Temperature monitoring device and method for motor of conveying unit and circulating type conveying system

The technology of a conveying system and a conveying unit is applied in the field of a temperature monitoring device for a motor of a conveying unit and a circulating conveying system, which can solve the problems of a large number of motors, increase costs, and limited promotion, and achieve saving of labor and material costs, The effect of improving production efficiency and avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

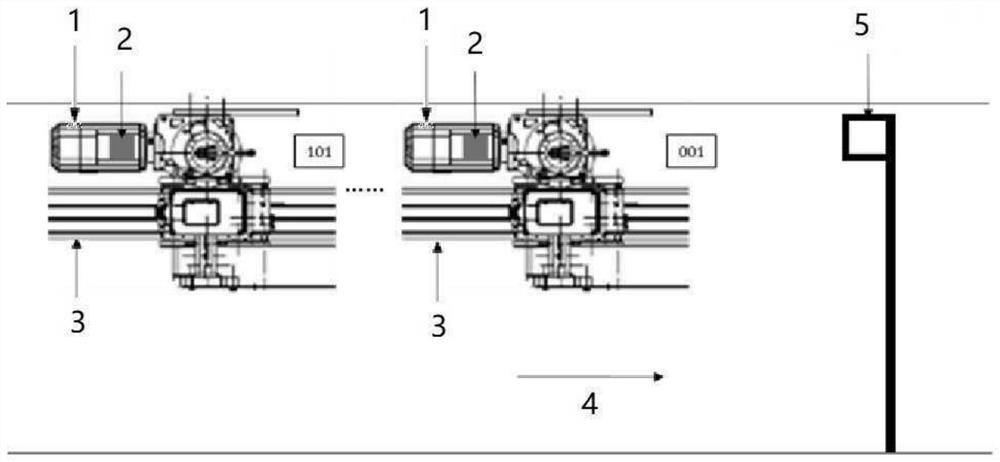

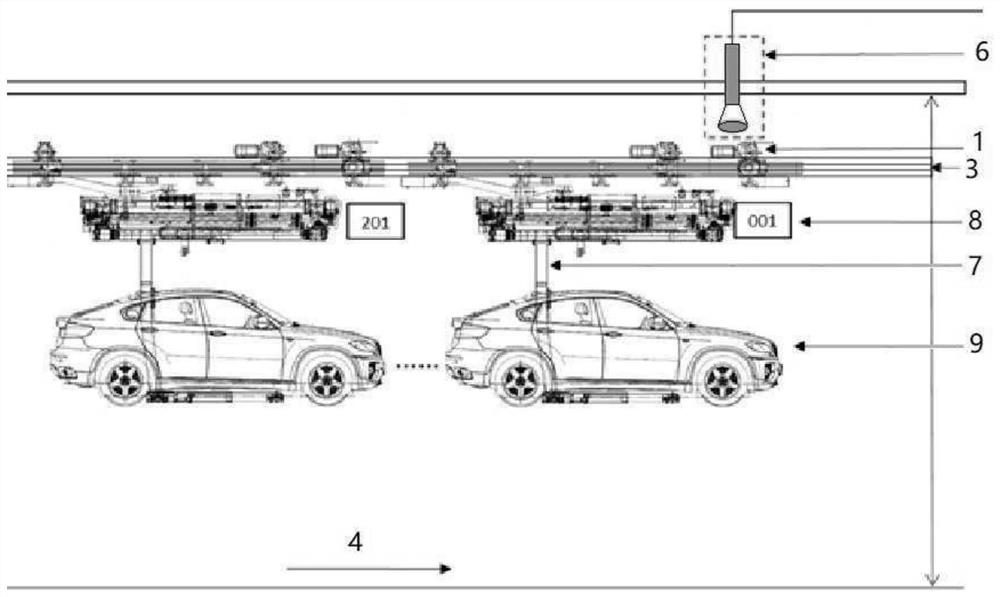

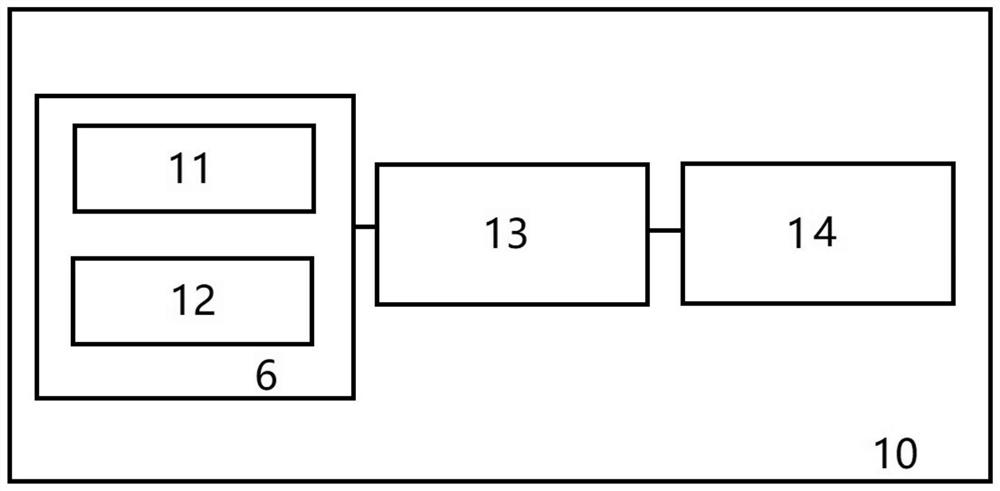

[0059] figure 1 Shown is a prior art temperature measurement of a motor 1 in a vehicle manufacturing line, ie in a conveying system. The motor 1 is used to drive a conveyor unit (not shown in detail) on a support beam 3 of the conveyor system and / or to adjust the height of the conveyor unit. In the illustration shown, a plurality of conveyor units 001 to 101 on a support beam 3 are each assigned an electric motor 1 for moving the respective conveyor unit in the advancing direction 4 . A shaded temperature sensor 2 is attached to each motor 1 . When the motor passes a fixed position where the reading device 5 is installed, the reading device 5 non-contactly reads the temperature of the motor measured by the temperature sensor 1 . In temperature measurement according to the prior art, it is unavoidable to install temperature sensors 2 for a large number of motors. Since the temperature sensor 2 needs to be powered separately and uniquely numbered, additional costs are incurre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com