooling channels in the middle layer of the hot plate 1 of the high-temperature press machine with the effect of temperature-changing oil Heat transfer oil, imported heat transfer oil THERMINOL VP-1 material or domestic DX330 can be used for heat transfer oil, the heat transfer oil is heated or cooled by the heat transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com