Quartz mineral powder impurity removal system and impurity removal process

A mineral powder and quartz technology, which is applied in the field of quartz mineral powder impurity removal system and impurity removal process, can solve the problems of large differences in mineralization of quartz minerals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

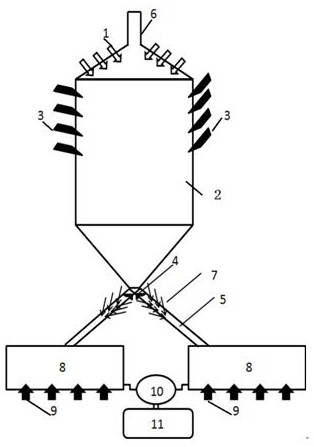

[0026] A quartz mineral powder impurity removal system, comprising a high-temperature furnace 2, a refractory channel 5, a pickling pool 8, a filter 10, and a dryer 11 connected in sequence; a powder feeding spray gun 1 and a flame spray gun 3 are arranged in the high-temperature furnace , the powder feeding spray gun is located above the flame spray gun, the top of the high-temperature furnace is provided with an exhaust channel 6, the discharge port at the bottom of the high-temperature furnace is connected to the refractory channel 5, and the bottom of the refractory channel is connected to the feed port of the pickling pool The discharge port at the bottom of the pickling tank is connected to the filter, and the solid discharge port at the bottom of the filter is connected to the dryer.

[0027] The high-temperature furnace includes a powder feeding area, a flame combustion area and a feeding area from top to bottom in sequence. The powder feeding area is in the shape of a ...

Embodiment 2

[0036] A process for removing impurities from quartz mineral powder, the process utilizes the system described in Embodiment 1 to remove impurities, specifically comprising the following steps:

[0037] First, the quartz mineral powder with a purity of 2N or more is injected into the flame combustion zone of the high-temperature furnace from the top of the high-temperature furnace with hydrogen-oxygen flame combustion by using the purified dry compressed air as the carrier gas through the powder-feeding spray gun. Quartz mineral powder is directly melted under high temperature, and formed into balls by means of surface tension, and the solid density increases immediately, and begins to settle to the lower part of the high-temperature furnace, and is partially cooled during the settlement process.

[0038] Furthermore, the particles that settle to the bottom of the high-temperature furnace enter the refractory channel obliquely connected to the bottom of the high-temperature fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com