Hydraulic slide valve internal leakage detection method based on acoustic emission technology

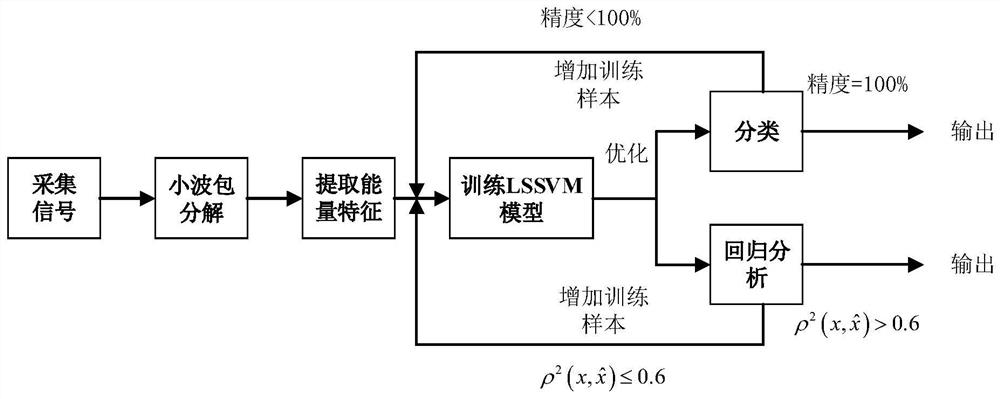

An acoustic emission technology and hydraulic slide valve technology, which are applied in the field of leakage detection in hydraulic slide valves, can solve the problems of the accuracy of detection or prediction results and the unsatisfactory processing speed, and achieve the advantages of short prediction time, improved efficiency and improved prediction accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

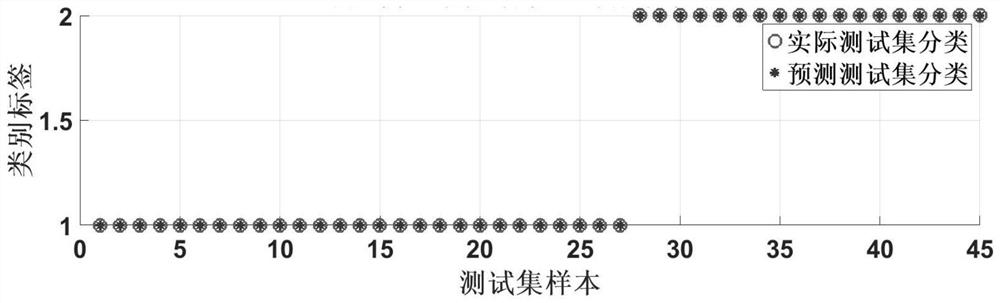

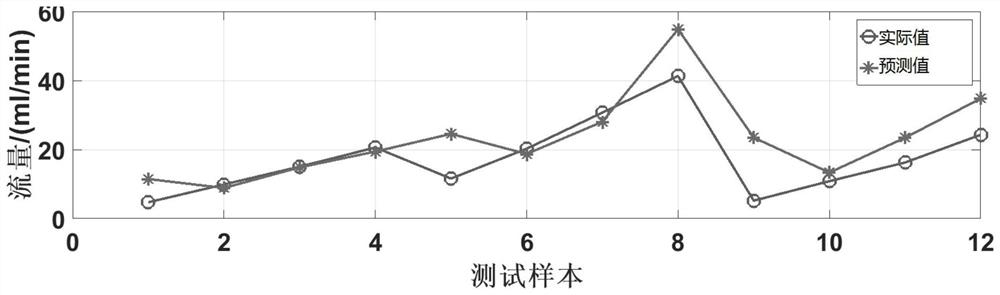

[0045] Taking a certain type of hydraulic slide valve as an example for leak detection, the specific steps are as follows:

[0046] S1: Pressurize 5 groups of hydraulic slide valves (1-12MPa, 1MPa each time), collect the experimental data of internal leakage detection, the data are the acoustic emission signals and leakage of normal slide valves and internal leakage slide valves under different pressures ;

[0047] S2: Select the db8 wavelet base to perform 6-layer wavelet packet decomposition on the acoustic emission signal, and extract the energy characteristics of each sub-band;

[0048] S3: using the sub-band energy characteristics obtained in S2 under the pressure of 1-3MPa as the training sample of the detection model, and using the least squares support vector machine method to train the detection model of the spool valve internal leakage;

[0049] S4: Select the radial basis kernel function as the kernel function of the detection model, and use the artificial bee colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com